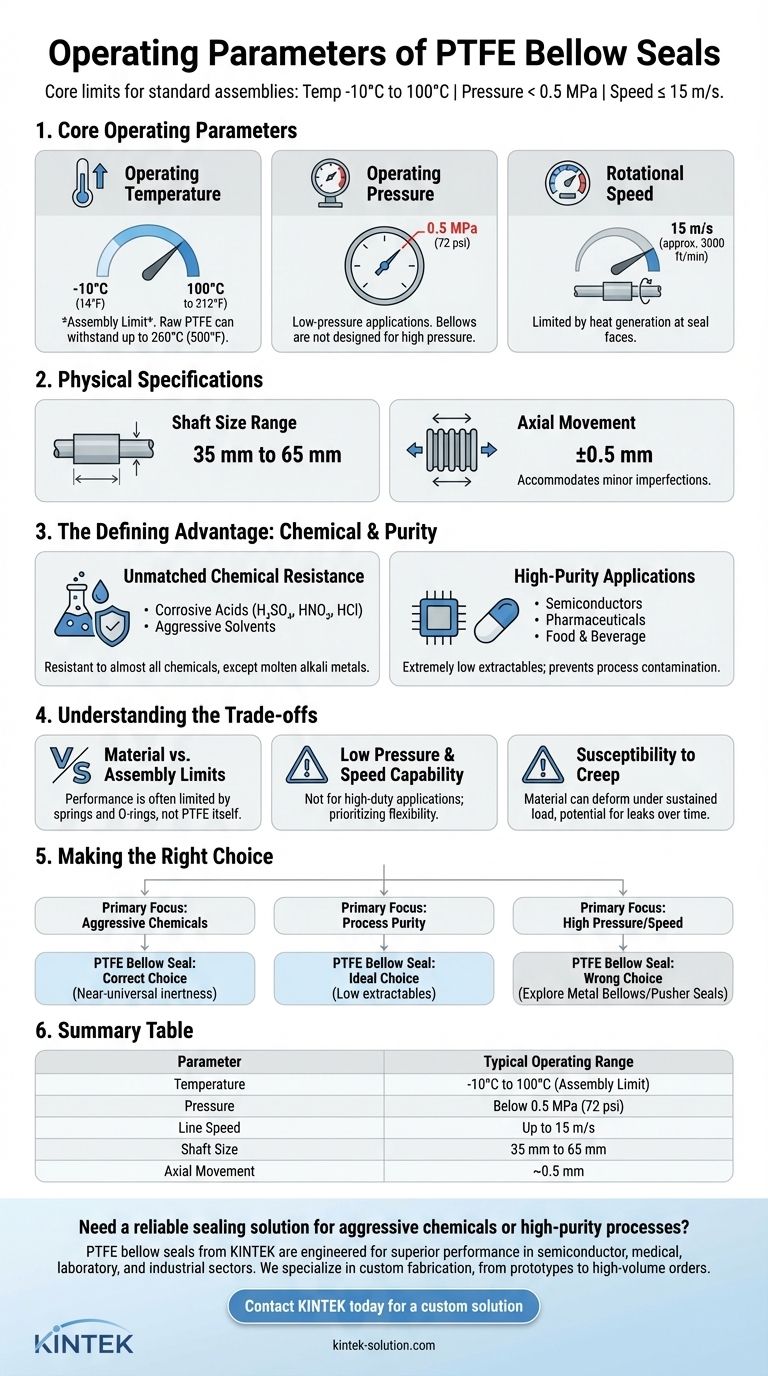

In short, the typical operating parameters for a standard PTFE bellow seal assembly are a temperature range of -10°C to 100°C, pressure below 0.5 MPa, and a line speed of up to 15 m/s. However, these numbers represent the limits of the entire seal assembly, not the PTFE material itself, which has a much broader operational range.

The key to understanding PTFE bellow seals is recognizing the difference between the exceptional properties of the PTFE material and the practical limits of the complete mechanical seal design. The seal is chosen for PTFE's near-universal chemical resistance and purity, but its performance is ultimately defined by the engineering of the entire assembly.

The Core Operating Parameters

A mechanical seal is a system of components. While the PTFE bellows are the heart of the seal, other parts like springs, drive mechanisms, and secondary seals often define the final operating limits.

Operating Temperature

The temperature range provided in documentation, such as -10°C to 100°C (14°F to 212°F), typically refers to the limitation of the entire seal assembly.

The raw PTFE material itself has a vastly wider service temperature range, capable of functioning in cryogenic conditions and at continuous high temperatures up to 260°C (500°F). The narrower range of the complete seal is often due to other materials used in its construction.

Operating Pressure

PTFE bellow seals are fundamentally designed for low-pressure applications, generally specified for pressures below 0.5 MPa (or 72 psi).

The flexible, convoluted nature of the bellows, which allows it to compensate for shaft movement, is not suited to contain high pressures. Attempting to use them in high-pressure environments will lead to distortion and seal failure.

Rotational Speed

A typical limit for line speed is around 15 m/s (approx. 3000 ft/min). PTFE has a low coefficient of friction, which is beneficial for reducing heat generation at the seal faces.

However, at higher speeds, managing the heat generated at the mating surfaces becomes the primary challenge, as excessive heat can damage the seal components.

Physical Specifications

These seals are available in common shaft sizes, with a typical specification range of 35 mm to 65 mm.

They are designed to accommodate minor imperfections in the equipment, with a typical axial movement tolerance (or "channeling") of around 0.5 mm. This flexibility is a key advantage of the bellow design.

The Defining Advantage: Chemical and Purity Performance

Engineers specify PTFE bellow seals not for extreme pressure or speed, but for their unique material advantages in demanding environments.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is unaffected by highly corrosive media like concentrated sulfuric acid, nitric acid, or hydrochloric acid, even under boiling conditions.

The only common exceptions are molten alkali metals and certain exotic fluorinating agents. This makes it the default choice for sealing pumps and mixers in aggressive chemical processing.

Suitability for High-Purity Applications

In industries like pharmaceuticals and semiconductors, preventing process contamination is critical. PTFE is inherently a very pure material.

These seals exhibit extremely low levels of leachable metals, with lead content often below 10⁻¹¹ g/ml and uranium below 10⁻¹² g/ml. This ensures the product being processed remains uncontaminated by the seal itself.

Understanding the Trade-offs

To use a PTFE bellow seal effectively, you must understand its limitations. The choice involves balancing its chemical superiority against its mechanical constraints.

Material vs. Assembly Limits

This is the most common point of confusion. Always verify if the published limits refer to the PTFE material or the complete, assembled seal. The performance of springs and secondary O-rings can significantly narrow the operational window, especially for temperature.

Low Pressure and Speed Capability

Reiterating this crucial point: PTFE bellow seals are not a solution for high-duty applications. Their design prioritizes chemical compatibility and flexibility over pressure and speed handling. Pushing them beyond their rated limits is a primary cause of failure.

Susceptibility to Creep

PTFE can be subject to "creep" or "cold flow," where the material slowly deforms under a sustained load. In a seal, this can happen over time, especially at elevated temperatures, potentially reducing the sealing force at the faces and leading to leaks. Proper seal design and material selection help mitigate this, but it is an inherent property of the material.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its strengths to your primary operational goal. Always consult the specific manufacturer's data sheet for the exact model you are considering.

- If your primary focus is aggressive chemical service: A PTFE bellow seal is almost always the correct choice due to its near-universal inertness.

- If your primary focus is process purity: The extremely low level of extractables makes PTFE an ideal material for semiconductor, pharmaceutical, or food-grade applications.

- If your primary focus is high pressure or high speed: A PTFE bellow seal is likely the wrong choice. You should explore other seal designs, such as metal bellows or pusher seals with more robust face material combinations.

By understanding that a seal's performance is a function of its complete design, you can confidently select a solution that ensures reliability in your specific application.

Summary Table:

| Parameter | Typical Operating Range |

|---|---|

| Temperature | -10°C to 100°C (Assembly Limit) |

| Pressure | Below 0.5 MPa (72 psi) |

| Line Speed | Up to 15 m/s |

| Shaft Size | 35 mm to 65 mm |

| Axial Movement | ~0.5 mm |

Need a reliable sealing solution for aggressive chemicals or high-purity processes?

PTFE bellow seals from KINTEK are engineered for superior performance where chemical resistance and product purity are paramount. Our seals are ideal for the semiconductor, medical, laboratory, and industrial sectors.

We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit for your specific application requirements.

Contact KINTEK today to discuss your project and get a custom solution that delivers reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications