The primary advantages of Teflon Bellow Mechanical Seals are their exceptional chemical resistance, wide operating temperature range, and robust design that leads to a longer service life. These seals are specifically engineered to perform reliably in aggressive industrial environments where traditional sealing solutions would quickly fail, ultimately reducing long-term maintenance costs and increasing equipment uptime.

The decision to use a Teflon Bellow Mechanical Seal is a strategic investment in reliability. While potentially carrying a higher initial cost, its superior resilience against harsh chemicals and extreme temperatures provides a lower total cost of ownership by drastically minimizing downtime and frequent replacements.

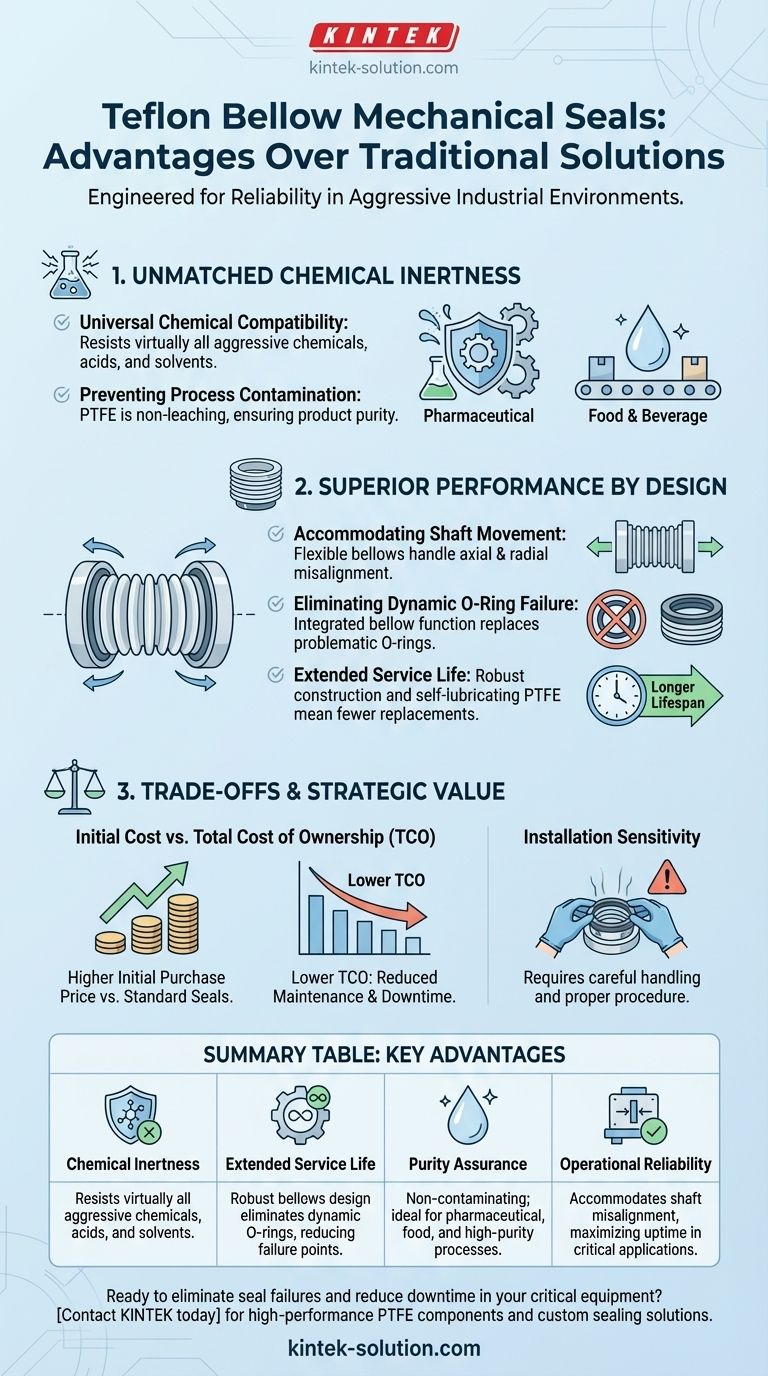

The Core Advantage: Unmatched Chemical Inertness

The defining feature of these seals comes from their primary material of construction: Polytetrafluoroethylene (PTFE), commonly known as Teflon. This material's properties are the main reason for its selection in demanding applications.

Universal Chemical Compatibility

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. Unlike traditional elastomeric seals (like rubber O-rings) which can swell, degrade, or dissolve when exposed to aggressive media, a Teflon bellow maintains its integrity.

This eliminates a common and costly failure mode in chemical processing, petrochemical, and pharmaceutical industries.

Preventing Process Contamination

Because PTFE is so inert, it does not leach substances into the process fluid. This is a non-negotiable requirement in high-purity applications such as food and beverage production, pharmaceuticals, and electronics manufacturing, where product purity is paramount.

Superior Performance by Design

Beyond material choice, the "bellows" design itself provides distinct mechanical advantages over simpler seal arrangements. It is engineered to compensate for the realities of rotating equipment.

Accommodating Shaft Movement

The flexible bellow is designed to handle both axial shaft movement and radial misalignment without compromising the seal. This ability to flex and adapt ensures the seal faces remain in constant, optimal contact, preventing leaks even under imperfect operating conditions.

Eliminating Dynamic O-Ring Failure

In many traditional "pusher" type mechanical seals, a secondary elastomeric O-ring must slide along the shaft to compensate for wear. This O-ring is a frequent point of failure, as it can hang up, fret, or degrade.

The Teflon bellow design integrates this function into the bellow itself, completely eliminating the dynamic O-ring and one of the most common causes of seal failure.

Extended Service Life

The combination of a highly durable, self-lubricating material (PTFE) and a robust bellows design results in a significantly longer service life. Studies have shown that components using PTFE seals can last several times longer than those with traditional materials, directly contributing to increased equipment reliability.

Understanding the Trade-offs

No engineering solution is without its context. Acknowledging the trade-offs is key to making an informed decision.

Initial Cost vs. Total Cost of Ownership

The most significant consideration is the initial purchase price. Teflon Bellow Seals are more expensive than standard elastomeric or component seals.

However, this higher upfront cost is often justified by the total cost of ownership. When you factor in reduced maintenance, less production downtime, and fewer seal replacements over the equipment's lifespan, the Teflon bellow seal frequently proves to be the more cost-effective solution for challenging applications.

Installation Sensitivity

While extremely durable in operation, PTFE is a less forgiving material than a flexible elastomer during installation. It is more rigid and requires careful handling to avoid scratching or gauging the sealing surfaces, which could compromise performance. Proper training and procedure are essential.

Making the Right Choice for Your Application

Your decision should be based on a clear-eyed assessment of your operating environment and long-term goals.

- If your primary focus is handling aggressive media: A Teflon Bellow Seal is the definitive choice for pumping corrosive chemicals, acids, or solvents where other materials would rapidly fail.

- If your primary focus is ensuring product purity: The inert nature of PTFE makes it an essential requirement for pharmaceutical, food-grade, or other high-purity processes.

- If your primary focus is maximizing uptime and reliability: In critical applications where seal failure leads to costly downtime, the extended service life and robust design of a Teflon Bellow Seal provide the best long-term value.

Ultimately, choosing a Teflon Bellow Mechanical Seal is an investment in operational stability for your most demanding applications.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists virtually all aggressive chemicals, acids, and solvents. |

| Extended Service Life | Robust bellows design eliminates dynamic O-rings, reducing failure points. |

| Purity Assurance | Non-contaminating; ideal for pharmaceutical, food, and high-purity processes. |

| Operational Reliability | Accommodates shaft misalignment, maximizing uptime in critical applications. |

Ready to eliminate seal failures and reduce downtime in your critical equipment?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom Teflon Bellow Mechanical Seals. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our seals are engineered for superior chemical resistance and long-term reliability in your most demanding environments.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific application.

Contact KINTEK today to discuss your sealing challenges and discover how our PTFE solutions can enhance your operational stability and reduce your total cost of ownership.

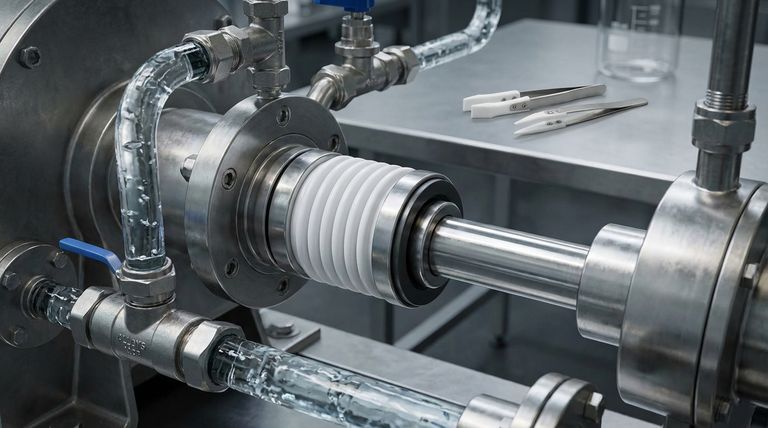

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts