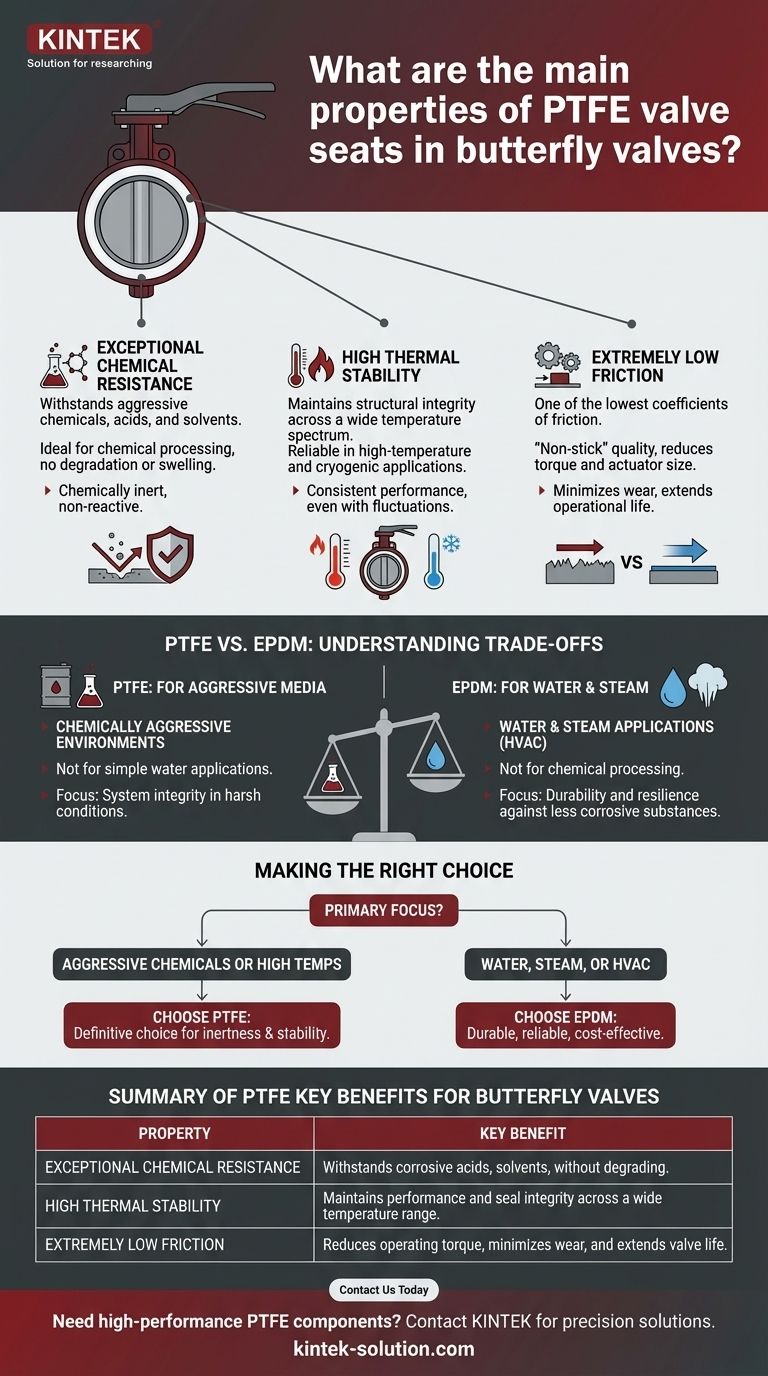

At its core, a PTFE valve seat is defined by three primary properties: exceptional chemical resistance, high thermal stability, and an extremely low coefficient of friction. These characteristics make it a premier choice for demanding industrial applications where the valve must withstand corrosive substances and extreme temperatures without degrading.

The decision to use a Polytetrafluoroethylene (PTFE) seat in a butterfly valve is fundamentally a choice for system integrity in harsh environments. Its unique combination of properties ensures reliability where other materials would quickly fail.

A Breakdown of PTFE's Core Properties

To understand why PTFE is so valued, we must look at how each of its key properties translates into real-world performance within a butterfly valve.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert plastics available. Its non-reactive nature means it will not degrade or swell when exposed to a vast range of aggressive chemicals, acids, and solvents.

This makes PTFE seats the standard choice for industries like chemical processing, where the media flowing through the valve would corrode or destroy lesser materials.

High Thermal Stability

This material maintains its structural integrity and performance characteristics across a wide temperature spectrum. It can operate reliably in both high-temperature and cryogenic applications where many other polymers would become brittle or melt.

This thermal tolerance ensures consistent valve performance and a reliable seal, even when system temperatures fluctuate dramatically.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinct "non-stick" quality.

In a butterfly valve, this low friction reduces the torque required to open and close the valve, which can lower the cost and size of the necessary actuator. It also significantly minimizes wear on the seat and the valve disc, extending the operational life of the entire assembly.

Understanding the Trade-offs: PTFE vs. EPDM

While PTFE is a high-performance material, it isn't the universal solution for every application. Understanding its properties in contrast to a common alternative like EPDM provides critical context for selection.

Application Focus: Chemical vs. Water

The most significant distinction is the intended media. PTFE is built for chemically aggressive environments.

EPDM (Ethylene Propylene Diene Monomer), on the other hand, is the preferred choice for water and steam applications. It excels in systems like HVAC and water treatment, offering excellent durability and resilience against these less corrosive substances.

Performance in Context

Using PTFE in a simple water application might be unnecessary and not cost-effective. Conversely, using an EPDM seat in a chemical processing line would lead to rapid material degradation and catastrophic valve failure.

The choice is not about which material is "better" overall, but which is precisely suited for the specific operational demands to ensure system safety and longevity.

Making the Right Choice for Your Application

Selecting the correct seat material is a critical decision that directly impacts the safety, efficiency, and lifespan of your valve system.

- If your primary focus is handling aggressive chemicals or high temperatures: PTFE is the definitive choice due to its chemical inertness and thermal stability.

- If your primary focus is water, steam, or general HVAC applications: EPDM provides a durable, reliable, and more cost-effective solution specifically suited for these media.

Ultimately, aligning the material's properties with the demands of the application is the key to ensuring optimal performance and long-term reliability.

Summary Table:

| Property | Key Benefit for Butterfly Valves |

|---|---|

| Exceptional Chemical Resistance | Withstands corrosive acids, solvents, and aggressive media without degrading. |

| High Thermal Stability | Maintains performance and seal integrity across a wide temperature range. |

| Extremely Low Friction | Reduces operating torque, minimizes wear, and extends valve life. |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the demanding requirements for chemical resistance, thermal stability, and low friction.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit for your specific needs.

Contact us today to discuss how our PTFE solutions can enhance the reliability and longevity of your systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials