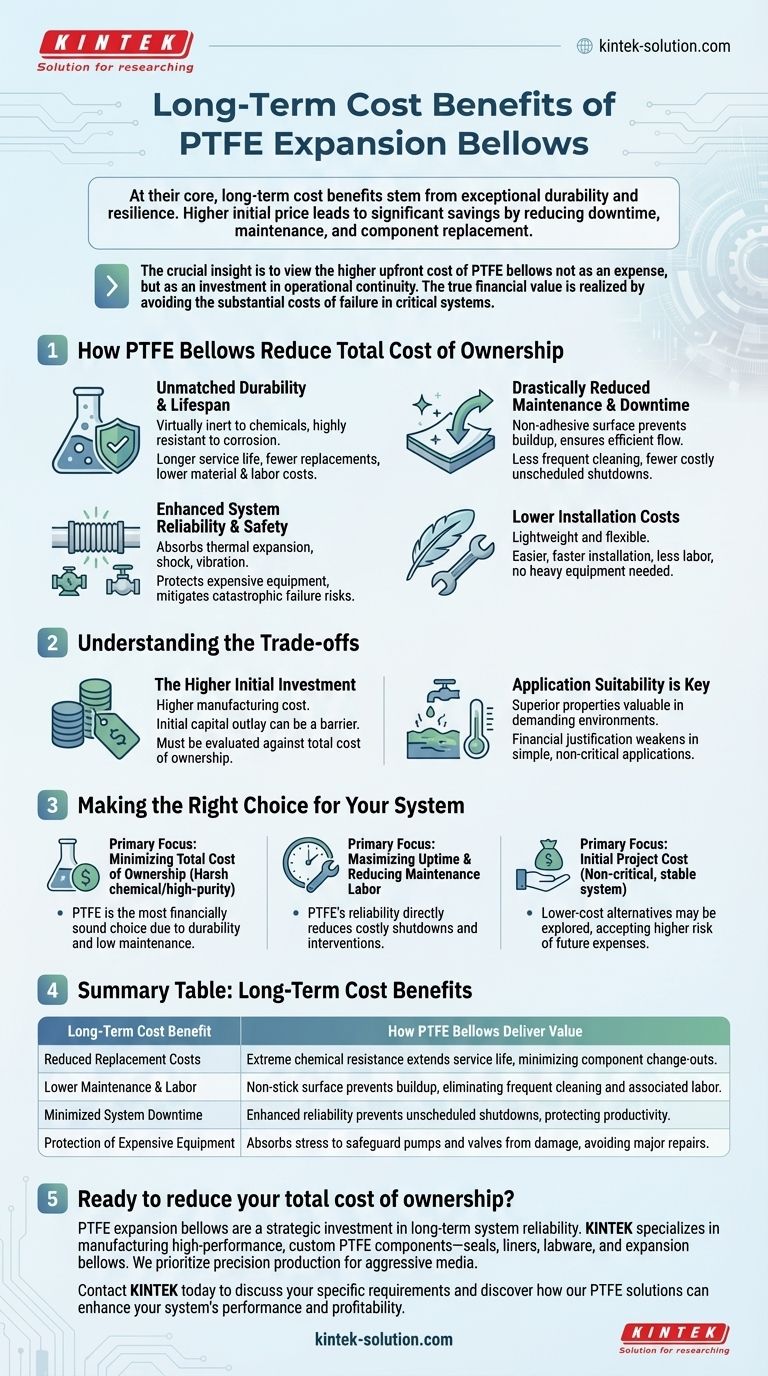

At their core, the long-term cost benefits of PTFE expansion bellows stem from their exceptional durability and resilience in demanding environments. While they carry a higher initial purchase price, they generate significant savings over time by dramatically reducing costs associated with system downtime, maintenance labor, and frequent component replacement.

The crucial insight is to view the higher upfront cost of PTFE bellows not as an expense, but as an investment in operational continuity. The true financial value is realized by avoiding the substantial costs of failure in critical systems.

How PTFE Bellows Reduce Total Cost of Ownership

The financial advantages of PTFE expansion bellows are a direct result of their unique material properties. Each feature is engineered to minimize long-term operational costs in challenging industrial settings.

Unmatched Durability and Lifespan

PTFE is virtually inert to most industrial chemicals and highly resistant to corrosion. This chemical resistance means the bellows will not degrade when exposed to aggressive media, leading to a much longer service life compared to alternatives like rubber or metal.

Fewer replacements translate directly to lower material costs and reduced labor for change-outs over the system's lifetime.

Drastically Reduced Maintenance and Downtime

A key feature of PTFE is its non-adhesive (non-stick) surface. This property prevents materials from building up inside the bellows, ensuring efficient fluid flow and eliminating the need for frequent cleaning.

This reduces scheduled maintenance and prevents costly unscheduled shutdowns caused by blockages, directly impacting operational uptime and productivity.

Enhanced System Reliability and Safety

PTFE bellows are designed to absorb thermal expansion, shock, and vibration within a pipeline system. By compensating for these stresses, they protect more expensive equipment like pumps, vessels, and valves from damage.

This function acts as a low-cost insurance policy, mitigating the risk of catastrophic system failures and enhancing overall plant safety.

Lower Installation Costs

Despite their robustness, PTFE bellows are lightweight and flexible. This makes them easier and faster to install than their metallic counterparts, often requiring less labor and no specialized heavy equipment, which reduces the initial project cost.

Understanding the Trade-offs

To make a fully informed decision, it's essential to weigh the primary drawback against the extensive benefits.

The Higher Initial Investment

The most significant consideration is the upfront cost. PTFE expansion bellows are more expensive to manufacture than many alternatives. This initial capital outlay can be a barrier for projects with tight budgets.

However, this cost must be evaluated against the total cost of ownership. In the right application, the savings from avoided downtime and maintenance will far exceed the initial price difference.

Application Suitability is Key

The superior properties of PTFE are most valuable in demanding environments. For systems handling non-corrosive fluids at stable temperatures and low pressures, a less expensive material might be a more cost-effective choice.

The financial justification for PTFE weakens significantly in simple, non-critical applications where component failure carries minimal consequences.

Making the Right Choice for Your System

Selecting the correct expansion bellow is a strategic decision that should align with your primary operational goals.

- If your primary focus is minimizing total cost of ownership in a harsh chemical or high-purity environment: The superior durability and low maintenance of PTFE make it the most financially sound choice.

- If your primary focus is maximizing uptime and reducing maintenance labor: PTFE's reliability and non-stick properties directly reduce the frequency of costly shutdowns and interventions.

- If your primary focus is initial project cost for a non-critical, stable system: You may explore lower-cost alternatives, but you must accept the higher risk of future replacement and maintenance expenses.

Ultimately, choosing PTFE expansion bellows is a strategic investment in the long-term reliability and financial health of your entire system.

Summary Table:

| Long-Term Cost Benefit | How PTFE Bellows Deliver Value |

|---|---|

| Reduced Replacement Costs | Extreme chemical resistance extends service life, minimizing component change-outs. |

| Lower Maintenance & Labor | Non-stick surface prevents buildup, eliminating frequent cleaning and associated labor. |

| Minimized System Downtime | Enhanced reliability prevents unscheduled shutdowns, protecting productivity. |

| Protection of Expensive Equipment | Absorbs stress to safeguard pumps and valves from damage, avoiding major repairs. |

Ready to reduce your total cost of ownership?

PTFE expansion bellows are a strategic investment in long-term system reliability and cost savings. For engineers and project managers in the semiconductor, pharmaceutical, chemical processing, and other demanding industries, the right component is critical.

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and expansion bellows. We prioritize precision production to ensure your components withstand aggressive media and deliver on their promise of durability.

Whether you need a prototype for testing or a high-volume order for a full-scale operation, our custom fabrication expertise ensures a perfect fit for your application.

Contact KINTEB today to discuss your specific requirements and discover how our PTFE solutions can enhance your system's performance and profitability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech