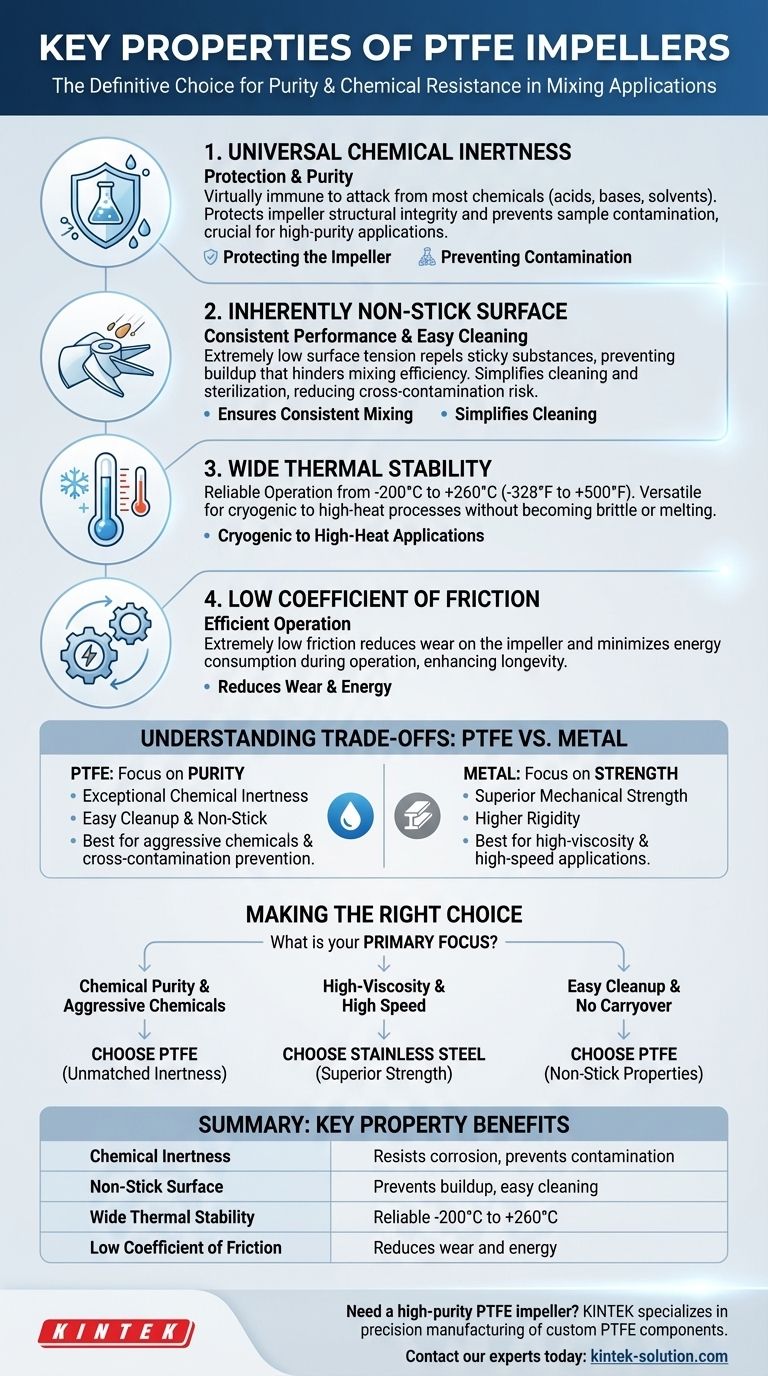

The suitability of PTFE for impellers stems from a unique combination of four core properties: its universal chemical resistance, an inherently non-stick surface, wide thermal stability, and an extremely low coefficient of friction. These characteristics ensure the impeller can operate reliably in harsh chemical environments without degrading, contaminating the substance being mixed, or accumulating residue that would hinder performance.

The core reason PTFE excels for impellers is its combination of inertness and cleanability. This makes it the definitive choice for applications where sample purity and preventing cross-contamination are more critical than the raw mechanical strength offered by alternatives like stainless steel.

Why Chemical Inertness is Paramount

The single most important property of Polytetrafluoroethylene (PTFE) for impeller design is its near-total chemical inertness. This quality provides two distinct, critical advantages.

Protecting the Impeller from Corrosive Fluids

An impeller is, by definition, in constant, aggressive contact with the fluid it is mixing. PTFE is virtually immune to attack from almost all chemicals, including strong acids, bases, and organic solvents.

This ensures the impeller maintains its structural integrity and shape over time, providing consistent performance in environments that would quickly corrode even high-grade metals.

Preventing Contamination of the Sample

Just as the fluid cannot harm the PTFE, the PTFE cannot harm the fluid. Because it is inert, the impeller will not leach ions or other substances into the mixture.

This is non-negotiable in laboratory, pharmaceutical, and high-purity industrial applications where even trace contamination can invalidate an experiment or ruin a product batch.

The Functional Advantage of a Non-Stick Surface

PTFE has extremely low surface tension, giving it the famous non-stick quality also known by the brand name Teflon®. This is not just a convenience; it is a key performance feature.

Ensuring Consistent Mixing Performance

Many processes involve sticky or viscous substances like polymers, adhesives, or biological materials. A PTFE impeller’s non-stick surface repels these substances, preventing them from building up on the blades.

Residue buildup alters the impeller's geometry, which reduces mixing efficiency and creates inconsistent results. PTFE minimizes this risk.

Simplifying Cleaning and Sterilization

The non-stick property makes PTFE impellers exceptionally easy to clean. This reduces downtime between different batches and, more importantly, drastically lowers the risk of cross-contamination.

Operating Across Extreme Temperatures

An impeller may be used in processes that require significant heating or cooling. PTFE’s ability to perform reliably across a vast temperature range makes it a highly versatile choice.

From Cryogenic to High-Heat Applications

PTFE maintains its properties in a working temperature range from approximately -200°C to +260°C (-328°F to +500°F).

This allows the same impeller design to be used for cryogenic applications and for mixing high-temperature materials without risk of it becoming brittle or melting.

Understanding the Trade-offs: PTFE vs. Metal

While its properties are exceptional, PTFE is not the solution for every application. Its primary limitations are mechanical, especially when compared to stainless steel.

The Limitation of Mechanical Strength

The most significant trade-off is that PTFE has relatively low strength and rigidity. It is a much softer material than steel.

In applications involving extremely high-viscosity fluids or requiring very high rotational speeds, a PTFE impeller can deform or fail under the intense mechanical stress.

The Impact of Thermal Expansion

PTFE has a high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes.

In systems with very tight tolerances between the impeller and the vessel wall, this must be accounted for in the design to prevent binding or scraping.

Making the Right Choice for Your Application

Choosing between PTFE and a material like stainless steel depends entirely on the primary demands of your process.

- If your primary focus is chemical purity and handling aggressive chemicals: PTFE is the superior choice due to its unmatched inertness and corrosion resistance.

- If your primary focus is mixing highly viscous materials at high speeds: Stainless steel is often required for its superior mechanical strength and rigidity.

- If your primary focus is easy cleanup and preventing sample carryover: PTFE's non-stick properties make it significantly more efficient and reliable than metal.

Ultimately, selecting a PTFE impeller is a decision to prioritize chemical compatibility and cleanliness over raw mechanical force.

Summary Table:

| Key Property | Benefit for Impeller Application |

|---|---|

| Chemical Inertness | Resists corrosion from acids, bases, and solvents; prevents sample contamination. |

| Non-Stick Surface | Prevents residue buildup for consistent mixing and easy cleaning/sterilization. |

| Wide Thermal Stability | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Coefficient of Friction | Reduces wear and energy consumption during operation. |

Need a high-purity PTFE impeller for your application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including impellers, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors where contamination control and chemical resistance are critical.

We can fabricate your PTFE impeller from prototype to high-volume production, ensuring it meets your exact specifications for performance and purity.

Contact our experts today to discuss your impeller requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability