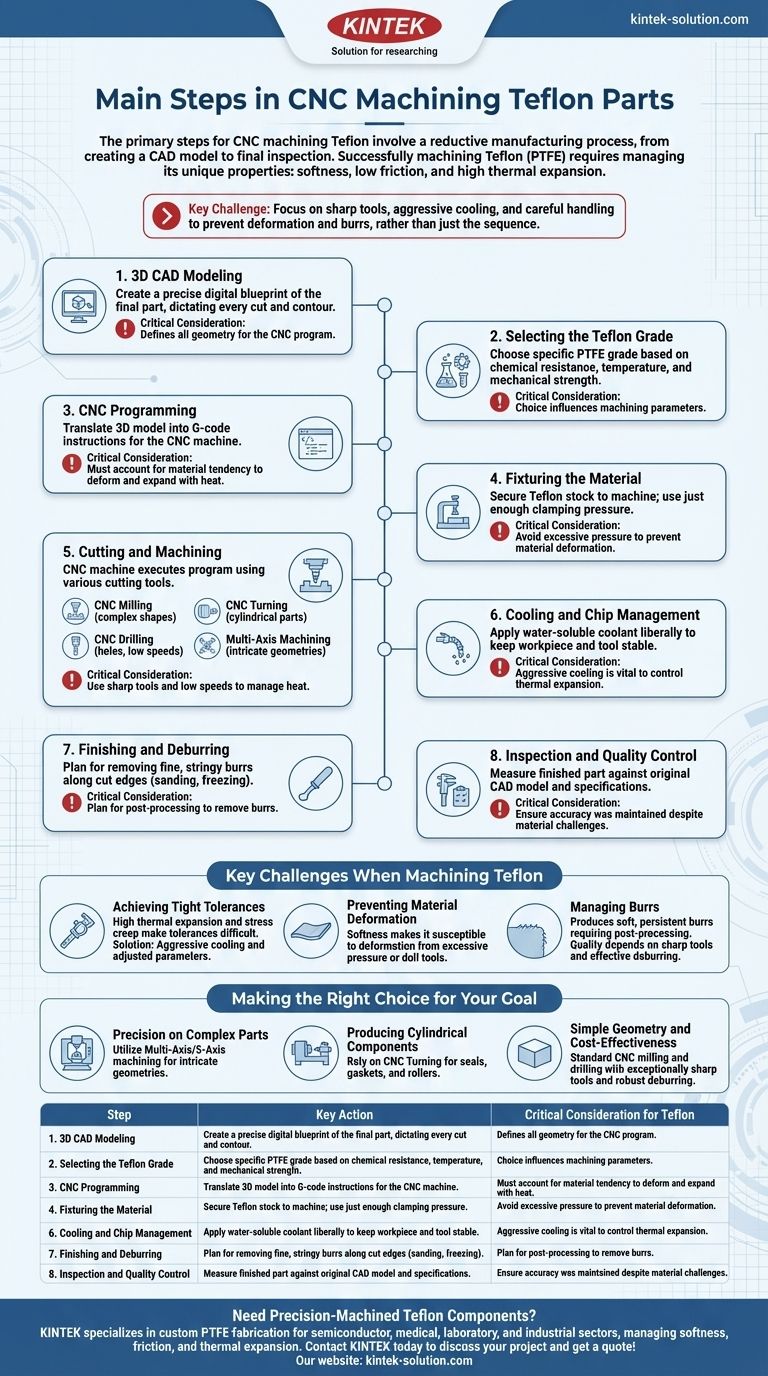

The primary steps for CNC machining Teflon involve creating a CAD model, selecting the material grade, programming the machine, fixturing the workpiece, performing the cutting operations, managing cooling and chip removal, finishing the part, and conducting a final quality inspection. This process is a reductive manufacturing technique where a computer guides cutting tools to remove material and shape the final component.

While the steps appear standard, successfully machining Teflon (PTFE) is less about the sequence and more about managing the material's unique properties. Its softness, low friction, and high thermal expansion demand a specific approach focused on sharp tools, aggressive cooling, and careful handling to prevent deformation and burrs.

The Machining Process: A Detailed Breakdown

Understanding each stage of the process is critical to avoiding common pitfalls associated with this versatile but challenging polymer.

Step 1: 3D CAD Modeling

Before any machining begins, a precise 3D CAD (Computer-Aided Design) model of the final part is created. This digital blueprint dictates every cut, hole, and contour the CNC machine will execute.

Step 2: Selecting the Teflon Grade

Not all Teflon is the same. The specific grade of PTFE is chosen based on the application's requirements for chemical resistance, temperature tolerance, and mechanical strength. This choice can influence machining parameters.

Step 3: CNC Programming

The 3D model is translated into a set of instructions, called G-code, that the CNC machine can understand. For Teflon, the program must account for the material's tendency to deform and expand with heat.

Step 4: Fixturing the Material

The Teflon stock is secured to the CNC machine's work surface. Because Teflon is soft and can be easily compressed, it is crucial to apply just enough clamping pressure to hold the material firmly without deforming it.

Step 5: Cutting and Machining

The CNC machine executes the program, using various cutting tools to shape the part. The specific method depends on the part's geometry.

- CNC Milling: Used for cutting complex shapes, slots, and flat surfaces with high accuracy.

- CNC Turning: Ideal for creating cylindrical or hollow components like seals and bushings.

- CNC Drilling: Used to create holes, but requires low speeds to prevent heat buildup and material melting.

- Multi-Axis Machining: Employed for highly intricate geometries that require the tool to approach the part from multiple angles with extreme precision.

Step 6: Cooling and Chip Management

Teflon's high coefficient of thermal expansion means heat from friction can ruin part accuracy. A liberal application of a water-soluble coolant is essential to keep the workpiece and tool at a stable temperature. Custom tools with better chip clearance are also beneficial.

Step 7: Finishing and Deburring

Teflon is prone to creating fine, stringy burrs along cut edges. A deburring strategy must be planned in advance. Common finishing techniques include careful sanding or even freezing the part to make the burrs brittle and easier to remove.

Step 8: Inspection and Quality Control

The finished part is measured and inspected against the original CAD model and specifications. This ensures that dimensional accuracy was maintained despite the material's challenges.

Key Challenges When Machining Teflon

Ignoring Teflon's unique properties is the most common source of failure. Success requires anticipating and mitigating these specific challenges.

Achieving Tight Tolerances

Teflon’s high rate of thermal expansion and tendency for stress creep make holding tight tolerances difficult. As the material heats up during cutting, it expands, and as it cools, it contracts. This must be managed with aggressive cooling and adjusted machining parameters.

Preventing Material Deformation

The material's softness makes it highly susceptible to deformation. This can happen from excessive clamping pressure during fixturing or from the force of a dull cutting tool pushing against the material instead of cleanly shearing it.

Managing Burrs

Unlike rigid metals that produce clean chips, Teflon produces soft, persistent burrs. This makes post-processing almost mandatory. The quality of the finish is directly related to the sharpness of the cutting tools and the effectiveness of the deburring process.

Making the Right Choice for Your Goal

Your machining strategy should be dictated by the specific requirements of the final component.

- If your primary focus is precision on complex parts: Utilize Multi-Axis/5-Axis machining to achieve intricate geometries with the highest accuracy.

- If your primary focus is producing cylindrical components: Rely on CNC Turning, as it is the most efficient and direct method for parts like seals, gaskets, and rollers.

- If your primary focus is simple geometry and cost-effectiveness: Standard CNC milling and drilling are suitable, but you must prioritize using exceptionally sharp tools and have a robust deburring plan.

Ultimately, mastering Teflon machining comes from respecting the material's unique behavior and adapting your process accordingly.

Summary Table:

| Step | Key Action | Critical Consideration for Teflon |

|---|---|---|

| 1. CAD Modeling | Create a 3D digital blueprint | Defines all geometry for the CNC program |

| 2. Material Selection | Choose the appropriate PTFE grade | Based on chemical, temperature, and strength needs |

| 3. CNC Programming | Generate G-code from the CAD model | Must account for thermal expansion and softness |

| 4. Fixturing | Secure the material stock to the machine | Avoid excessive clamping pressure to prevent deformation |

| 5. Cutting Operations | Mill, turn, or drill the part | Use sharp tools and low speeds to manage heat |

| 6. Cooling & Chip Removal | Apply coolant and clear debris | Aggressive cooling is vital to control thermal expansion |

| 7. Finishing | Deburr and smooth the part | Plan for post-processing to remove stringy burrs |

| 8. Quality Inspection | Verify dimensions and specifications | Ensure accuracy was maintained despite material challenges |

Need Precision-Machined Teflon Components?

Successfully machining PTFE requires specialized expertise to manage its softness, low friction, and high thermal expansion. KINTEK specializes in the custom fabrication of high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine precision production with deep material knowledge to deliver parts that meet your exact specifications, from prototypes to high-volume orders.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support