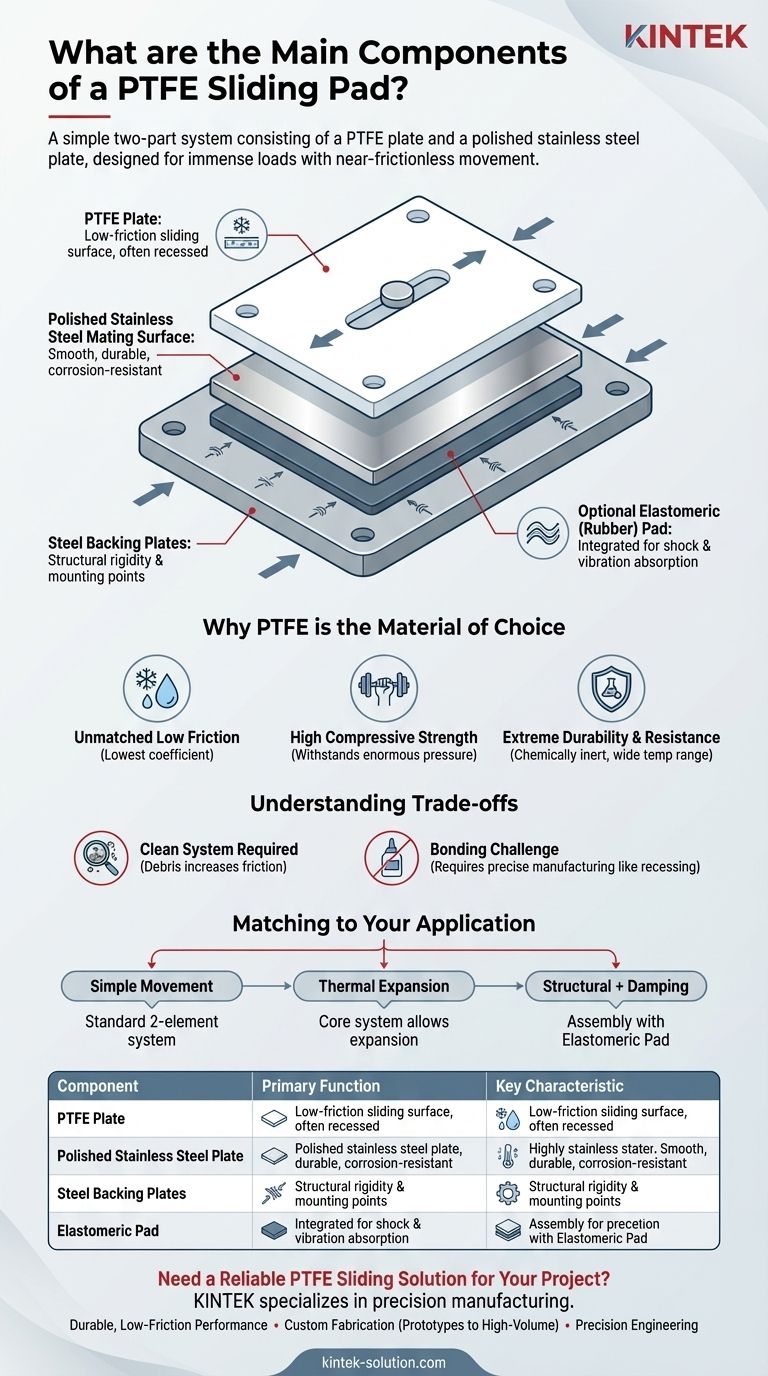

At its core, a PTFE sliding pad is a simple two-part system. It consists of a Polytetrafluoroethylene (PTFE) plate designed to slide against a highly polished stainless steel plate. These two primary components are almost always bonded or welded to rigid backing plates, creating a complete upper and lower assembly capable of supporting immense loads with minimal friction.

The fundamental purpose of a PTFE sliding pad is to leverage the unique, near-frictionless interaction between PTFE and polished stainless steel. This allows for controlled, maintenance-free movement, expansion, or rotation in heavy structures.

The Core Functional Components

While a complete bearing assembly can include many parts like anchor bolts and dust covers, the sliding function itself relies on a few key elements working in concert.

The PTFE Plate

This is the heart of the bearing's low-friction capability. The PTFE is typically a thin sheet bonded into a recess within a steel backing plate.

This recessed "pocket" design is critical because PTFE is notoriously difficult to bond. Securing it mechanically ensures it remains in place under high pressure and movement.

The Stainless Steel Mating Surface

The PTFE slides against a polished stainless steel plate. The quality of this surface is just as important as the PTFE itself.

It must be extremely smooth to achieve the lowest possible coefficient of friction. Stainless steel is used for its durability and, most importantly, its high resistance to corrosion, ensuring the surface remains smooth over the life of the bearing.

The Steel Backing Plates

Neither the PTFE nor the thin stainless steel layer provides significant structural rigidity on its own. They are attached to thicker backing plates, typically made of mild steel.

These backing plates provide the necessary strength, keep the functional layers perfectly flat, and serve as the mounting point for welding or bolting the bearing to the larger structure.

The Optional Elastomeric (Rubber) Pad

In applications that require shock or vibration absorption, such as bridges or large HVAC systems, a rubber bearing pad is often integrated into the assembly.

The PTFE pad is bonded to this rubber layer, which absorbs vibrations and provides a buffering effect, reducing noise and stress on the structure.

Why PTFE is the Material of Choice

The selection of PTFE is not arbitrary; its unique molecular properties make it the ideal material for high-load, low-friction applications.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material—even lower than wet ice on wet ice. This allows massive structures to slide effortlessly.

High Compressive Strength

Despite its slippery nature, PTFE can withstand enormous pressures without being crushed or deformed. This is essential for supporting the weight of buildings, bridges, and heavy industrial equipment.

Extreme Durability and Resistance

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals, solvents, and acids. It is also unaffected by weather, UV light, and a vast temperature range (from -196°C to +260°C), ensuring long-term performance in harsh environments.

Understanding the Trade-offs

While highly effective, the design and implementation of PTFE sliding pads require an understanding of their limitations.

The Importance of a Clean System

The low-friction property depends on the direct contact between clean PTFE and polished stainless steel. The introduction of dirt, grit, or debris can dramatically increase friction and cause abrasive wear.

The Bonding Challenge

As mentioned, PTFE's chemical inertness makes it very difficult to glue to other materials. This necessitates precise manufacturing techniques, like recessing the PTFE into a pocket, to ensure a reliable and permanent mechanical bond.

Simple Pads vs. Complex Assemblies

The basic two-plate system is just the starting point. For demanding applications like bridge bearings, the core components are built into a much larger assembly that may include guide plates to control the direction of movement, anchor bolts for mounting, and dust covers for protection.

Matching the Components to Your Application

The specific configuration of a PTFE sliding pad should be dictated by the engineering goal.

- If your primary focus is simple rotational or linear movement: A standard two-element system (PTFE on a steel backer plate and stainless steel on its own backer plate) is the most direct solution.

- If your primary focus is accommodating thermal expansion: The core two-element system is ideal, allowing structures like pipelines or long-span roofs to expand and contract without building up stress.

- If your primary focus is structural support with vibration damping: Specifying an assembly that integrates an elastomeric (rubber) pad is critical for absorbing shock and reducing noise transmission.

By understanding how these core components function together, you can ensure your project benefits from a durable, predictable, and maintenance-free sliding system.

Summary Table:

| Component | Primary Function | Key Characteristic |

|---|---|---|

| PTFE Plate | Provides low-friction sliding surface | Extremely low coefficient of friction, high compressive strength |

| Polished Stainless Steel Plate | Mating surface for the PTFE | Highly smooth, durable, and corrosion-resistant |

| Steel Backing Plates | Provides structural rigidity and mounting points | Thick, strong, keeps functional layers flat |

| Elastomeric Pad (Optional) | Absorbs shock and vibration | Integrated for applications requiring damping |

Need a Reliable PTFE Sliding Solution for Your Project?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom sliding pads and bearings. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your application benefits from:

- Durable, Low-Friction Performance: Leverage the unmatched properties of PTFE for maintenance-free movement.

- Custom Fabrication: We tailor components from prototypes to high-volume orders to meet your exact specifications, including complex assemblies with integrated features.

- Precision Engineering: Our components are built for reliability, supporting immense loads and performing in harsh environments.

Let us provide the critical components your project needs. Contact KINTEK today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability