At its core, Polytetrafluoroethylene (PTFE) is defined by a unique combination of extreme performance characteristics. The key properties of PTFE pipes are their near-total chemical inertness, an exceptionally wide operating temperature range, and the lowest coefficient of friction of any known solid material, which creates an incredibly smooth, non-stick surface.

The decision to use PTFE is rarely about its physical strength; it's about its unparalleled ability to survive and perform in extreme chemical and thermal environments where nearly all other plastics would fail. Understanding this distinction is critical to its proper application.

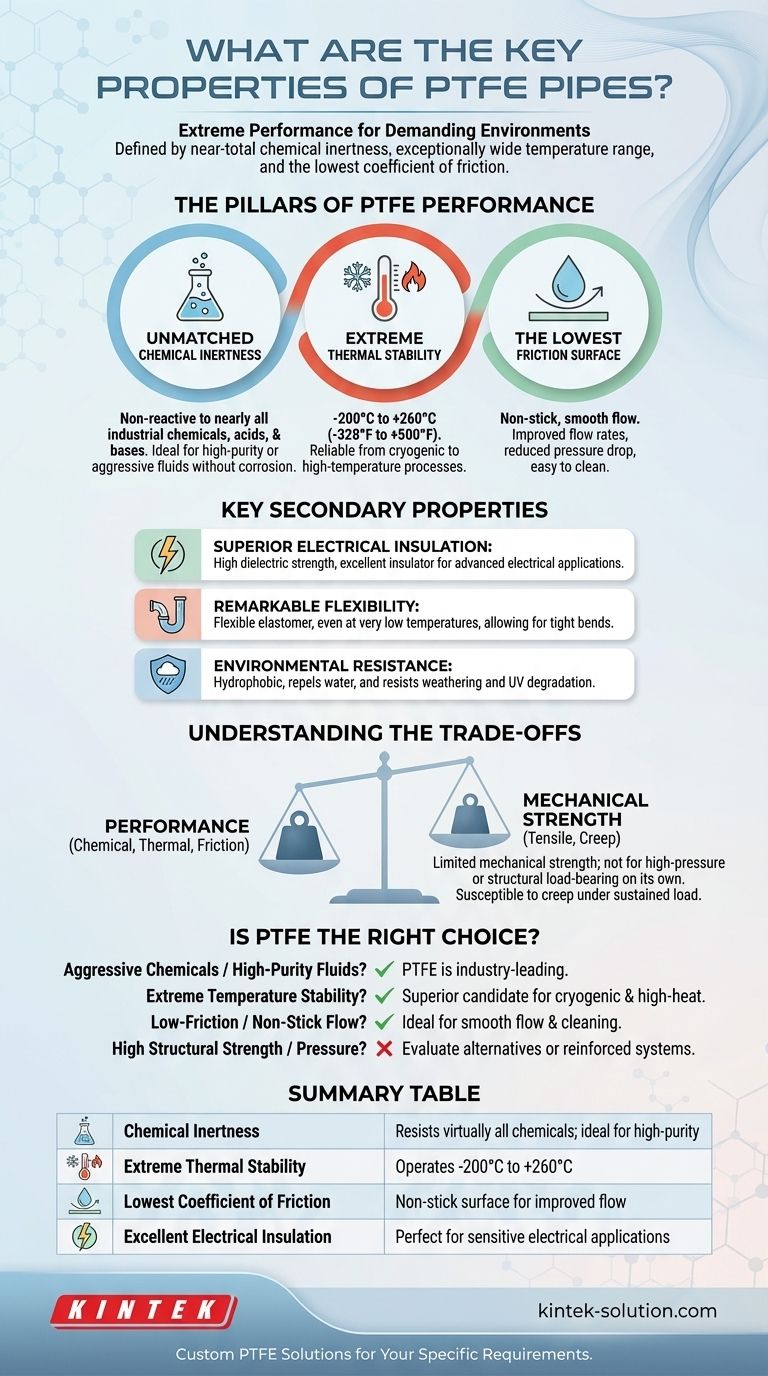

The Pillars of PTFE Performance

The value of PTFE pipe comes from a trifecta of properties that make it a premier choice for demanding industrial, chemical, and scientific applications.

Unmatched Chemical Inertness

PTFE is non-reactive to nearly all industrial chemicals, acids, and bases. This is due to the strong carbon-fluorine bonds that make up its structure.

This inertness makes it the material of choice for transporting high-purity fluids or aggressive chemicals without risk of corrosion, contamination, or pipe degradation.

Extreme Thermal Stability

PTFE pipes maintain their properties across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to handle everything from cryogenic applications to high-temperature chemical processes, performing reliably where materials like PVC or rubber would become brittle or melt.

The Lowest Friction Surface

PTFE has the lowest coefficient of friction of any solid, a property that makes Teflon® famous. This results in a smooth, non-stick surface.

For fluid transport, this means improved flow rates and reduced pressure drop. It also makes the pipes easy to clean and resistant to buildup or biofouling.

Key Secondary Properties

Beyond the core three, several other characteristics contribute to PTFE's versatility.

Superior Electrical Insulation

PTFE possesses a high dielectric strength, meaning it is an excellent electrical insulator. It resists the flow of electricity exceptionally well.

This property makes it indispensable in advanced electrical applications, such as insulators for high-frequency data cables and components for semiconductors.

Remarkable Flexibility

Despite its durability, PTFE is a flexible elastomer, even at very low temperatures where other materials would become rigid and crack.

This allows it to be used in applications requiring tight bends and complex routing without compromising its structural integrity.

Environmental Resistance

PTFE is hydrophobic, meaning it repels water and resists moisture absorption. It is also highly resistant to weathering and UV degradation, making it suitable for long-term use in exposed environments.

Understanding the Trade-offs

No material is perfect. To use PTFE effectively, you must understand its limitations.

Limited Mechanical Strength

The primary trade-off with PTFE is its relatively low tensile strength compared to metals or other engineered polymers. It is not designed for high-pressure or structural load-bearing applications on its own.

It is a flexible material, not a rigid one. In high-pressure situations, it often requires external reinforcement or support.

Susceptibility to Creep

Under a sustained mechanical load, especially at elevated temperatures, PTFE can be susceptible to "creep," or slow deformation over time. This must be considered in the design of fittings and support structures.

Is PTFE the Right Choice for Your Application?

Choosing the correct material requires aligning its properties with your primary goal.

- If your primary focus is handling aggressive chemicals or high-purity fluids: PTFE is an industry-leading choice due to its near-total chemical inertness.

- If your primary focus is extreme temperature stability: PTFE's vast operating range makes it a superior candidate for both cryogenic and high-heat systems.

- If your primary focus is low-friction or non-stick fluid transport: The exceptionally low coefficient of friction makes it ideal for ensuring smooth flow and easy cleaning.

- If your primary focus is high structural strength or pressure containment: You should evaluate alternative materials or consider reinforced PTFE piping systems, as standard PTFE is not a structural plastic.

By understanding these core properties and their inherent trade-offs, you can confidently determine if PTFE's unique strengths align with the demands of your project.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Chemical Inertness | Resists virtually all chemicals, acids, and bases; ideal for high-purity or aggressive fluids. |

| Extreme Thermal Stability | Operates reliably from -200°C to +260°C, handling cryogenic to high-temperature processes. |

| Lowest Coefficient of Friction | Provides a non-stick surface for improved flow rates, reduced clogging, and easy cleaning. |

| Excellent Electrical Insulation | High dielectric strength makes it perfect for sensitive electrical and semiconductor applications. |

Need a PTFE solution tailored to your specific chemical, thermal, or flow requirements?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom pipes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to ensure your system performs reliably in the most demanding environments.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some general applications of PTFE with fillers? Enhance Performance in Demanding Seals & Bearings

- What are the primary functions of PTFE expansion bellows? Absorb Movement, Dampen Vibration, and Protect Pipes

- What are the differences between Teflon and rubber sealed bearings? Choose the Right Seal for Speed or Protection

- What types of semi-finished parts are available? Choose the Right Stock Shape for Your Project

- How can Teflon PTFE sheets assist in crafting with glue or resin? Achieve a Clean, Reusable Workspace

- What are the main industries that use PTFE lip seals? Solve Extreme Sealing Challenges

- Can a towel be used instead of a Teflon sheet for heat press? A High-Risk Shortcut Explained

- Why is deburring critical after machining PTFE? Ensure Component Integrity and Reliability