At their core, PTFE and Nylon are both thermoplastics with moderate mechanical strength, but they serve distinct roles in bushings and thrust washers. PTFE excels in applications demanding extremely low friction and higher load capacity, while Nylon offers a balanced, general-purpose profile. The critical difference lies in PTFE's softness and its tendency to deform under constant pressure.

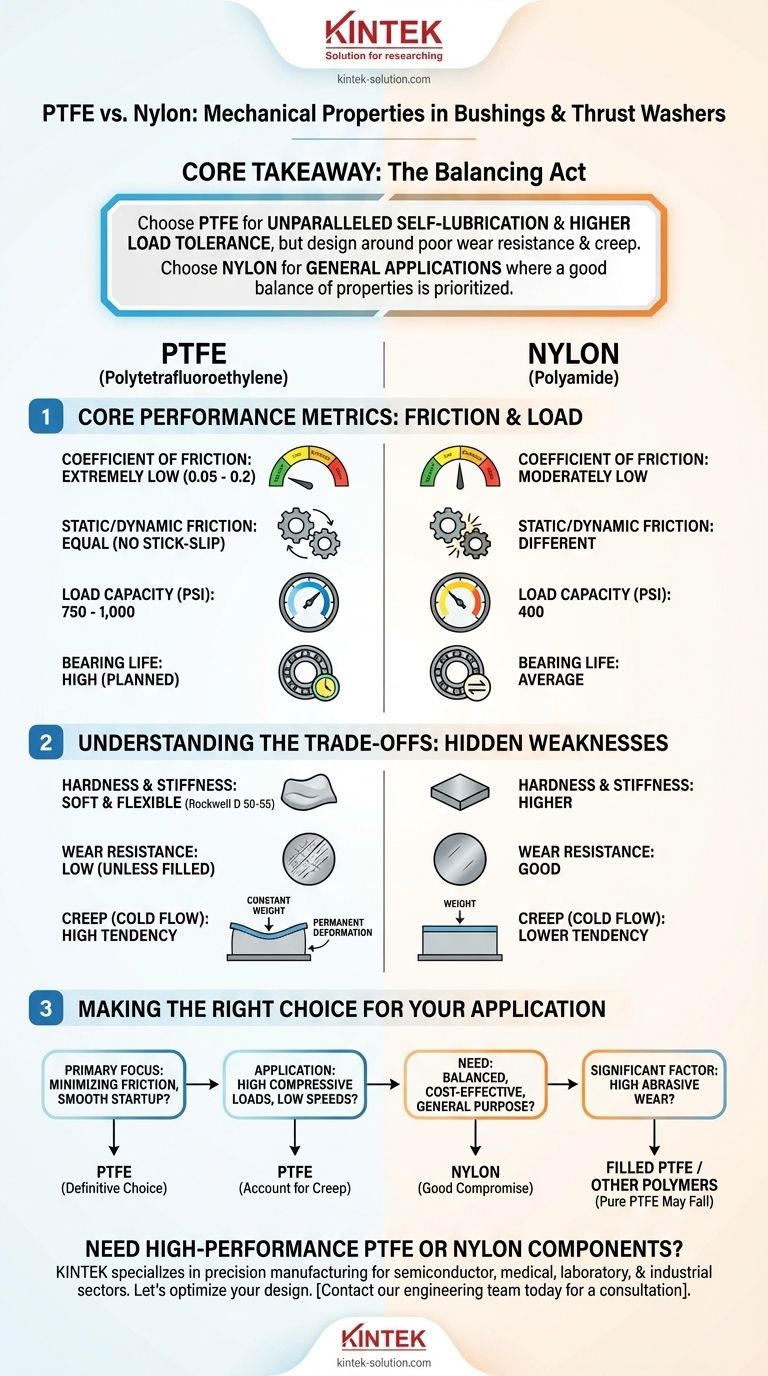

The central takeaway is this: Choose PTFE for its unparalleled self-lubrication and higher load tolerance, but only if you can design around its poor wear resistance and its tendency to "creep." Choose Nylon for general applications where a good balance of properties is more important than best-in-class friction performance.

The Core Performance Metrics: Friction and Load

When selecting a material for a bushing or washer, the primary concerns are almost always friction and the ability to withstand pressure. Here, the two materials show a clear divergence.

Coefficient of Friction: The Defining Advantage of PTFE

PTFE has an extremely low coefficient of friction, typically ranging from 0.05 to 0.2. This makes it one of the slickest materials available.

A unique and critical feature of PTFE is that its static and dynamic friction coefficients are the same. This prevents "stick-slip" behavior, allowing for exceptionally smooth transitions from a standstill to motion.

Nylon has a moderately low coefficient of friction. While it offers good self-lubricating properties, it does not match the elite performance of PTFE.

Load Capacity: A Clear Distinction

There is a significant difference in the amount of compressive load each material can handle in a bearing application.

PTFE can manage significantly higher loads, rated between 750–1,000 psi. This makes it suitable for higher-pressure, slow-moving applications.

Nylon has a much lower load capacity, rated at only 400 psi. It is best suited for lighter-duty applications.

Self-Lubrication and Bearing Life

Both materials are considered self-lubricating, meaning they can operate without external grease or oil, which is ideal for clean environments or inaccessible parts.

Due to its superior properties, PTFE is considered to have a high planned bearing life. Its ability to transfer a thin film to the mating surface maintains low friction over time.

Nylon provides good self-lubrication and is rated for an average bearing life.

Understanding the Trade-offs: The Hidden Weaknesses

A material's strengths often come with corresponding weaknesses. Understanding these trade-offs is crucial for avoiding component failure. The exceptional sliding properties of PTFE are balanced by its relative softness and lack of dimensional stability.

Hardness and Stiffness

PTFE is a relatively soft and flexible material. It has a low hardness value (Rockwell D50-55) and is not very stiff.

While this softness contributes to its good impact resistance, it also means it is more susceptible to scratching and physical damage than harder plastics.

Wear Resistance: The Primary Weakness of PTFE

Despite its low friction, pure PTFE has relatively low wear resistance. In applications with abrasive contaminants or high speeds, it can wear away quickly.

This is the most common trade-off for its slickness. For this reason, PTFE is often enhanced with fillers (like glass, carbon, or bronze) to improve its durability.

The Problem of "Creep" (Cold Flow)

Perhaps the most critical mechanical limitation of PTFE is its tendency to creep. This is a slow, permanent deformation that occurs when the material is subjected to a constant stress, even at room temperature.

For a bushing or thrust washer under a constant load, creep can cause it to lose its precise dimensions over time, leading to a loose fit and eventual failure. This must be a primary consideration during the design phase.

Making the Right Choice for Your Application

Your final decision must be based on the specific demands of your operating environment. There is no single "best" material, only the most appropriate one for the job.

- If your primary focus is minimizing friction and ensuring smooth startup: PTFE is the definitive choice due to its exceptionally low and equal static/dynamic friction coefficients.

- If your application involves high compressive loads at low speeds: PTFE's higher load capacity (750-1000 psi) makes it superior, but you must design the component to account for its tendency to creep.

- If you need a balanced, cost-effective, general-purpose bushing: Nylon often provides a good compromise of moderate strength, decent self-lubrication, and better dimensional stability than unfilled PTFE.

- If high abrasive wear is a significant factor: You should investigate filled grades of PTFE or other polymer families entirely, as pure PTFE will likely fail prematurely.

Ultimately, selecting the right material requires a clear understanding of the application's specific loads, speeds, and environmental conditions.

Summary Table:

| Property | PTFE | Nylon |

|---|---|---|

| Coefficient of Friction | 0.05 - 0.2 (Very Low) | Moderately Low |

| Static/Dynamic Friction | Equal (No Stick-Slip) | Different |

| Load Capacity (PSI) | 750 - 1,000 | 400 |

| Hardness (Rockwell D) | 50-55 (Soft) | Higher |

| Wear Resistance | Low (unless filled) | Good |

| Creep (Cold Flow) | High Tendency | Lower Tendency |

| Bearing Life | High (Planned) | Average |

Need High-Performance PTFE or Nylon Components?

Choosing the right material is critical for the performance and longevity of your bushings, thrust washers, seals, and labware. KINTEK specializes in the precision manufacturing of PTFE and other polymer components for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate these material trade-offs to deliver a solution that meets your exact requirements for friction, load, and environmental conditions. Our expertise includes custom fabrication from prototypes to high-volume orders.

Let's optimize your design. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications