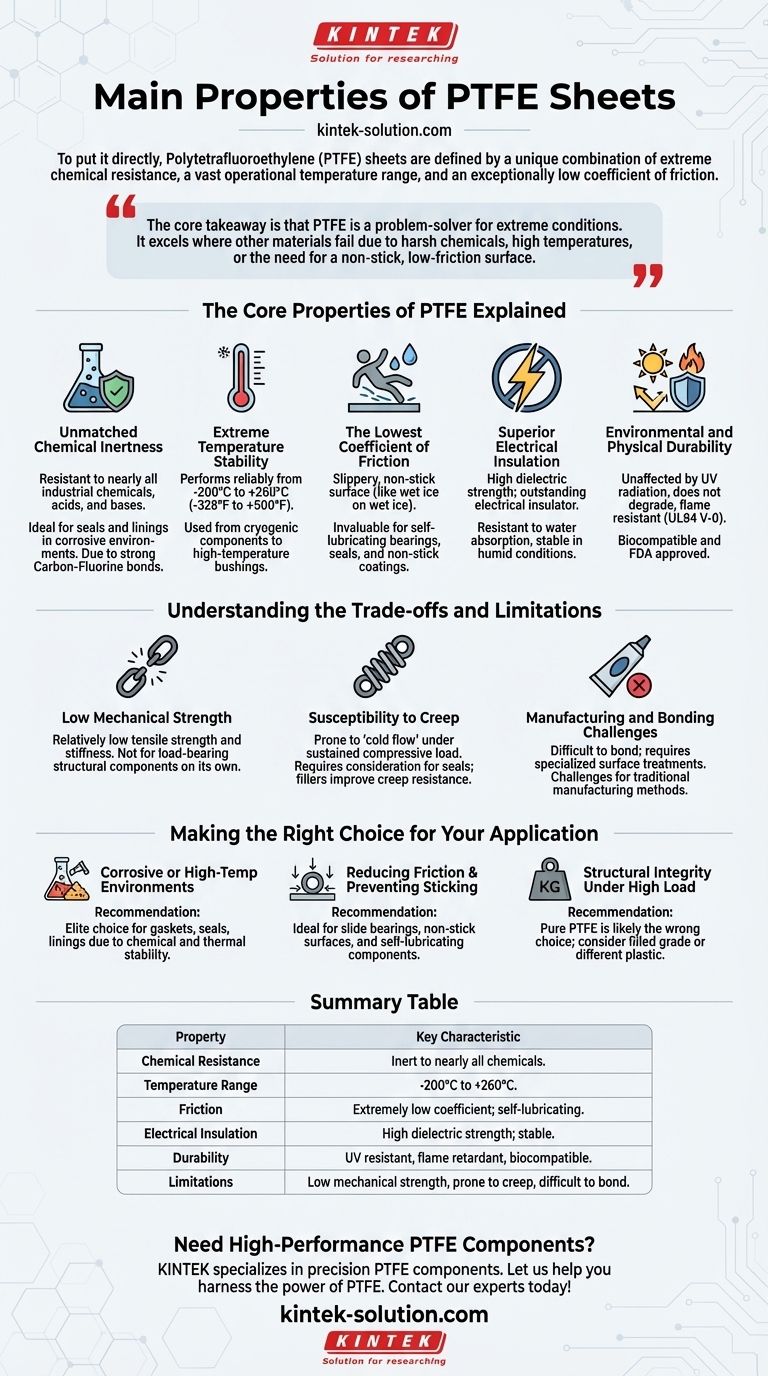

To put it directly, Polytetrafluoroethylene (PTFE) sheets are defined by a unique combination of extreme chemical resistance, a vast operational temperature range, and an exceptionally low coefficient of friction. These properties stem from its strong carbon-fluorine bonds, making it one of the most versatile and reliable engineering plastics for demanding environments.

The core takeaway is that PTFE is a problem-solver for extreme conditions. It excels where other materials fail due to harsh chemicals, high temperatures, or the need for a non-stick, low-friction surface. However, its effectiveness is tied to understanding its mechanical limitations.

The Core Properties of PTFE Explained

PTFE's value is not in a single attribute but in the powerful synergy of its characteristics. Understanding each property allows for its proper application in engineering and design.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and bases. This makes it an ideal material for seals, gaskets, and linings in corrosive environments.

This exceptional resistance is due to the high concentration of fluorine, which creates a stable and non-reactive molecular shield around the carbon backbone of the polymer.

Extreme Temperature Stability

PTFE performs reliably across an exceptionally wide thermal window, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in applications ranging from cryogenic components to high-temperature bushings and insulators without degrading or losing its core properties.

The Lowest Coefficient of Friction

Among all known solid materials, PTFE has one of the lowest coefficients of friction. This results in a slippery, non-stick surface that is often compared to wet ice on wet ice.

This property is invaluable for creating self-lubricating bearings, low-friction seals, and non-stick coatings for industrial processes.

Superior Electrical Insulation

PTFE possesses very high dielectric strength, making it an outstanding electrical insulator. It is widely used for high-frequency applications, cable insulation, and circuit boards.

Its resistance to water absorption (less than 0.01%) ensures its insulating properties remain stable even in humid conditions.

Environmental and Physical Durability

Beyond its primary attributes, PTFE is also highly resistant to environmental factors. It is unaffected by UV radiation, does not degrade with age, and is inherently flame resistant (UL94 V-0 rated).

Furthermore, its biocompatibility and FDA approval make it suitable for use in medical devices and food processing equipment.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging PTFE's limitations is critical for successful implementation and avoiding application failures.

Low Mechanical Strength

Compared to other engineering plastics, PTFE has relatively low tensile strength and stiffness. It is a soft material and not intended for load-bearing structural components on its own.

Susceptibility to Creep

Under sustained compressive load, especially at elevated temperatures, PTFE is prone to creep, or cold flow. This means it will slowly deform over time.

This is a critical design consideration for seals and gaskets, where maintaining constant pressure is essential. Fillers like glass fiber or carbon are often added to PTFE to improve its creep resistance.

Manufacturing and Bonding Challenges

PTFE's non-stick nature makes it very difficult to bond to other materials using conventional adhesives. This often requires specialized surface treatments like chemical etching.

Its unique properties also present challenges for traditional manufacturing methods like injection molding, requiring specialized processing techniques.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its strengths with your primary engineering goal.

- If your primary focus is performance in corrosive or high-temperature environments: PTFE is an elite choice for gaskets, seals, and linings due to its chemical and thermal stability.

- If your primary focus is reducing friction and preventing sticking: PTFE is the ideal material for slide bearings, non-stick surfaces, and self-lubricating components.

- If your primary focus is structural integrity under high mechanical load: Pure PTFE is likely the wrong choice; consider a filled grade of PTFE or a different engineering plastic altogether.

Ultimately, choosing PTFE is a decision to prioritize chemical, thermal, and frictional performance above raw mechanical strength.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Inert to nearly all industrial chemicals, acids, and bases. |

| Temperature Range | Stable from -200°C to +260°C (-328°F to +500°F). |

| Friction | Extremely low coefficient of friction; self-lubricating. |

| Electrical Insulation | High dielectric strength; stable in humid conditions. |

| Durability | UV resistant, flame retardant (UL94 V-0), and biocompatible. |

| Limitations | Low mechanical strength, prone to creep under load, difficult to bond. |

Need High-Performance PTFE Components for Your Project?

KINTEK specializes in the precision manufacturing of PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We leverage PTFE's exceptional properties to solve your most demanding challenges, offering custom fabrication from prototypes to high-volume orders.

Let us help you harness the power of PTFE. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the special considerations for CNC machining PTFE? Master the Art of Precision Machining

- How does the temperature resistance of PTFE O-rings compare to other materials? Superior Performance from -250°C to +260°C

- How does PTFE compare to other elastomers in temperature resilience? Unmatched Performance from -200°C to 260°C

- What are the load-bearing capabilities of PTFE sheets? A Guide to Its Unique Strengths and Limitations

- What are the common applications of Teflon bushings in industrial machinery? Solve Friction, Corrosion, and Contamination Problems

- Where are thick PTFE washers (2mm – 4mm) typically used? For High-Pressure Sealing & Electrical Insulation

- How does a Teflon sheet protect materials during heat press applications? Prevent Scorching & Smudging for Professional Results

- What advantages do ePTFE gaskets have over conventional rubber and plastic seals? Superior Performance in Extreme Environments