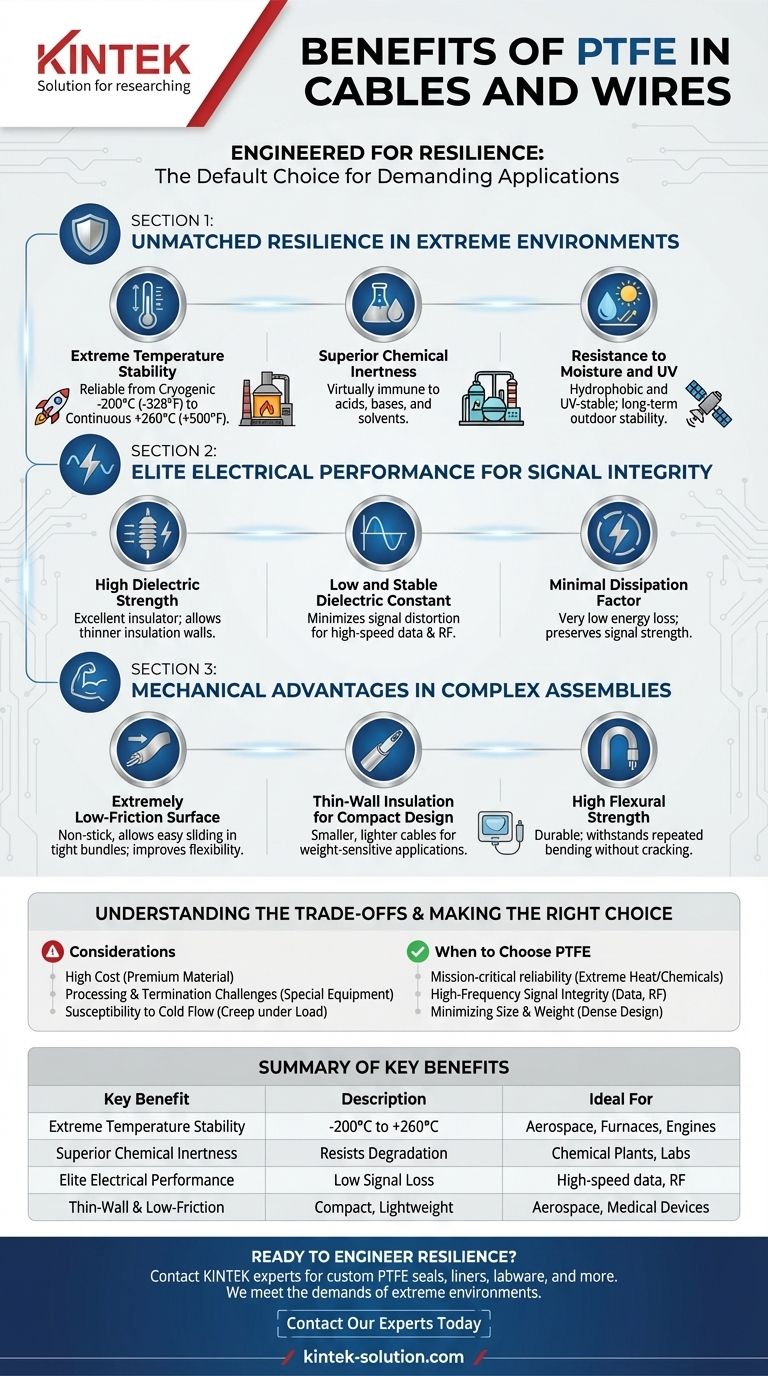

In short, the primary benefits of using Polytetrafluoroethylene (PTFE) in cables and wires are its exceptional resistance to extreme temperatures, chemicals, and fire. Its superior electrical properties ensure high signal integrity, while its thin, low-friction nature allows for the creation of compact, lightweight, and flexible cable assemblies ideal for demanding applications.

The decision to use PTFE is not merely about choosing a durable material; it's about engineering for resilience. PTFE is the default choice for applications where performance cannot be compromised by harsh environments, making it essential for mission-critical systems in aerospace, industrial, and medical fields.

Unmatched Resilience in Extreme Environments

PTFE's reputation is built on its ability to function flawlessly where other materials fail. This resilience stems from its unique molecular structure, providing a trifecta of environmental resistances.

Extreme Temperature Stability

PTFE has the widest operational temperature range of any polymer, performing reliably from cryogenic lows of -200°C (-328°F) up to continuous highs of +260°C (+500°F). This makes it indispensable for applications involving industrial furnaces, engine compartments, and aerospace systems that experience drastic temperature shifts.

Superior Chemical Inertness

This material is virtually immune to degradation from aggressive chemicals, acids, bases, and solvents. Wires insulated with PTFE can be routed through chemically hostile environments, such as chemical processing plants or laboratories, without risk of insulation failure.

Resistance to Moisture and UV

PTFE is hydrophobic, meaning it actively repels water and is suitable for hot, wet environments. The expanded form (ePTFE) is also highly resistant to UV radiation, ensuring long-term stability in outdoor applications where other plastics would become brittle.

Elite Electrical Performance for Signal Integrity

For any advanced electronic system, preserving the integrity of the electrical signal is paramount. PTFE's electrical properties are nearly ideal for this purpose, especially in high-frequency applications.

High Dielectric Strength

PTFE is an outstanding electrical insulator, meaning it effectively prevents the leakage of electrical current. This high dielectric strength allows for thinner insulation walls without sacrificing safety or performance.

Low and Stable Dielectric Constant

PTFE has an extremely low dielectric constant that remains stable across a wide range of frequencies and temperatures. This property is critical for high-speed data and RF cables, as it minimizes signal distortion and energy loss, ensuring clean, fast, and reliable data transmission.

Minimal Dissipation Factor

The material's low dissipation factor means that very little electrical energy is lost as heat when an alternating current is applied. This efficiency is crucial for preserving signal strength in communication systems and high-power applications.

Mechanical Advantages in Complex Assemblies

Beyond its environmental and electrical benefits, PTFE's physical characteristics provide tangible advantages in the design and installation of complex wire harnesses.

Extremely Low-Friction Surface

Often cited as the most slippery solid material in existence, PTFE has a non-stick surface. This allows individual wires to slide easily against each other within a cable bundle, drastically improving flexibility and simplifying installation in tight conduits.

Thin-Wall Insulation for Compact Design

Because of its excellent dielectric strength and durability, PTFE insulation can be applied in very thin layers. This directly translates to smaller, lighter cables, a critical requirement in weight-sensitive applications like aerospace, satellites, and medical devices.

High Flexural Strength

Despite its flexibility, PTFE is a durable material that withstands repeated bending and flexing without cracking or fatigue. This ensures mechanical reliability in dynamic applications where cables are subject to constant movement.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations and considerations associated with using a premium material like PTFE.

The High Cost Factor

PTFE is a premium performance polymer, and its cost is significantly higher than that of more common insulators like PVC or polyethylene. Its use is typically justified only when its unique properties are a strict requirement.

Processing and Termination Challenges

Manufacturing cables with PTFE requires specialized high-temperature extrusion equipment. Furthermore, its slippery and tough nature can make it more difficult to strip for termination, often requiring thermal or precision blade strippers.

Susceptibility to Cold Flow

Under sustained, high-pressure mechanical loads, PTFE can exhibit "cold flow," or creep. This means the material can slowly deform over time. Engineers must account for this by designing clamping and connector systems that apply pressure evenly without creating pinch points.

Making the Right Choice for Your Application

Selecting the right insulation is a balance of performance, environment, and cost. Use these guidelines to determine if PTFE is the correct choice for your project.

- If your primary focus is mission-critical reliability in extreme heat or chemical exposure: PTFE's unparalleled thermal and chemical stability makes it the definitive choice.

- If your primary focus is high-frequency signal integrity: PTFE's low and stable dielectric constant is essential for high-speed data, RF, and microwave applications.

- If your primary focus is minimizing size and weight for a dense design: PTFE's thin-wall insulation capability enables the most compact and lightweight cable assemblies possible.

- If your primary focus is cost-effectiveness for a standard environment: A more conventional insulator like PVC or FEP likely offers a more practical and economical solution.

By understanding these core properties and trade-offs, you can confidently specify the right material to ensure your system's long-term performance and reliability.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Extreme Temperature Stability | Operates reliably from -200°C to +260°C. | Aerospace, industrial furnaces, engine compartments. |

| Superior Chemical Inertness | Resists degradation from acids, bases, and solvents. | Chemical processing plants, laboratories. |

| Elite Electrical Performance | Low, stable dielectric constant for minimal signal loss. | High-speed data, RF, and microwave cables. |

| Thin-Wall & Low-Friction | Enables compact, lightweight, and flexible cable designs. | Weight-sensitive applications (aerospace, medical devices). |

Ready to engineer resilience into your next project with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components meet the demanding requirements of extreme environments and mission-critical systems.

Contact our experts today to discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications