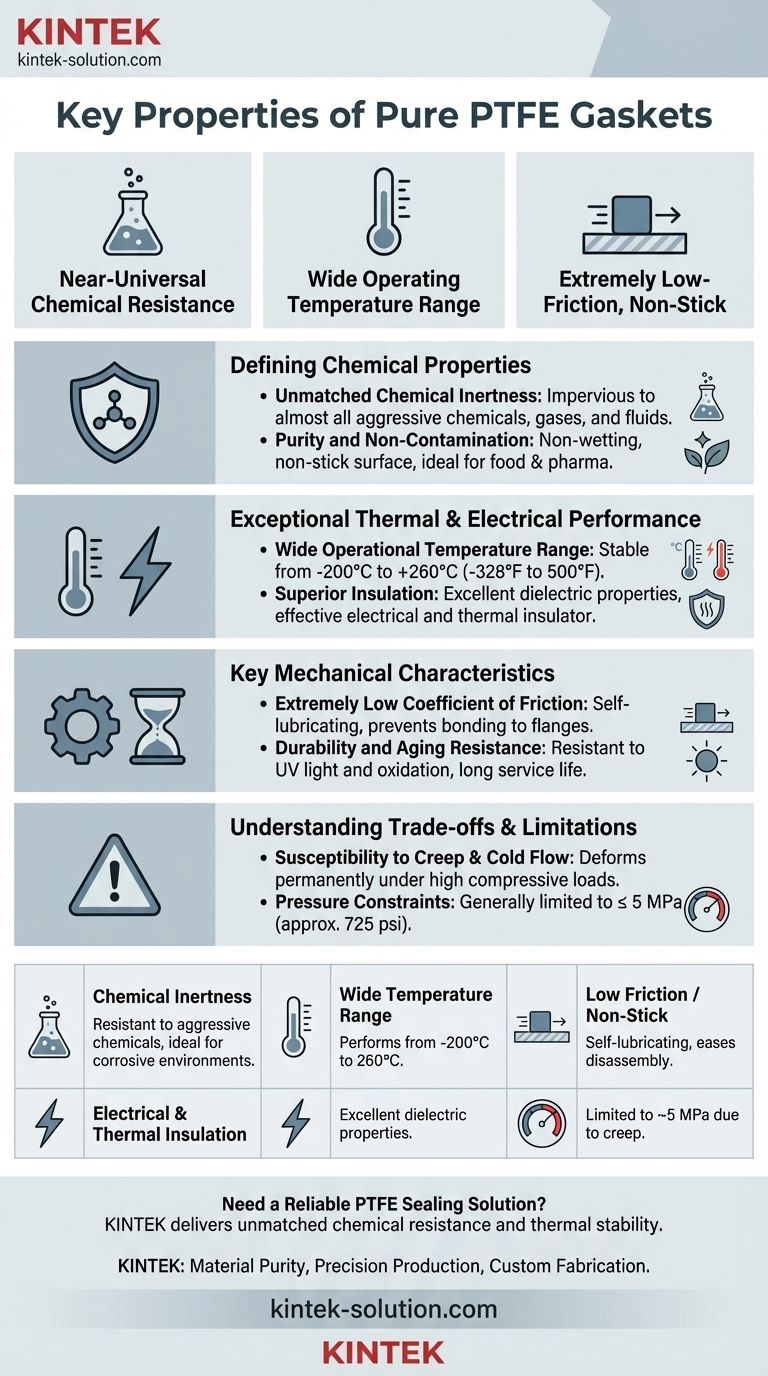

At its core, a pure Polytetrafluoroethylene (PTFE) gasket is defined by three primary characteristics: near-universal chemical resistance, an exceptionally wide operating temperature range, and an extremely low-friction, non-stick surface. These properties make it a premier choice for sealing applications where purity and resistance to aggressive media are critical.

A pure PTFE gasket is the default solution for sealing in highly corrosive chemical environments or applications requiring absolute purity, like food and pharmaceuticals. Its primary limitation, however, is mechanical, as it is not suited for high-pressure systems without reinforcement.

The Defining Chemical Properties

The most renowned characteristic of PTFE is its chemical inertness. This quality stems from its unique molecular structure, making it non-reactive in nearly all industrial contexts.

Unmatched Chemical Inertness

Pure PTFE is impervious to attack and degradation from almost all aggressive gases, vapors, and fluids. This makes it one of the most chemically resistant materials available for sealing.

It is fundamentally non-corrosive, meaning it will not react with or damage the flange surfaces it is sealing against.

Purity and Non-Contamination

PTFE has a non-wetting and non-stick surface, which prevents process media from adhering to the gasket. This is critical in applications where cleanliness is paramount.

Because it does not leach or contaminate, it is an ideal clean sealing solution for the food, beverage, and pharmaceutical industries.

Exceptional Thermal and Electrical Performance

Beyond its chemical stability, PTFE excels in environments with extreme temperature fluctuations and where electrical insulation is required.

Wide Operational Temperature Range

Pure PTFE maintains its mechanical integrity and sealing capability across a vast temperature spectrum, typically from cryogenic levels around -200°C (-328°F) up to 260°C (500°F).

This stability at both high and low temperatures allows it to be used in a diverse range of processes without becoming brittle or degrading.

Superior Insulation

PTFE exhibits excellent dielectric properties, making it a highly effective electrical insulator. It also provides good thermal insulation between flange faces.

Key Mechanical Characteristics

While not known for high strength, PTFE's mechanical properties are essential to its function as a gasket material.

Extremely Low Coefficient of Friction

The material is self-lubricating and has one of the lowest friction coefficients of any solid. This non-stick quality aids in disassembly, preventing the gasket from bonding to flange surfaces.

Durability and Aging Resistance

PTFE is highly resistant to aging from environmental factors like UV light and oxidation. It does not degrade over time, ensuring a long and reliable service life in static applications.

Understanding the Trade-offs and Limitations

To select PTFE correctly, you must understand its mechanical weaknesses. Its unparalleled chemical and thermal properties come with distinct physical constraints.

Susceptibility to Creep and Cold Flow

The most significant limitation of pure PTFE is its tendency to "creep" or cold flow. When subjected to high compressive loads, the material can deform permanently and extrude out of the flange.

Pressure Constraints

Due to this tendency to creep, pure PTFE gaskets are generally limited to lower-pressure applications, often cited as being suitable for pressures up to 5 MPa (approximately 725 psi). For higher pressures, filled or expanded PTFE variants are required.

Making the Right Choice for Your Application

Selecting the right gasket material requires balancing chemical, thermal, and mechanical demands.

- If your primary focus is sealing aggressive chemicals or preventing contamination: Pure PTFE is an unparalleled choice due to its near-universal inertness and inherent purity.

- If your application involves a wide temperature range: PTFE's consistent performance from cryogenic lows to high heat makes it exceptionally versatile and reliable.

- If your system operates under high pressure or has uneven flanges: You must consider modified PTFE options, as pure PTFE's tendency to cold flow makes it unsuitable for high-load applications.

Ultimately, choosing pure PTFE is a decision to prioritize chemical and thermal resilience above high mechanical strength.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to almost all aggressive chemicals, gases, and fluids. | Ideal for corrosive environments and pure processes (food, pharma). |

| Wide Temperature Range | Performs from -200°C (-328°F) to 260°C (500°F). | Versatile for cryogenic and high-heat applications. |

| Low Friction / Non-Stick | Self-lubricating with an extremely low coefficient of friction. | Prevents media adhesion and eases disassembly. |

| Electrical & Thermal Insulation | Excellent dielectric properties and thermal insulation. | Protects against electrical conduction and heat transfer. |

| Pressure Limitation | Limited to ~5 MPa (725 psi) due to creep/cold flow. | Best for low to medium-pressure systems; reinforced PTFE needed for higher pressures. |

Need a Reliable PTFE Sealing Solution?

Pure PTFE gaskets from KINTEK deliver the unmatched chemical resistance and thermal stability your critical applications demand. We specialize in manufacturing high-precision PTFE components, including custom gaskets, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors.

We ensure:

- Material Purity: Perfect for contamination-sensitive environments.

- Precision Production: Consistent performance and reliable seals.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

Let us provide the perfect PTFE seal for your system. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability