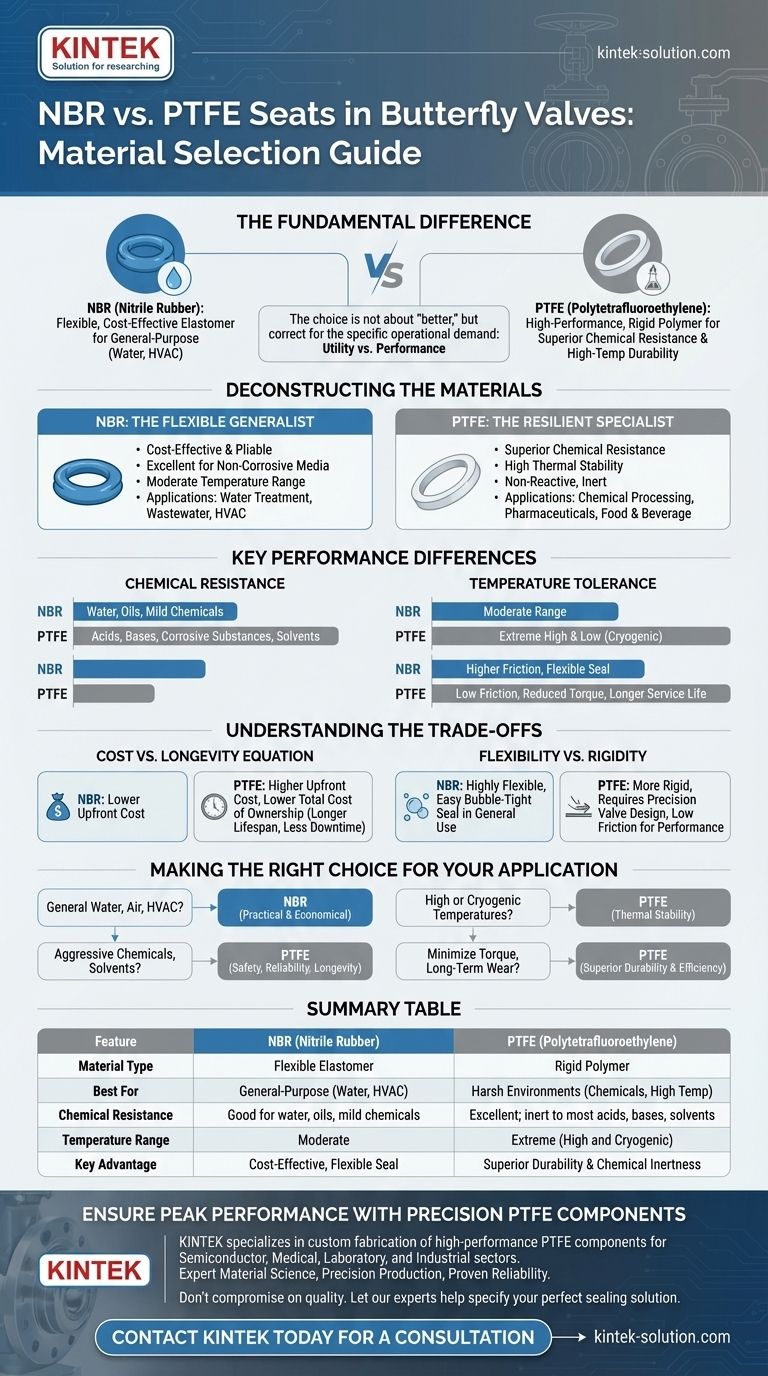

The fundamental difference is that NBR (Nitrile Rubber) seats are flexible, cost-effective elastomers designed for general-purpose applications like water and HVAC, while PTFE (Polytetrafluoroethylene) seats are high-performance, rigid polymers engineered for superior chemical resistance and high-temperature durability in demanding industrial environments.

The choice between NBR and PTFE is not about which is "better," but which is correct for the specific operational demand. It is a classic engineering trade-off between the broad utility and lower cost of NBR and the specialized, robust performance of PTFE.

Deconstructing the Materials: NBR vs. PTFE

Understanding the core properties of each material reveals why they are suited for entirely different operational contexts.

NBR (Nitrile Rubber): The Flexible Generalist

NBR is an elastomer known for its flexibility and ability to create a tight seal in standard service conditions.

Its primary characteristics are cost-effectiveness and pliability. This makes it an excellent choice for applications where the media is non-corrosive and temperatures are moderate.

Common applications for NBR seats include water treatment, wastewater, and HVAC systems where a reliable seal is needed without exposure to aggressive chemicals.

PTFE (Polytetrafluoroethylene): The Resilient Specialist

PTFE is a fluoropolymer recognized for its exceptional resilience in harsh conditions. It is fundamentally different from a flexible rubber.

Its key properties are superior chemical resistance and high thermal stability. PTFE is non-reactive, making it nearly inert to most chemicals and solvents.

This material excels in demanding environments such as chemical processing, pharmaceuticals, and food and beverage, where media incompatibility can lead to catastrophic failure.

Key Performance Differences

The material properties directly translate into distinct performance advantages and limitations in a live system.

Chemical Resistance

PTFE offers a far wider range of chemical compatibility. Its non-reactive nature ensures the integrity of the valve seat when exposed to acids, bases, and other corrosive substances.

NBR is suitable for water, oils, and some mild chemicals but will degrade when exposed to more aggressive media.

Temperature Tolerance

PTFE seats can withstand extreme temperatures, both high and low, without losing their structural integrity. This high thermal stability is critical for processes involving steam or other high-temperature fluids.

NBR seats operate within a more moderate temperature range and can become brittle or lose their sealing capability at temperature extremes.

Durability and Friction

The low coefficient of friction of PTFE is a significant advantage. It reduces the torque required to operate the valve and minimizes wear and tear on the seat, contributing to a longer service life.

NBR, being a rubber, has higher friction. However, its flexibility allows it to seal effectively against the valve disc with minimal force in low-pressure applications.

Understanding the Trade-offs

Selecting a valve seat requires a clear understanding of the compromises between cost, performance, and operational lifespan.

The Cost vs. Longevity Equation

NBR is significantly more cost-effective on an initial purchase basis. For standard utility services, it provides excellent performance for its price.

PTFE has a higher upfront cost but delivers a longer lifespan and greater reliability in harsh environments. This often results in a lower total cost of ownership by reducing downtime and replacement frequency.

Flexibility vs. Rigidity

The flexibility of NBR allows it to easily form a bubble-tight seal, which is highly effective in general-purpose butterfly valves.

PTFE is a more rigid material. While this rigidity contributes to its durability, it requires a well-designed valve body and disc to ensure a perfect seal. Its low-friction surface is what ensures sealing performance and prevents galling.

Making the Right Choice for Your Application

Your decision must be driven by the specific demands of your system.

- If your primary focus is general water, air, or HVAC systems: NBR is the most practical and economical choice, providing a reliable seal in moderate conditions.

- If your application involves aggressive chemicals, solvents, or corrosive media: PTFE is the only suitable option to ensure safety, reliability, and system longevity.

- If your system operates at high or cryogenic temperatures: PTFE's exceptional thermal stability is required to prevent material failure.

- If your priority is minimizing valve torque and long-term wear: PTFE's low-friction surface offers superior durability and operational efficiency.

Ultimately, matching the seat material to the operational media and temperature is the most critical factor in ensuring the performance and safety of your system.

Summary Table:

| Feature | NBR (Nitrile Rubber) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Material Type | Flexible Elastomer | Rigid Polymer |

| Best For | General-Purpose (Water, HVAC) | Harsh Environments (Chemicals, High Temp) |

| Chemical Resistance | Good for water, oils, mild chemicals | Excellent; inert to most acids, bases, solvents |

| Temperature Range | Moderate | Extreme (High and Cryogenic) |

| Key Advantage | Cost-Effective, Flexible Seal | Superior Durability & Chemical Inertness |

Ensure Peak Performance with Precision PTFE Components

Selecting the correct valve seat is critical for system integrity, safety, and cost-efficiency. For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, the superior properties of PTFE are non-negotiable.

KINTEK specializes in the custom fabrication of high-performance PTFE components, including seals, liners, and labware. We deliver the precision and durability your critical processes require.

Why partner with KINTEK?

- Expert Material Science: We understand the demands of specialized industries.

- Precision Production: From prototypes to high-volume orders, we ensure every component meets exact specifications.

- Proven Reliability: Our components are engineered for longevity in the most challenging environments.

Don't compromise on quality. Let our experts help you specify the perfect sealing solution for your application.

Contact KINTEK today for a consultation to discuss your custom PTFE needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs