The key benefit of a PTFE envelope gasket is its unique two-part construction, which combines the superior chemical resistance of a PTFE outer shell with the mechanical strength and resilience of a separate core material. This design provides an excellent seal in corrosive environments where a solid PTFE gasket might fail under pressure and temperature fluctuations.

A PTFE envelope gasket offers the best of both worlds: the chemically inert surface of PTFE to protect against aggressive media, and the robust mechanical properties of an inner core material to ensure a durable, reliable seal.

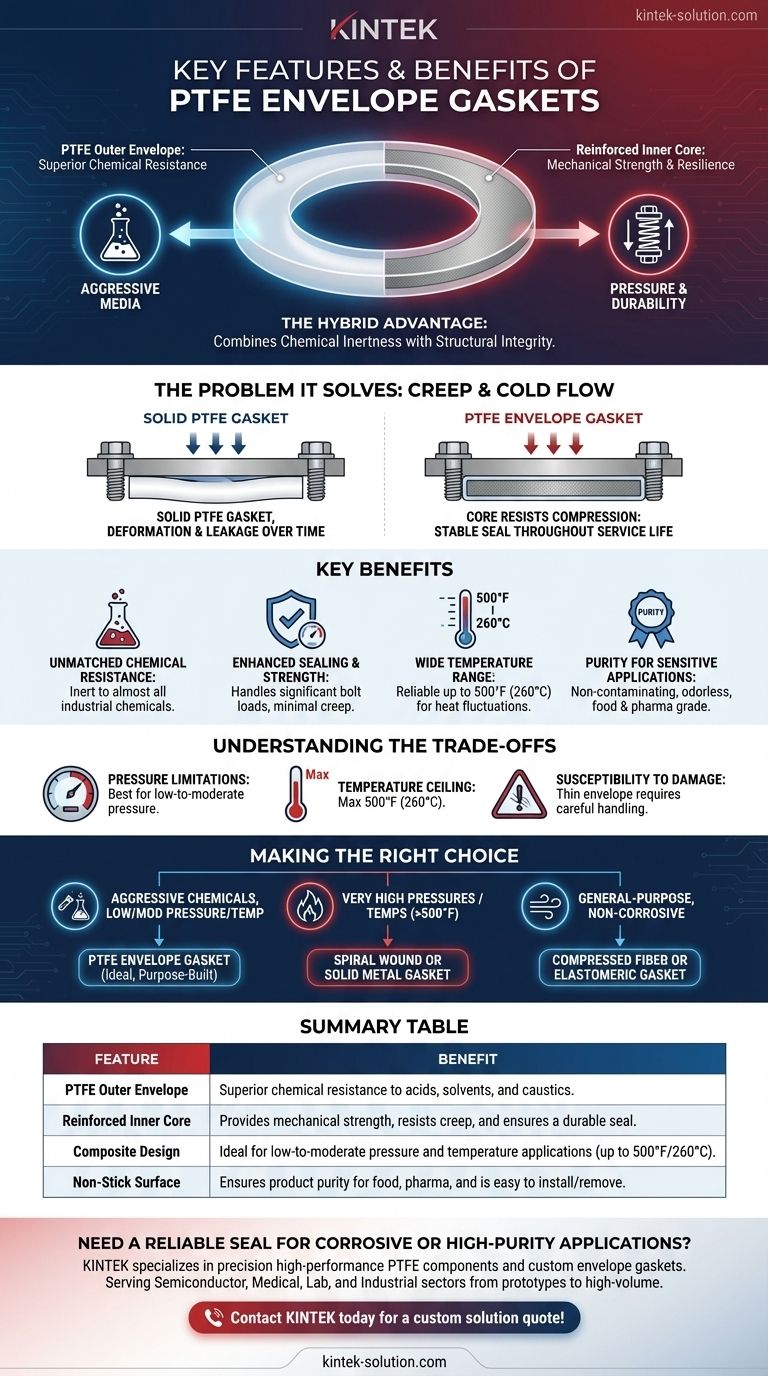

The Core Principle: A Hybrid Design

A PTFE envelope gasket is not a solid piece of PTFE. Understanding its composite structure is the key to understanding its value in demanding industrial applications.

The Two-Part Construction

The gasket consists of an "envelope" or "jacket" made from a thin layer of PTFE (polytetrafluoroethylene). This envelope encloses a separate insert material, which provides the gasket's mechanical properties.

The insert can be made from various materials, such as compressed non-asbestos fiber, rubber, or corrugated metal, depending on the required temperature, pressure, and compressibility.

The Problem It Solves: Creep and Cold Flow

Solid PTFE is exceptionally resistant to chemicals but is a relatively soft material. Under the sustained pressure of a bolted flange, solid PTFE can deform or "creep," leading to a loss of sealing pressure and potential leaks over time.

The internal core material resists this compression, providing the mechanical stability and resilience that the PTFE outer layer lacks. This ensures the gasket maintains a tight seal throughout its service life.

Key Benefits of the Design

This hybrid construction delivers a unique combination of advantages that make it a go-to solution for specific sealing challenges.

Unmatched Chemical Resistance

The entire wetted surface of the gasket is pure PTFE, which is virtually inert to almost all industrial chemicals. This makes it ideal for handling aggressive acids, solvents, and caustics that would degrade other sealing materials.

Enhanced Sealing and Strength

The core material allows the gasket to handle significant bolt loads without being crushed. This provides excellent compressibility to conform to flange surfaces while offering minimal creep relaxation, ensuring a long-term, leak-free seal.

Wide Operating Temperature Range

PTFE envelope gaskets can perform reliably across a broad temperature spectrum, typically up to 500°F (260°C). This makes them suitable for processes involving significant heat fluctuations.

Purity for Sensitive Applications

Because PTFE is non-contaminating, odorless, and has a non-stick surface, these gaskets are an excellent choice for the food, beverage, and pharmaceutical industries. They prevent process media from adhering to the gasket and ensure product purity.

Durability and Ease of Use

The robust design is durable and reduces the need for frequent replacements. The non-stick properties also facilitate easier installation and, more importantly, clean removal from flange surfaces without scraping.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are a specialized solution. Understanding their limitations is critical for proper application.

Pressure Limitations

While they handle high bolt-loading well, they are not designed for the extreme system pressures that metallic or spiral wound gaskets can withstand. They are best suited for low-to-moderate pressure applications.

Temperature Ceiling

The operational limit of around 500°F (260°C) is a hard ceiling. Applications involving higher temperatures require materials like graphite or specialized metallic gaskets.

Susceptibility to Damage

The PTFE envelope is relatively thin. Improper handling during installation or use on damaged or rough flange surfaces can scratch or puncture the envelope, creating a direct leak path and compromising its chemical resistance.

Making the Right Choice for Your Goal

Select your gasket based on the most critical demand of your application.

- If your primary focus is sealing aggressive chemicals in low-to-moderate pressure and temperature systems: The PTFE envelope gasket is the ideal, purpose-built solution.

- If your primary focus is managing very high pressures or temperatures (above 500°F / 260°C): You should specify a spiral wound or solid metal gasket.

- If your primary focus is a general-purpose, non-corrosive application: A more cost-effective compressed fiber or standard elastomeric gasket is likely sufficient.

Ultimately, the PTFE envelope gasket solves the critical challenge of creating a mechanically stable seal in a chemically hostile environment.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Outer Envelope | Superior chemical resistance to acids, solvents, and caustics. |

| Reinforced Inner Core | Provides mechanical strength, resists creep, and ensures a durable seal. |

| Composite Design | Ideal for low-to-moderate pressure and temperature applications (up to 500°F/260°C). |

| Non-Stick Surface | Ensures product purity for food, pharma, and is easy to install/remove. |

Need a reliable seal for corrosive or high-purity applications?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom envelope gaskets. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Our expertise ensures your gaskets provide the perfect balance of chemical inertness and mechanical integrity. Let us help you solve your most challenging sealing problems.

Contact KINTEK today for a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance