In the medical field, Polytetrafluoroethylene (PTFE) is a cornerstone material used for applications ranging from low-friction coatings on surgical tools to life-saving permanent implants. Its utility is found in catheters, guidewires, cardiovascular grafts, heart patches, and surgical sutures, where its unique properties reduce patient risk and improve procedural outcomes.

The core reason for PTFE's widespread medical use is not a single feature, but its rare combination of three key properties: extreme lubricity (low friction), chemical inertness (biocompatibility), and a non-stick surface. This trio makes it exceptionally suitable for devices that must interact safely and cleanly with the human body.

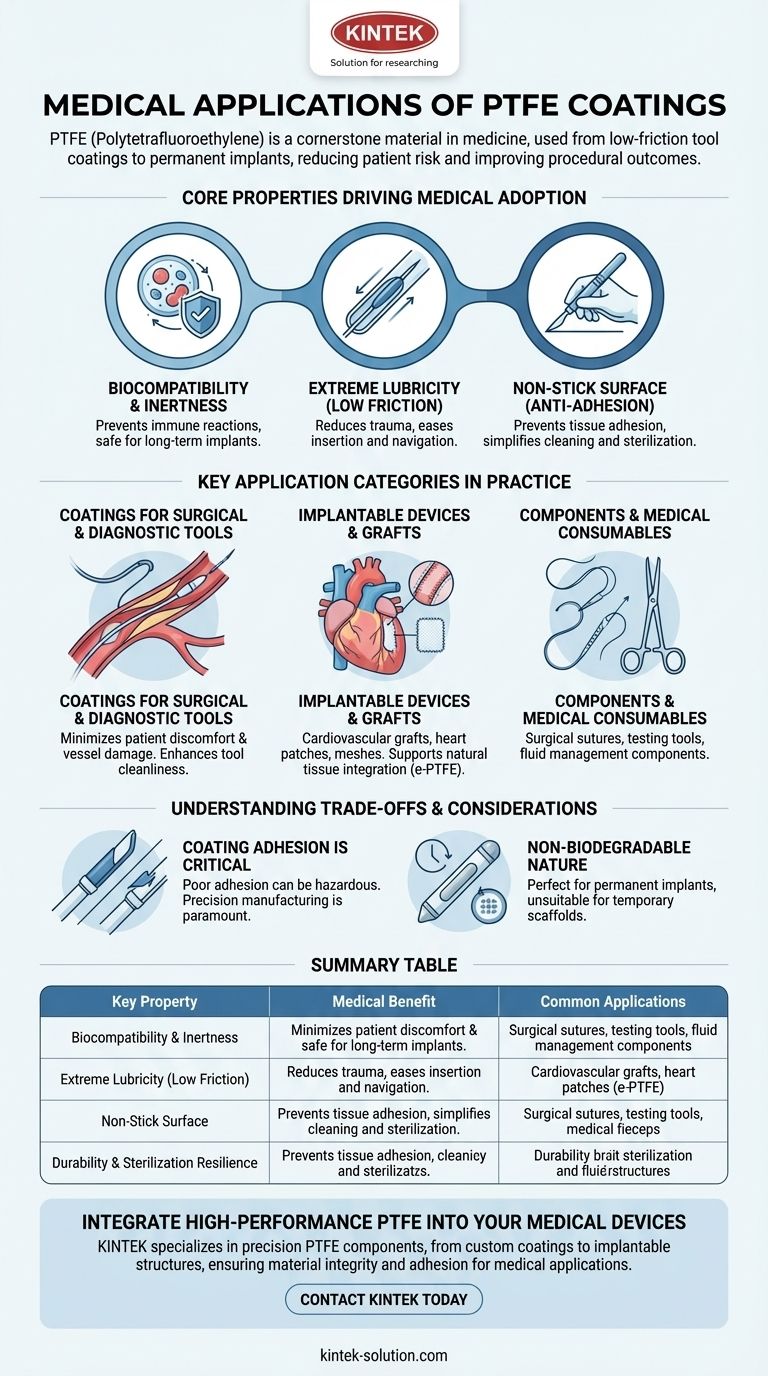

The Core Properties Driving Medical Adoption

To understand PTFE's applications, we must first understand the fundamental material science that makes it so valuable. Its selection for a medical device is never arbitrary; it is a direct consequence of its inherent physical and chemical characteristics.

Unmatched Biocompatibility and Inertness

PTFE is biologically inert, meaning the human body does not recognize it as a foreign substance. This prevents immune reactions, rejection, or other adverse physiological side effects, making it ideal for long-term implantation.

Its chemical inertness also means it does not react with or degrade when exposed to bodily fluids or aggressive sterilization chemicals.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid. This property, often called lubricity, is critical for devices that must pass through sensitive tissues.

This allows tools like catheters and guidewires to navigate blood vessels with minimal resistance, which reduces trauma to the patient and lowers the risk of complications.

Non-Stick Surface (Anti-Adhesion)

The non-stick quality of PTFE prevents biological materials like blood, bacteria, and tissue from adhering to a device's surface.

For surgical instruments such as forceps, this simplifies cleaning and enhances the effectiveness of sterilization. For wound dressings, it means they can be removed without damaging newly formed tissue.

Durability and Sterilization Resilience

Medical devices must withstand rigorous sterilization protocols. PTFE is highly durable and can be sterilized by any common method, including autoclaving and radiation, without degrading.

Its high resistance to radiation also makes it a suitable material for shielding components in radiological equipment like X-ray machines.

Key Application Categories in Practice

These core properties translate directly into three primary categories of medical use: coatings for instruments, implantable structures, and essential surgical components.

Coatings for Surgical and Diagnostic Tools

The most common application is a thin PTFE coating applied to another material, typically stainless steel.

Catheters and guidewires are coated to ensure they can be inserted and maneuvered smoothly. This minimizes patient discomfort and reduces the risk of damaging the interior walls of blood vessels.

Surgical instruments also benefit from these coatings, which prevent tissue adhesion and make the tools easier to clean between procedures.

Implantable Devices and Grafts

PTFE's biocompatibility makes it a premier material for devices that remain inside the body permanently. These include cardiovascular grafts for repairing arteries, patches to repair defects in the heart, and even synthetic ligament replacements.

A special form, expanded PTFE (e-PTFE), has a microporous structure. This allows the patient's own tissue to grow into the graft, creating a strong, natural integration. This is used for artificial blood vessels and soft tissue regeneration patches.

Other implantable uses include surgical meshes for hernia repair and components for pacemakers and artificial joints.

Components and Medical Consumables

Beyond coatings and large implants, PTFE is used to manufacture entire components. Its strength and flexibility make it an excellent material for surgical sutures.

It is also used for forceps, various testing tools, and components within fluid management systems where chemical resistance is critical.

Understanding the Trade-offs and Considerations

While PTFE is exceptionally versatile, it is essential to understand its practical limitations. No material is a universal solution.

Coating Adhesion is Critical

The primary challenge with PTFE coatings is not the material itself, but ensuring it permanently adheres to the substrate (e.g., the metal of a surgical tool). A poorly applied coating can delaminate or flake off, rendering the device useless or even hazardous. The manufacturing process is therefore paramount.

Non-Biodegradable Nature

PTFE's inertness means it is not biodegradable. The body cannot break it down and absorb it over time.

This makes it perfect for permanent implants but unsuitable for applications like temporary scaffolds, where the goal is for the material to dissolve as new tissue grows to replace it.

Making the Right Choice for Your Application

Your choice of material must align directly with the primary goal of the medical device you are designing or selecting.

- If your primary focus is patient comfort and procedural safety: Low-friction PTFE coatings on guidewires, catheters, and other invasive instruments are the industry standard.

- If your primary focus is creating permanent, non-reactive implants: Solid or expanded PTFE is the ideal choice for cardiovascular grafts, surgical meshes, and patches.

- If your primary focus is instrument reusability and sterilization: Non-stick PTFE coatings on tools like forceps and scalpels will significantly improve cleaning efficiency and sterility assurance.

Ultimately, PTFE's role in modern medicine is to create a safer, more effective interface between a medical device and the human body.

Summary Table:

| Key Property | Medical Benefit | Common Applications |

|---|---|---|

| Biocompatibility & Inertness | Prevents immune reaction, safe for long-term implants | Cardiovascular grafts, heart patches, surgical meshes |

| Extreme Lubricity (Low Friction) | Reduces trauma, eases insertion and navigation | Catheter and guidewire coatings, minimally invasive tools |

| Non-Stick Surface | Prevents tissue adhesion, simplifies cleaning and sterilization | Surgical instruments (forceps, scalpels), wound dressings |

| Durability & Sterilization Resilience | Withstands autoclaving and radiation without degrading | Reusable surgical tools, components for radiological equipment |

Ready to integrate high-performance PTFE into your medical device designs?

KINTEK specializes in the precision manufacturing of PTFE components—from custom coatings and seals to complex labware and implantable structures. Our expertise ensures the material integrity and reliable adhesion critical for medical applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume production, we deliver components that meet stringent standards for biocompatibility, durability, and performance.

Contact KINTEK today to discuss how our PTFE solutions can enhance the safety and efficacy of your medical devices.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications