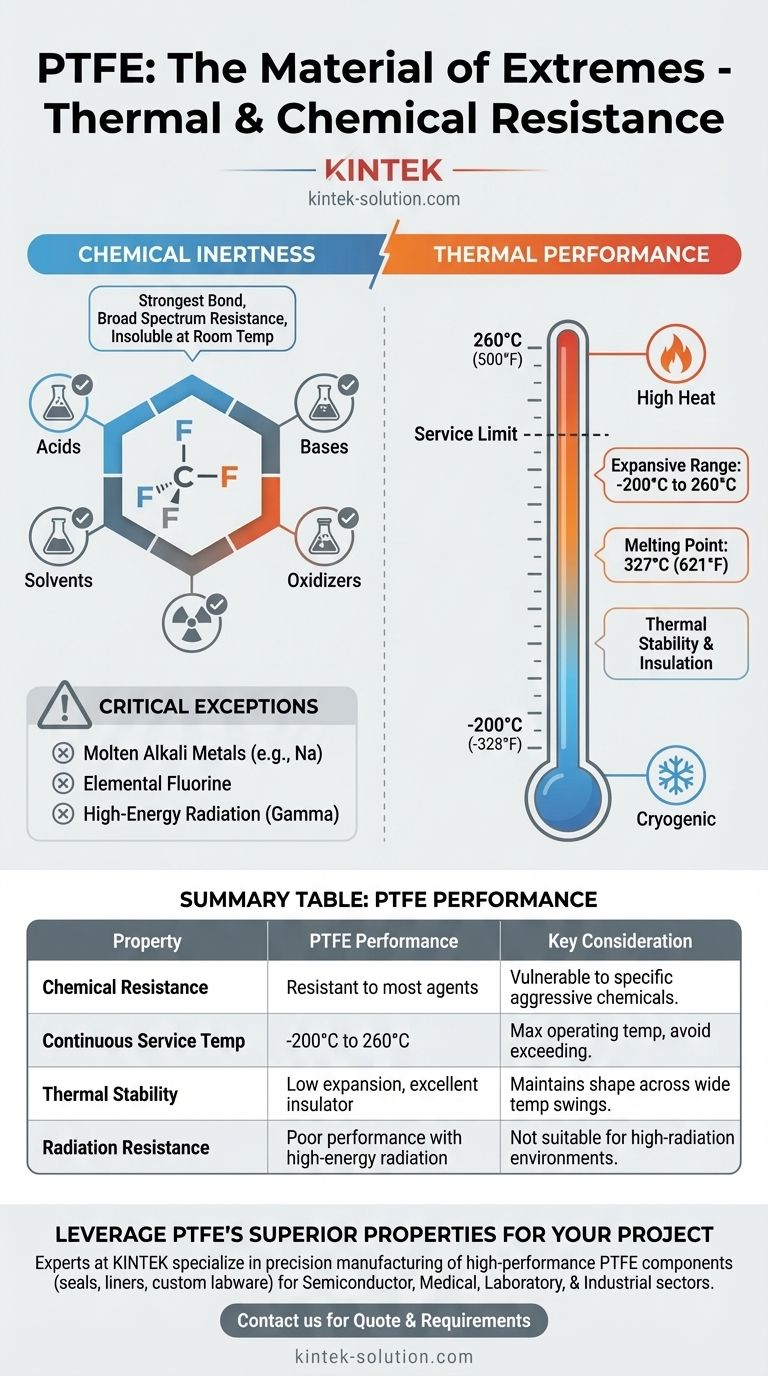

At its core, Polytetrafluoroethylene (PTFE) is a material of extremes. It offers an unparalleled combination of chemical inertness and thermal stability, making it one of the most resilient plastics available. Its ability to function across a vast temperature range from cryogenic lows to high heat, while remaining unaffected by nearly all corrosive chemicals, defines its primary value in demanding industrial and scientific applications.

The key takeaway is that PTFE's value comes from its near-total chemical inertness and exceptional thermal range. However, this resilience is not absolute; its performance limitations with specific aggressive chemicals like molten alkali metals and elemental fluorine are critical to understand for safe and effective use.

Deconstructing PTFE's Unmatched Chemical Inertness

The chemical resistance of PTFE is legendary, but understanding the source of this property is key to using it effectively. It isn't just strong; it is fundamentally non-reactive in most scenarios.

The Power of the Carbon-Fluorine Bond

The foundation of PTFE's stability is the powerful bond between its carbon and fluorine atoms. This bond is one of the strongest in organic chemistry, creating a molecule that is exceptionally difficult to break apart with chemical reactions.

Broad Spectrum Resistance

This molecular stability makes PTFE virtually immune to most corrosive agents. It is unaffected by aggressive acids, bases, solvents, and oxidizers, including substances like hydrochloric acid, sulfuric acid, acetone, and sodium peroxide.

A Material Defined by Insolubility

At room temperature, there are no known solvents that can dissolve PTFE. This high degree of insolubility prevents chemicals from penetrating and degrading the polymer structure from within.

Understanding PTFE's Thermal Performance

Beyond its chemical resilience, PTFE is highly valued for its ability to maintain its properties across an exceptionally wide temperature spectrum.

An Expansive Operating Temperature Range

PTFE performs reliably across a continuous service range from -200°C to 260°C (-328°F to 500°F). This makes it suitable for everything from cryogenic components to high-temperature seals and insulators.

High Melting Point vs. Service Temperature

While PTFE's technical melting point is around 327°C (621°F), its structural integrity begins to degrade before that point. For practical engineering purposes, 260°C (500°F) is considered the maximum continuous operating temperature.

Thermal Stability and Insulation

PTFE has a low coefficient of thermal expansion, meaning it maintains its shape and dimensional stability well when subjected to temperature changes. It also serves as an excellent thermal insulator.

The Critical Exceptions: When PTFE Fails

No material is perfect. While PTFE is remarkably robust, its few vulnerabilities are absolute and must be respected to prevent catastrophic failure in an application.

Chemical Vulnerabilities

PTFE's near-total inertness has a few specific, well-documented exceptions. It can be attacked and damaged by:

- Molten or dissolved alkali metals, such as sodium.

- Elemental fluorine gas, especially at elevated temperatures.

- Highly reactive fluorine compounds like chlorine trifluoride.

These substances are potent enough to break the stable carbon-fluorine bonds that give PTFE its resilience.

The Impact of High-Energy Radiation

PTFE exhibits relatively poor resistance to high-energy radiation, such as gamma rays. This type of radiation can cause scission in the polymer chains, leading to a breakdown of the material's mechanical properties.

Selecting PTFE for Your Application

Your final decision depends entirely on the specific demands of your environment.

- If your primary focus is handling corrosive chemicals: PTFE is almost certainly your best choice, provided your process does not involve its few specific chemical vulnerabilities like molten alkali metals.

- If your primary focus is performance across extreme temperatures: PTFE's stability from cryogenic levels up to 260°C makes it a premier material, but you must respect the continuous service limit to avoid degradation.

- If your primary focus is an environment with high radiation: You must seek an alternative material, as PTFE's molecular structure will be compromised and break down.

Ultimately, understanding both PTFE's remarkable strengths and its precise limitations is the key to leveraging it successfully.

Summary Table:

| Property | PTFE Performance | Key Consideration |

|---|---|---|

| Chemical Resistance | Resistant to most acids, bases, solvents, and oxidizers. | Vulnerable to molten alkali metals and elemental fluorine. |

| Continuous Service Temperature | -200°C to 260°C (-328°F to 500°F) | Maximum operating temperature; avoid exceeding 260°C. |

| Thermal Stability | Low coefficient of thermal expansion; excellent insulator. | Maintains shape and function across wide temperature swings. |

| Radiation Resistance | Poor performance with high-energy radiation (e.g., gamma rays). | Not suitable for high-radiation environments. |

Leverage PTFE's Superior Properties for Your Project

Does your application in the semiconductor, medical, laboratory, or industrial sector demand a material with extreme thermal and chemical resistance? The experts at KINTEK are here to help.

We specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—tailored to your exact specifications. From initial prototypes to high-volume production, we ensure your components deliver unmatched reliability, even in the most demanding environments.

Contact us today to discuss your requirements and get a quote: Reach out via our contact form

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is Teflon suitable for waterproof makeup products? Unlock the Secret to Smudge-Proof Wear

- How is PTFE used in the beauty industry? Enhance Product Performance and Safety

- What are the environmental properties of PTFE? Balancing Performance with Sustainability

- What makes PTFE's low friction properties advantageous for aerospace applications? Achieve Unmatched Reliability and Efficiency

- What makes PTFE plastic uniquely versatile across industries? The 4 Key Properties Explained

- What is the difference between PTFE and Teflon? Uncover the Truth to Make Smarter Sourcing Decisions

- What is the chemical name for Teflon? Unpacking PTFE's Versatile Properties

- What are the environmental concerns associated with PTFE manufacturing? Assessing the Full Lifecycle Impact