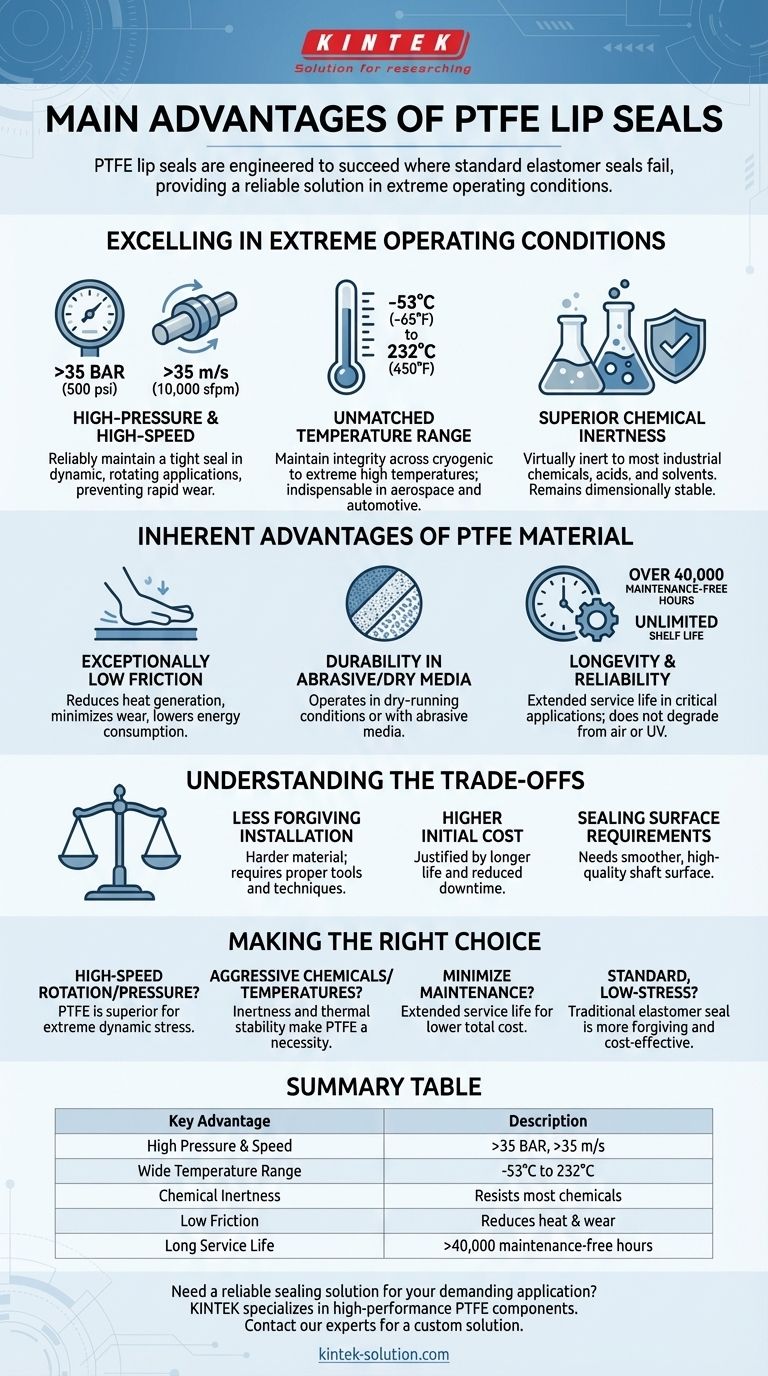

PTFE lip seals are engineered to succeed where standard elastomer seals fail. They provide a reliable sealing solution in applications defined by extreme operating conditions, including high pressure, high rotational speeds, a wide temperature range, and aggressive chemical environments.

The core advantage is not that PTFE seals are universally better, but that they are a specialized solution for high-performance applications. They solve sealing challenges that are simply beyond the physical and chemical limits of traditional rubber-based seals.

Excelling in Extreme Operating Conditions

The primary driver for choosing a PTFE seal is an operational environment that is too demanding for conventional materials.

High-Pressure and High-Speed Capability

PTFE lip seals are specifically designed for dynamic, rotating applications. They can reliably maintain a tight seal in systems with pressures exceeding 35 BAR (500 psi).

Critically, they can also handle shaft surface speeds greater than 35 m/s (or 10,000 sfpm), preventing the rapid wear and failure that would occur with standard seals under such conditions.

Unmatched Temperature Range

These seals function effectively across an exceptionally wide temperature spectrum. They maintain their integrity and sealing capability from cryogenic lows of -53°C (-65°F) up to 232°C (450°F).

This thermal stability makes them indispensable in aerospace, automotive turbochargers, and industrial compressors where temperature fluctuations are severe.

Superior Chemical Inertness

The PTFE material is virtually inert to most industrial chemicals, acids, and solvents. This makes it the default choice for equipment in the pharmaceutical, chemical processing, and semiconductor industries.

Unlike elastomers that can swell, degrade, or dissolve when exposed to aggressive media, PTFE remains dimensionally stable and effective.

The Inherent Advantages of PTFE Material

Beyond performance under stress, the fundamental properties of PTFE itself offer significant benefits in reliability and efficiency.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This natural lubricity reduces heat generation, minimizes wear on the rotating shaft, and lowers the energy required to operate the equipment.

Durability in Abrasive or Dry Media

The low-friction, non-stick surface allows PTFE seals to operate in dry-running conditions or in the presence of abrasive media. A standard elastomer seal would be quickly destroyed in such an environment.

Longevity and Reliability

In the right applications, such as industrial air compressors, PTFE seals have a documented service life of over 40,000 maintenance-free hours.

Furthermore, PTFE does not degrade over time from exposure to air or UV light, giving it an unlimited shelf life. This simplifies inventory management compared to elastomers, which have a finite shelf life.

Understanding the Trade-offs

While powerful, PTFE seals are an engineered solution, not a universal replacement. Objectivity requires acknowledging their specific limitations.

Less Forgiving Installation

PTFE is a harder, less elastic material than rubber. It lacks the "memory" of an elastomer and can be damaged if scratched or improperly stretched during installation. Care must be taken to use proper tools and techniques to ensure a perfect seal.

Higher Initial Cost

As a high-performance component designed for demanding roles, a PTFE seal typically has a higher upfront cost than a standard nitrile or Viton lip seal. This cost is justified by its longer life and the prevention of costly downtime in critical systems.

Sealing Surface Requirements

Because PTFE is less compliant than rubber, it requires a smoother, higher-quality shaft surface finish to achieve a reliable seal. Any imperfections on the shaft are more likely to create a leak path.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's capabilities to your primary operational challenge.

- If your primary focus is high-speed rotation or high pressure: PTFE is the superior choice for its ability to handle extreme dynamic stress without premature wear or heat buildup.

- If your application involves aggressive chemicals or extreme temperatures: The inherent inertness and thermal stability of PTFE make it a necessity, not just an option.

- If your priority is minimizing maintenance in a critical system: The extended service life of PTFE seals provides a lower total cost of ownership despite a higher initial price.

- If you are sealing a standard, low-stress application: A traditional elastomer seal is often the more forgiving and cost-effective solution.

Ultimately, choosing a PTFE lip seal is a strategic decision to ensure reliability when conditions exceed the boundaries of conventional materials.

Summary Table:

| Key Advantage | Description |

|---|---|

| High Pressure & Speed | Handles pressures >35 BAR and speeds >35 m/s. |

| Wide Temperature Range | Operates from -53°C to 232°C. |

| Chemical Inertness | Resists virtually all industrial chemicals and solvents. |

| Low Friction | Reduces heat, wear, and energy consumption. |

| Long Service Life | Can exceed 40,000 maintenance-free hours. |

Need a reliable sealing solution for your demanding application? KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates flawlessly under extreme conditions. Contact our experts today to discuss your specific requirements and get a custom solution that guarantees performance and longevity.

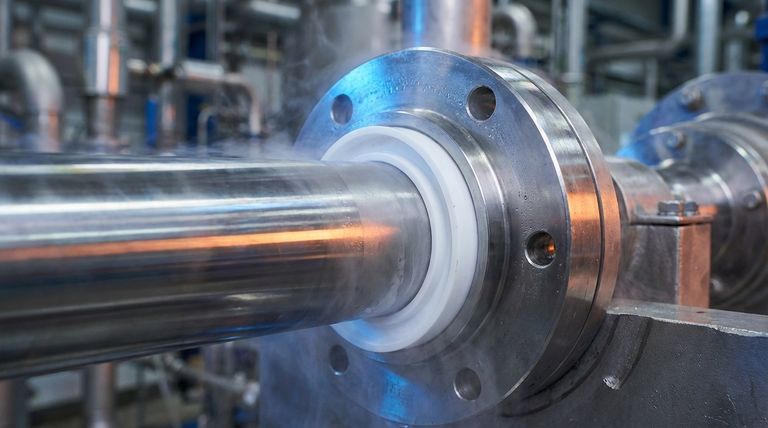

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments