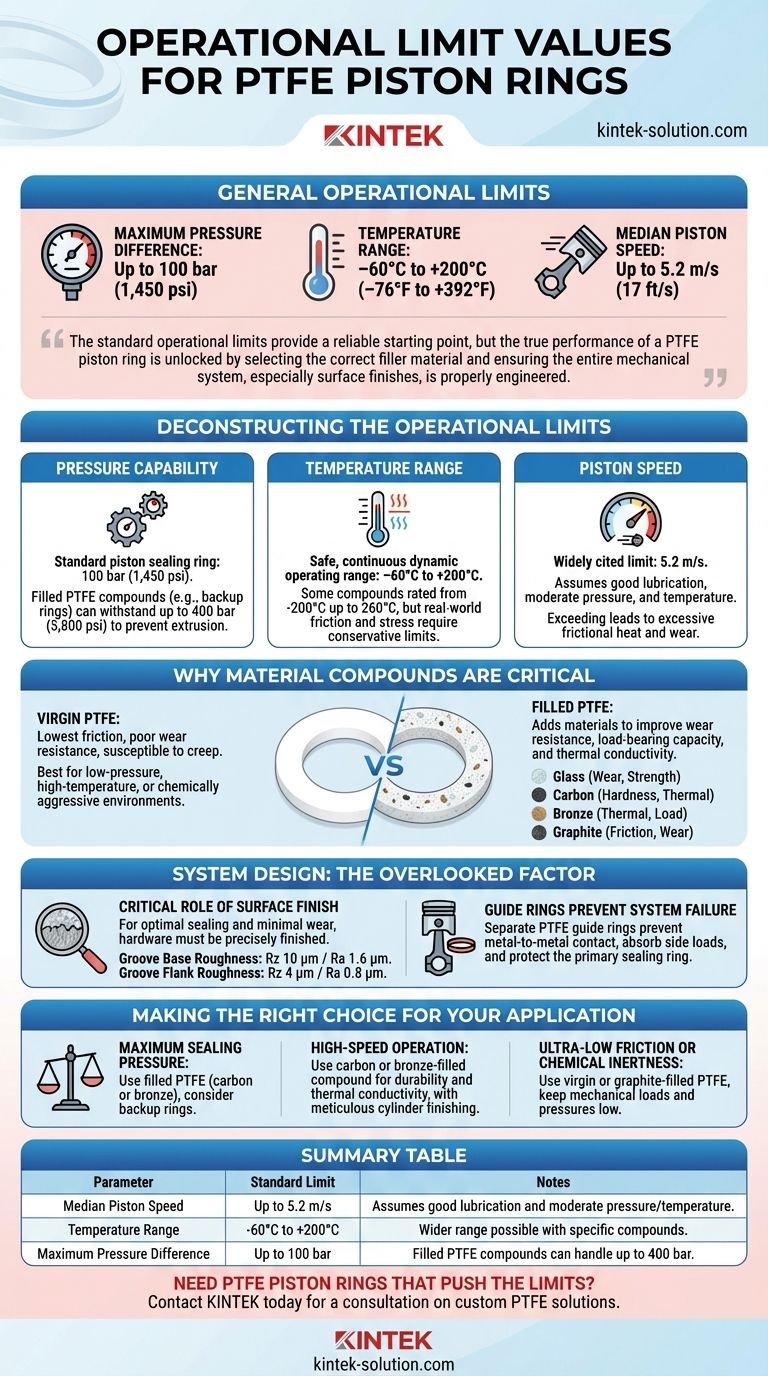

In short, the general operational limits for PTFE piston rings are a median piston speed up to 5.2 m/s, a temperature range of –60°C to +200°C (–76°F to +392°F), and a maximum pressure difference of up to 100 bar (1,450 psi). However, these values represent a baseline and can change significantly based on the specific material composition and system design.

The standard operational limits provide a reliable starting point, but the true performance of a PTFE piston ring is unlocked by selecting the correct filler material and ensuring the entire mechanical system, especially surface finishes, is properly engineered.

Deconstructing the Operational Limits

The headline figures for speed, pressure, and temperature are interdependent. Pushing one limit often requires reducing another. Understanding the nuance behind each value is critical for successful implementation.

H3: Pressure Capability

The most common operational limit for a standard PTFE piston sealing ring is a pressure difference of 100 bar (1,450 psi).

However, the raw material can handle far more. Filled PTFE compounds (blended with glass, carbon, or bronze) used in components like backup rings can withstand pressures up to 400 bar (5,800 psi). These rings are designed to prevent the extrusion of softer seals, a different function from dynamic piston sealing.

H3: Temperature Range

A safe, continuous operating temperature range for dynamic applications is –60°C to +200°C (–76°F to +392°F).

The PTFE material itself can endure a wider range, with some compounds rated from -200°C (-328°F) up to 260°C (500°F). The more conservative range accounts for heat generated by friction in a dynamic system and other real-world operating stresses.

H3: Piston Speed

The widely cited limit is a median piston speed of 5.2 m/s (17 ft/s).

This value assumes good lubrication (even if minimal), moderate pressure, and operating temperatures within the standard range. Exceeding this speed can lead to excessive frictional heat and accelerated wear, especially in non-lubricated or high-pressure systems.

Why Material Compounds are Critical

"PTFE" is rarely used in its pure, virgin state for demanding applications. The base polymer is blended with fillers to enhance specific properties, directly impacting its operational limits.

H3: Virgin vs. Filled PTFE

Virgin PTFE offers the lowest coefficient of friction but has poor wear resistance and is susceptible to "creep" or deformation under load. It's best for low-pressure, high-temperature, or chemically aggressive environments where friction is the primary concern.

Filled PTFE adds materials like glass, carbon, bronze, or graphite to the PTFE base. These fillers dramatically improve wear resistance, load-bearing capacity, and thermal conductivity.

H3: The Impact of Common Fillers

- Glass: Greatly increases wear resistance and compressive strength.

- Carbon: Improves hardness, compressive strength, and thermal conductivity.

- Bronze: Provides the best thermal conductivity and heavy load resistance but has lower chemical resistance.

- Graphite: Reduces the coefficient of friction and improves wear properties, often used in combination with other fillers.

The choice of filler is a direct trade-off between various performance characteristics and is dictated entirely by the application's demands.

System Design: The Overlooked Factor

A PTFE ring does not perform in a vacuum. Its operational limits are only achievable when the surrounding mechanical components are correctly prepared.

H3: The Critical Role of Surface Finish

For optimal sealing and minimal wear, the hardware surfaces must be precisely finished. Poor surface finish will abrade the ring, causing premature failure.

- Groove Base Roughness: Rz 10 µm / Ra 1.6 µm

- Groove Flank Roughness: Rz 4 µm / Ra 0.8 µm

H3: Guide Rings Prevent System Failure

In many applications, separate PTFE guide rings are used alongside the piston ring. Their sole purpose is to prevent metal-to-metal contact between the piston and the cylinder, absorbing side loads and protecting the primary sealing ring from damage.

Making the Right Choice for Your Application

The operational limits are not a simple checklist but a guide for engineering decisions. Use your primary goal to determine the best approach.

- If your primary focus is maximum sealing pressure: You must use a filled PTFE compound (carbon or bronze) and may need to incorporate backup rings into your design.

- If your primary focus is high-speed operation: A carbon or bronze-filled compound is essential for its durability and thermal conductivity, paired with meticulous cylinder surface finishing.

- If your primary focus is ultra-low friction or chemical inertness: Virgin or graphite-filled PTFE is the correct choice, but you must keep mechanical loads and pressures relatively low.

Ultimately, achieving reliable performance at the edge of these limits requires matching the specific PTFE compound and system design to your unique operational demands.

Summary Table:

| Parameter | Standard Limit | Notes |

|---|---|---|

| Median Piston Speed | Up to 5.2 m/s | Assumes good lubrication and moderate pressure/ temperature. |

| Temperature Range | -60°C to +200°C | Wider range possible with specific compounds. |

| Maximum Pressure Difference | Up to 100 bar | Filled PTFE compounds can handle up to 400 bar. |

Need PTFE Piston Rings That Push the Limits?

Navigating the interplay of speed, pressure, and temperature is complex. KINTEK specializes in manufacturing high-performance PTFE components, including custom piston rings, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. We help you select the right filler material and design for your specific application, ensuring reliability even at the edge of operational limits.

Contact KINTEK today for a consultation on custom PTFE solutions, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is glass-filled PTFE used in construction? Enhance Structural Integrity & Durability

- In what types of environments should PTFE seals be considered? Ensure Reliability in Extreme Conditions

- What types of PTFE processing machines are commonly used? From Extrusion to Precision Machining

- What modifications are made to standard PTFE to improve thermal properties? Enhance Performance with Filled PTFE

- What are the key properties of PTFE that make it useful in sports equipment? Boost Speed and Durability

- What are the advantages of PTFE liners in medical catheter applications? Enhance Performance & Patient Safety

- Why are PTFE lined pipes considered essential for certain industries? Unmatched Corrosion Resistance & Purity

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance