The primary features of a PTFE bellow mechanical seal are its near-universal chemical resistance, an exceptionally low coefficient of friction, and a flexible bellow design that compensates for shaft movement. These characteristics are derived directly from its core material, Polytetrafluoroethylene (PTFE), making it a specialized solution for highly demanding environments.

A PTFE bellow seal is not a general-purpose component. It is an engineered solution designed specifically for low-pressure applications involving highly corrosive chemicals or stringent sanitary requirements where standard elastomer or metal seals would quickly fail.

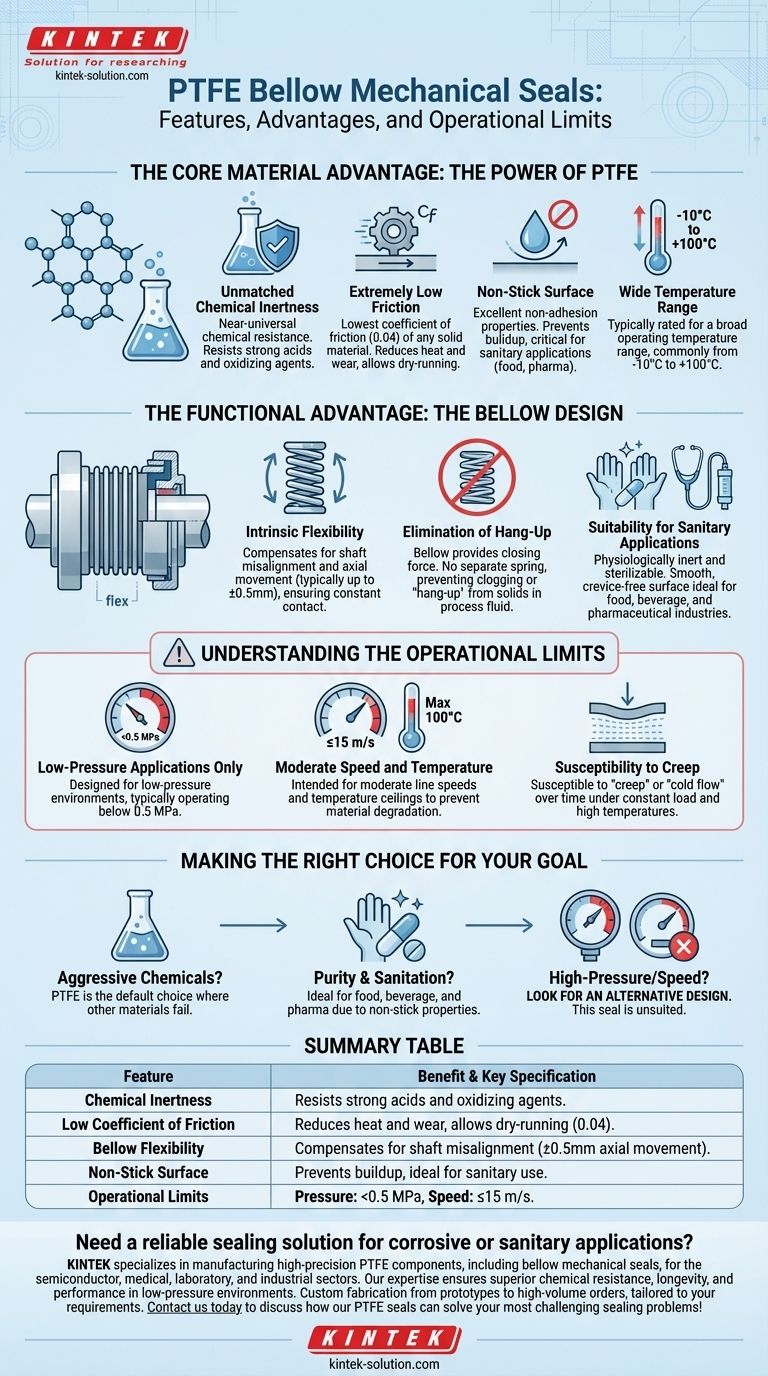

The Core Material Advantage: The Power of PTFE

The defining characteristics of the seal come directly from the unique properties of Polytetrafluoroethylene.

Unmatched Chemical Inertness

Often called the "king of plastic," PTFE is one of the most corrosion-resistant materials available.

It can operate continuously in aggressive media, including strong acids and strong oxidizing agents, that would destroy other materials.

Extremely Low Friction

PTFE has the lowest coefficient of friction of any solid material, measured at just 0.04.

This inherent lubricity reduces operational heat and wear on the seal faces, extending service life and improving efficiency. It allows the seal to function effectively even in oil-free or dry-running scenarios.

Non-Stick Surface

The material's surface has excellent non-adhesion properties, preventing media from sticking to or building up on the seal components.

This is critical in sanitary applications like food processing and pharmaceuticals, where residue buildup is unacceptable. It also prevents the clogging that can cause other seal types to fail.

Wide Temperature Range

While specific designs vary, PTFE bellow seals are typically rated for a broad operating temperature range, commonly from -10°C to +100°C.

The Functional Advantage: The Bellow Design

The bellow construction leverages PTFE's properties to create a superior dynamic seal.

Intrinsic Flexibility

The bellow design allows the seal to compensate for shaft misalignment and axial movement, typically up to ±0.5mm.

This flexibility ensures the seal faces remain in constant contact, maintaining a reliable seal even with minor equipment imperfections or vibration.

Elimination of Hang-Up

Unlike seals that rely on a separate spring for tension, the bellow itself provides the necessary closing force.

This single-unit design eliminates the risk of clogging or "hang-up," where solids in the process fluid could jam a traditional spring mechanism and cause seal failure.

Suitability for Sanitary Applications

Because PTFE is physiologically inert and can be sterilized, it is an ideal choice for the food, beverage, and pharmaceutical industries.

The smooth, crevice-free surface of the bellow design further enhances its suitability for these hygienic processes.

Understanding the Operational Limits

To use a PTFE bellow seal effectively, it is critical to understand its specific operational trade-offs. It is a specialized tool, not a universal one.

Low-Pressure Applications Only

This is the most critical limitation. PTFE bellow seals are designed for low-pressure environments, typically operating below 0.5 MPa. Their material properties are not suited for high-pressure sealing duties.

Moderate Speed and Temperature

The seal is intended for moderate line speeds, generally up to 15 m/s, and its temperature ceiling of around 100°C must be respected to prevent material degradation.

Susceptibility to Creep

PTFE, like many polymers, can be susceptible to "creep" or "cold flow" over time, especially under constant load and at higher temperatures. Proper design and staying within specified operational limits are essential to mitigate this effect.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching its features to your primary challenge.

- If your primary focus is handling aggressive chemicals: The near-total chemical inertness of PTFE makes this seal the default choice where other materials fail.

- If your primary focus is purity and sanitation: The non-stick, physiologically inert properties and crevice-free design are ideal for food, beverage, and pharmaceutical applications.

- If your primary focus is high-pressure or high-speed operation: You must look for an alternative design, as this seal is fundamentally unsuited for those demanding conditions.

Choosing the right seal is about understanding the problem, and for extreme corrosion at low pressure, the PTFE bellow seal is often the perfect solution.

Summary Table:

| Feature | Benefit | Key Specification |

|---|---|---|

| Chemical Inertness | Resists strong acids and oxidizing agents | Near-universal chemical resistance |

| Low Coefficient of Friction | Reduces heat and wear, allows dry-running | 0.04 (extremely low) |

| Bellow Flexibility | Compensates for shaft misalignment | ±0.5mm axial movement |

| Non-Stick Surface | Prevents buildup, ideal for sanitary use | Excellent non-adhesion |

| Operational Limits | Best for specific, demanding conditions | Pressure: <0.5 MPa, Speed: ≤15 m/s |

Need a reliable sealing solution for corrosive or sanitary applications?

KINTEK specializes in manufacturing high-precision PTFE components, including bellow mechanical seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal that offers superior chemical resistance, longevity, and performance in low-pressure environments.

We provide custom fabrication from prototypes to high-volume orders, tailored to your specific requirements.

Contact us today to discuss how our PTFE seals can solve your most challenging sealing problems!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries