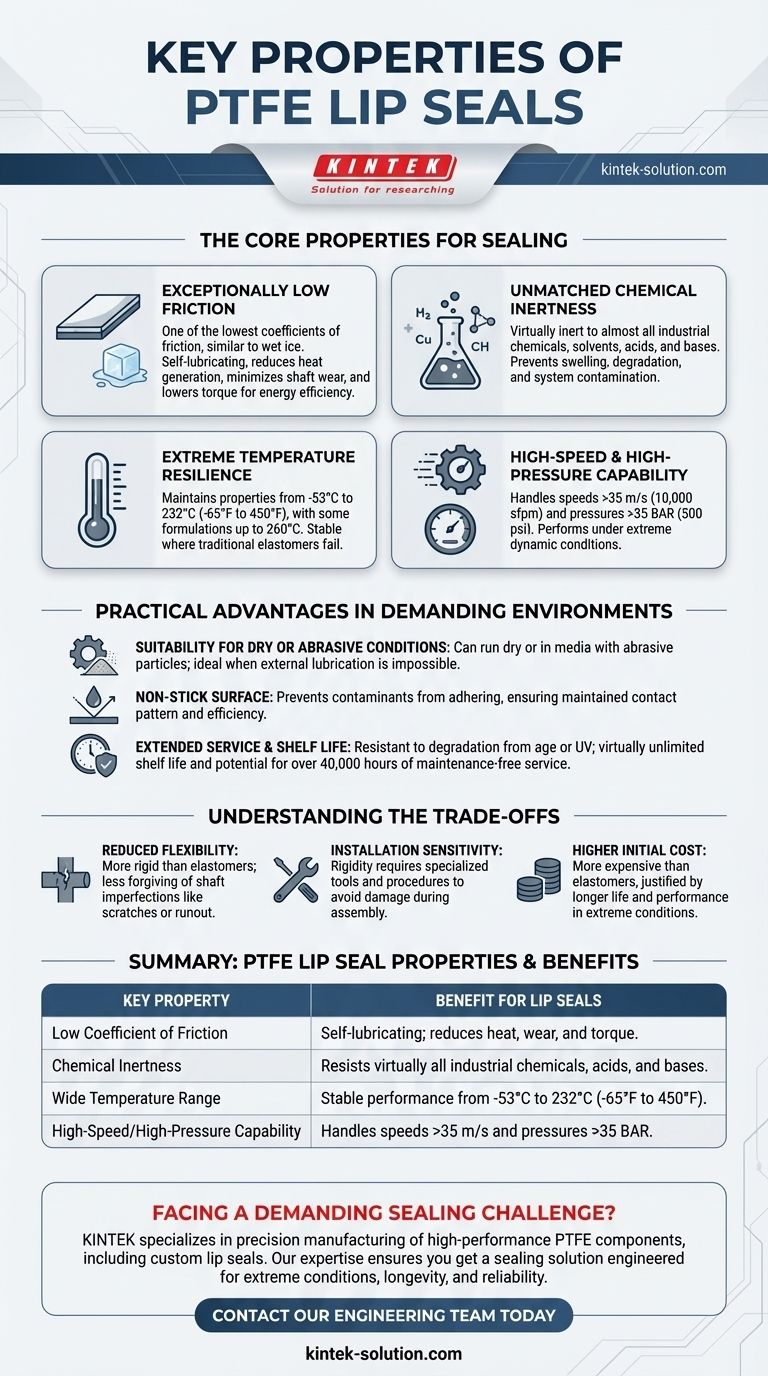

At its core, a PTFE lip seal is chosen for its unique combination of four key properties: an exceptionally low coefficient of friction, unparalleled chemical inertness, a very wide operating temperature range, and the ability to withstand high speeds and pressures. These characteristics allow it to succeed in demanding applications where conventional elastomeric seals would quickly fail.

The decision to use a PTFE lip seal is fundamentally a decision to solve a problem. It is specified when operational conditions—be it extreme temperature, aggressive chemicals, high surface speeds, or a lack of lubrication—exceed the physical limits of traditional sealing materials.

The Core Properties of PTFE for Sealing

To understand why PTFE is a superior material for challenging environments, we must look at how its intrinsic properties translate into functional advantages.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "self-lubricating" property is critical in a seal.

It directly reduces heat generation at the contact point, minimizes wear on the rotating shaft, and lowers the torque required to turn the shaft, contributing to energy efficiency.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, solvents, acids, and bases.

This ensures the seal will not swell, degrade, or break down when exposed to aggressive media. This preserves the seal's integrity and prevents contamination of the system fluid.

Extreme Temperature Resilience

PTFE maintains its properties across a vast temperature spectrum, typically from -53°C to 232°C (-65°F to 450°F), with some formulations performing up to 260°C.

Where traditional elastomers would become brittle at low temperatures or soften and degrade at high temperatures, PTFE remains stable and effective.

High-Speed and High-Pressure Capability

The combination of low friction and material stability allows PTFE seals to perform under extreme dynamic conditions.

They can handle surface speeds exceeding 35 m/s (10,000 sfpm) and system pressures over 35 BAR (500 psi), conditions that would cause rapid failure in most other seal types.

Practical Advantages in Demanding Environments

These fundamental properties give rise to several practical benefits that make PTFE the material of choice for specific operational challenges.

Suitability for Dry or Abrasive Conditions

Because of its self-lubricating nature, a PTFE lip seal can run dry or in media with abrasive particles without failing prematurely. This is a critical advantage in applications where consistent external lubrication is impossible.

Non-Stick Surface

The non-stick characteristic of PTFE prevents contaminants or system media from adhering to the seal lip. This ensures the seal maintains its intended contact pattern and efficiency over its service life.

Extended Service and Shelf Life

PTFE does not degrade with age or exposure to UV light, giving it a virtually unlimited shelf life. In operation, its resistance to wear and chemical attack can lead to extremely long, maintenance-free service, sometimes exceeding 40,000 hours.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal replacement for all other seal types. A clear understanding of their limitations is essential for proper application.

Reduced Flexibility

Compared to elastomers, PTFE is a much more rigid material. This makes it less forgiving of shaft imperfections, such as scratches or runout. Proper shaft surface preparation is critical.

Installation Sensitivity

The material's rigidity can also make installation more challenging than with a flexible rubber seal. Specialized tools and procedures are often required to avoid damaging the seal lip during assembly.

Higher Initial Cost

PTFE seals are typically more expensive than their common elastomeric counterparts. Their use is justified by the need for longer life, reduced downtime, and performance in conditions where a cheaper seal would simply not survive.

Making the Right Choice for Your Application

Selecting the correct seal material comes down to matching the material's capabilities to the demands of the operating environment.

- If your primary focus is extreme temperature or chemical exposure: PTFE is the superior choice due to its inherent material stability where elastomers would rapidly degrade.

- If your primary focus is high-speed rotational applications: PTFE's low-friction properties minimize heat buildup and shaft wear, enabling performance beyond the limits of standard seals.

- If your application involves dry running or abrasive media: PTFE's self-lubricating and durable nature provides a reliable sealing solution where lubricated seals are not feasible.

- If your application is standard and cost-sensitive: A traditional elastomeric seal is often more cost-effective and forgiving of minor hardware imperfections.

By understanding these core properties and trade-offs, you can confidently specify the right sealing material for even the most demanding operational challenges.

Summary Table:

| Key Property | Benefit for Lip Seals |

|---|---|

| Low Coefficient of Friction | Self-lubricating; reduces heat, wear, and torque. |

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases. |

| Wide Temperature Range | Stable performance from -65°F to 450°F (-53°C to 232°C). |

| High-Speed/High-Pressure Capability | Handles speeds >35 m/s and pressures >35 BAR. |

Facing a demanding sealing challenge that standard seals can't handle?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution engineered for extreme conditions, longevity, and reliability.

Contact our engineering team today to discuss your specific application requirements and discover how our PTFE seals can solve your most critical sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency