At their core, fully lined ball valves are defined by a complete, non-reactive fluoropolymer lining that isolates all internal metal components from the process media. This core feature is supported by a full port design for maximum flow, a two-piece bolted body for maintainability, and an integral ball and stem unit for structural reliability.

The defining principle of a fully lined ball valve isn't just one feature, but how all features work together to create an uncompromising chemical barrier. This design ensures that aggressive or corrosive media only ever touch an inert fluoropolymer surface, protecting the valve's structural integrity and ensuring process purity.

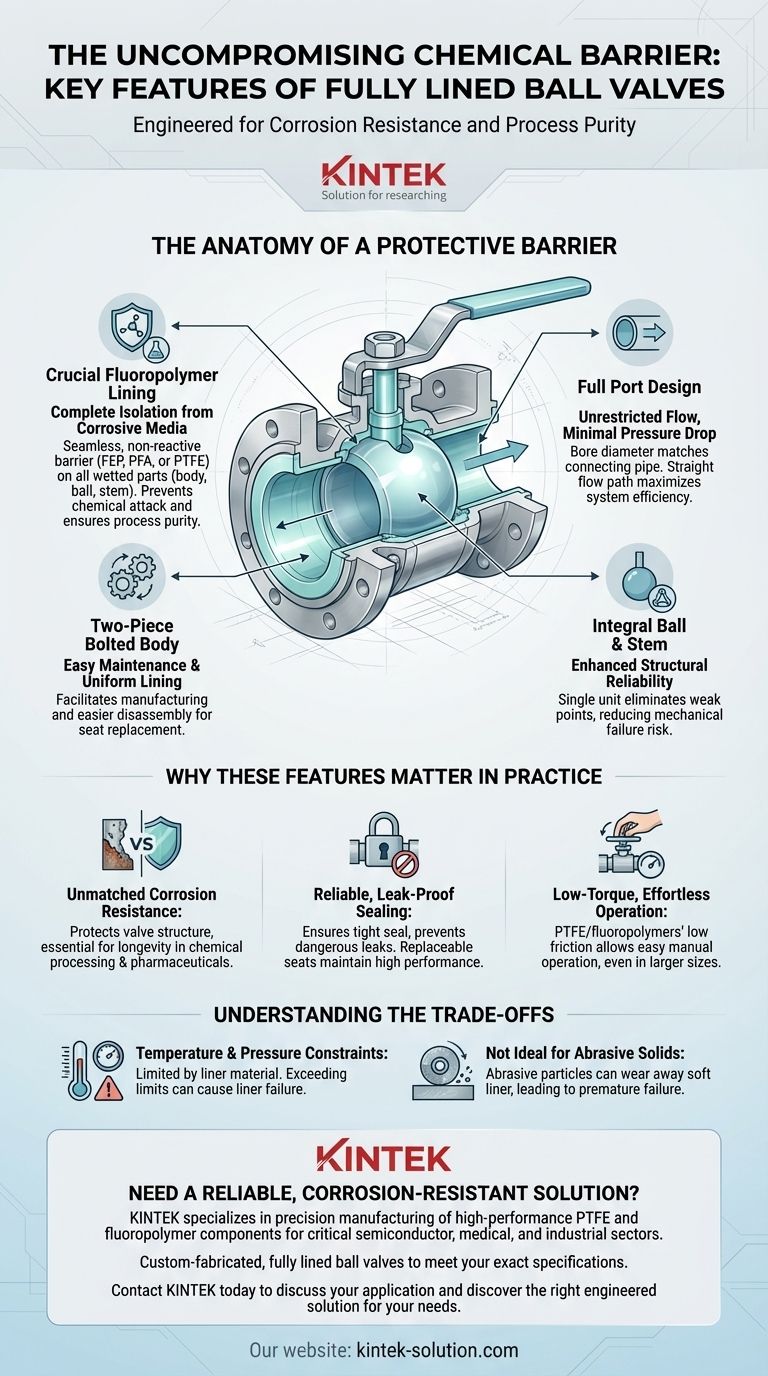

The Anatomy of a Protective Barrier

To understand the value of a fully lined ball valve, you must first understand its core components and why they are engineered a specific way. Each feature serves the primary goal of isolating and controlling corrosive fluids safely.

The Crucial Fluoropolymer Lining

The most critical feature is the uniform lining, typically made of FEP (Fluorinated Ethylene Propylene), PFA (Perfluoroalkoxy Alkane), or PTFE (Polytetrafluoroethylene).

This lining is applied to all wetted parts—the interior body, ball, and stem. This creates a seamless, non-reactive barrier that is exceptionally resistant to acids, alkalis, and other corrosive chemicals.

The non-stick properties of these materials also ensure smooth fluid flow and prevent media buildup.

Two-Piece Bolted Body Construction

The valve body is typically constructed in two pieces and bolted together. This design facilitates the complex manufacturing process of applying a uniform, high-integrity lining to all internal surfaces.

It also allows for easier disassembly and maintenance, such as replacing the valve seats.

Full Port Design for Unrestricted Flow

These valves feature a full port (or full bore) design. This means the hole in the ball is the same diameter as the connecting pipe.

The primary benefit is a straight, unobstructed flow path, which minimizes pressure drop and turbulence across the valve, maximizing system efficiency.

Integral Ball and Stem Unit

The ball and stem are often designed as a single, integrated unit. This eliminates a potential weak point between two separate components, reducing the risk of mechanical failure and improving the valve's overall durability and reliability under stress.

Why These Features Matter in Practice

The combination of these design features translates into tangible operational benefits that address the challenges of handling aggressive media.

Unmatched Corrosion Resistance

The complete lining is the first line of defense, protecting the structural metal of the valve from chemical attack. This is essential for longevity and safety in industries like chemical processing and pharmaceuticals.

Reliable, Leak-Proof Sealing

The design ensures a tight seal, preventing dangerous leaks. The fluoropolymer seats are easily replaceable, allowing you to maintain this high level of sealing performance throughout the valve's service life.

Low-Torque, Effortless Operation

PTFE and similar fluoropolymers have an extremely low coefficient of friction. This property means less force, or torque, is required to turn the ball, allowing for easy manual lever operation even in larger sizes.

Understanding the Trade-offs

While highly effective, lined valves are a specialized solution. Understanding their limitations is key to using them correctly.

Temperature and Pressure Constraints

The primary limitation of a lined valve is determined by the liner material itself. Fluoropolymers have lower temperature and pressure ratings than solid metal. Exceeding these limits can cause the liner to deform, collapse, or fail, compromising the valve.

Not Ideal for Abrasive Solids

While excellent for corrosive liquids and gases, lined valves are generally not recommended for services with significant abrasive solids or slurries. The abrasive particles can wear away or damage the soft liner over time, leading to premature failure.

Making the Right Choice for Your Application

Selecting the right valve depends entirely on the demands of your specific process.

- If your primary focus is handling highly corrosive chemicals: The complete fluoropolymer lining is your most critical feature, ensuring total isolation and long-term reliability.

- If your primary focus is maintaining process purity (e.g., pharma, food): The non-stick, inert properties of the PTFE/PFA lining prevent contamination and ensure smooth, clean flow.

- If your primary focus is maximizing flow efficiency: The full-port design eliminates pressure drop, making it the ideal choice for systems where flow rate is critical.

Ultimately, a fully lined ball valve is an engineered solution for safely controlling the most demanding fluids.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Complete Fluoropolymer Lining | Total isolation from corrosive media, process purity |

| Full Port Design | Unrestricted flow, minimal pressure drop |

| Two-Piece Bolted Body | Easy maintenance and uniform lining application |

| Integral Ball & Stem | Enhanced structural reliability and durability |

Need a reliable, corrosion-resistant solution for your critical processes?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE and fluoropolymer components, including seals, liners, and custom labware. Our expertise is ideal for the semiconductor, medical, laboratory, and industrial sectors where material integrity is non-negotiable.

We can provide custom-fabricated, fully lined ball valves or components that meet your exact specifications, from prototypes to high-volume orders. Let us help you protect your system and ensure process purity.

Contact KINTEK today to discuss your application and discover the right engineered solution for your needs.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing