The key design features of PTFE bushings stem from the material's unique molecular structure, granting them inherent self-lubrication, an exceptionally low coefficient of friction, and broad resistance to both extreme temperatures and chemical attack. These characteristics allow them to operate without external lubricants in demanding conditions where other materials would quickly fail.

The core value of a PTFE bushing isn't just one feature, but how its combined properties create a maintenance-free, high-performance bearing solution. It excels in challenging environments where traditional lubrication is impractical, undesirable, or impossible.

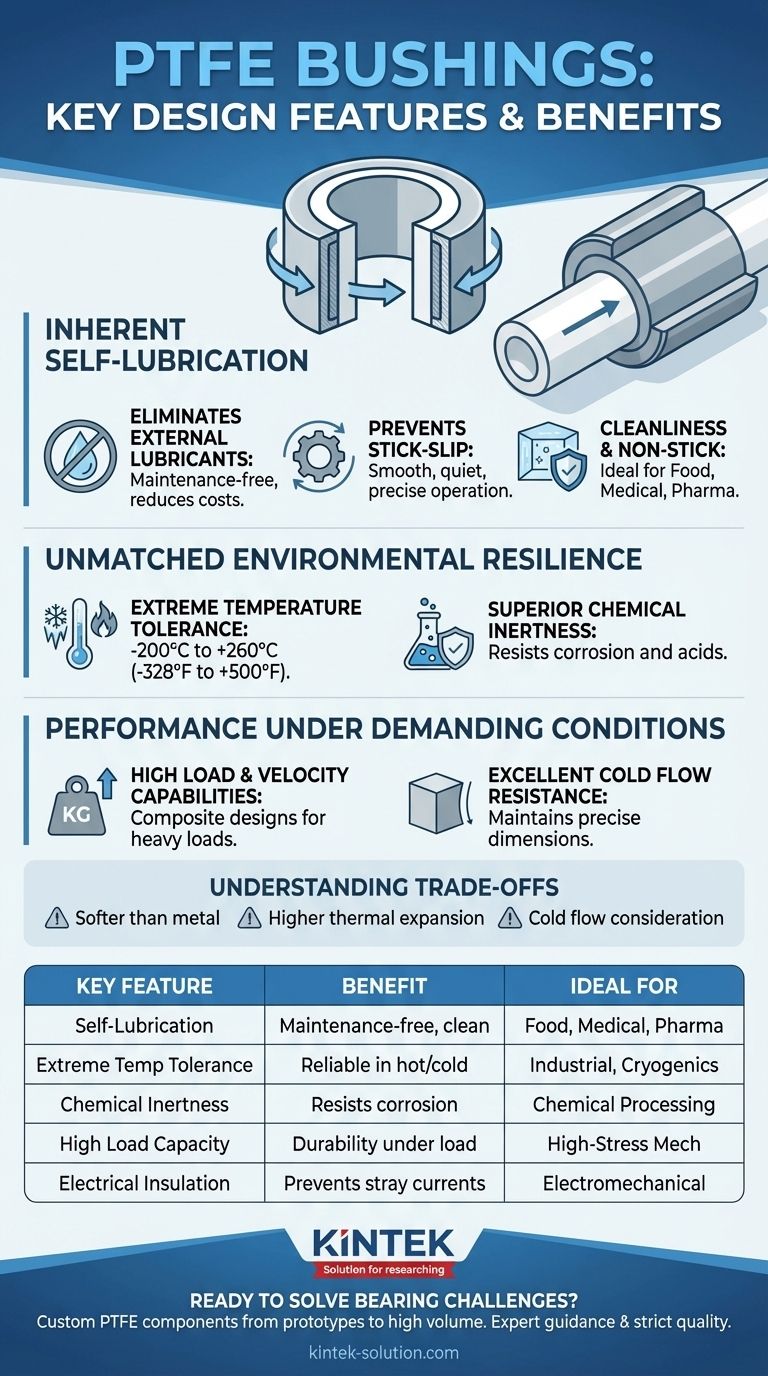

The Core Principle: Inherent Self-Lubrication

The most defining feature of Polytetrafluoroethylene (PTFE) is its ability to function without any external oil or grease. This "dry running" capability is fundamental to its design and application.

Eliminating External Lubricants

PTFE has one of the lowest coefficients of friction of any solid material. This property is not an additive or a coating; it is an intrinsic part of the material itself.

This means the bushing is self-lubricating for its entire service life, dramatically reducing maintenance requirements and eliminating the costs associated with purchasing, applying, and disposing of lubricants.

The Impact on Friction and Stick-Slip

The low friction coefficient ensures smooth, quiet operation. Crucially, it prevents "stick-slip," a phenomenon of jerking motion at low speeds that occurs when static friction is significantly higher than dynamic friction.

PTFE's consistent friction profile allows for precise and repeatable movement, which is critical in sensitive machinery.

Benefits for Maintenance and Cleanliness

Because no external lubricants are needed, PTFE bushings do not attract dust, dirt, or other contaminants. This makes them an ideal choice for applications in food processing, medical, and pharmaceutical industries where cleanliness is paramount.

The non-stick surface is also easy to clean and does not support biological growth.

Unmatched Environmental Resilience

PTFE is renowned for its ability to withstand extreme operating conditions that would degrade or destroy metals and other polymers.

Extreme Temperature Tolerance

PTFE bushings maintain their structural integrity and performance characteristics over an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to be used in everything from cryogenic applications to high-temperature industrial processes without becoming brittle or melting.

Superior Chemical Inertness

The material is chemically inert and non-reactive to nearly all industrial chemicals, solvents, and acids.

This makes PTFE bushings the default choice for pumps, valves, and equipment used in the chemical processing industry or any application involving corrosive substances.

Resistance to Moisture and Contaminants

PTFE is hydrophobic, meaning it repels water and resists moisture absorption. This prevents swelling or changes in dimension when operating in humid or submerged environments. Its non-stick nature also provides excellent resistance to contamination buildup.

Performance Under Demanding Conditions

Beyond its environmental resilience, PTFE is engineered to handle significant mechanical stress, combining several key performance properties.

High Load and Velocity Capabilities

While pure PTFE has limitations, specialized composite PTFE bushings (often with a metal backing and a porous bronze interlayer) are designed for high load-carrying capacity and high sliding velocity.

These designs allow the efficiency of PTFE's low friction to reduce heat generation even under heavy loads, extending the application's service life.

Excellent Cold Flow Resistance

Cold flow (or creep) is a material's tendency to deform permanently under a sustained load. PTFE is engineered for excellent resistance to this phenomenon compared to other polymers.

This ensures the bushing maintains its precise dimensions and small operating clearances over time, preventing loss of performance.

Electrical Insulation Properties

PTFE is a superb electrical insulator, a property that is highly valuable in electromechanical applications. It can prevent stray currents from damaging shafts or other system components.

Understanding the Trade-offs

No material is perfect for every situation. Objectively understanding PTFE's limitations is crucial for correct application.

Softer Than Metal

PTFE is a polymer and is inherently softer than metal bushings like bronze or steel. In applications with extremely high point loads or severe abrasive contamination, a harder material may be required.

Higher Thermal Expansion

Compared to metals, PTFE has a higher coefficient of thermal expansion. Designers must account for this by engineering slightly larger clearances to prevent binding as temperatures rise.

Cold Flow is a Consideration

While PTFE has excellent cold flow resistance for a polymer, it is not immune. For static, long-term, high-load applications, its potential to creep must be a key design consideration, unlike with a metallic bearing.

Making the Right Choice for Your Application

Selecting the correct bushing requires matching its features to your primary operational goal.

- If your primary focus is maintenance-free operation in a clean environment: PTFE is the ideal choice due to its self-lubricating, non-toxic, and non-stick properties.

- If your primary focus is reliability in a harsh chemical or temperature environment: PTFE's unmatched chemical inertness and wide temperature range make it superior to almost any other material.

- If your primary focus is high load capacity and low friction: A composite PTFE-lined metal-backed bushing provides the strength of metal with the low-friction surface of PTFE.

Ultimately, choosing a PTFE bushing is a decision to prioritize reliability, cleanliness, and long-term performance in environments where traditional solutions are not viable.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| Self-Lubrication | Maintenance-free, clean operation | Food, medical, pharmaceutical industries |

| Extreme Temperature Tolerance (-200°C to +260°C) | Reliable performance in cryogenic to high-heat environments | Industrial processes, cryogenics |

| Chemical Inertness | Resistance to corrosive substances | Chemical processing, pumps, valves |

| High Load Capacity (composite designs) | Durability under heavy loads | High-stress mechanical applications |

| Electrical Insulation | Prevents damage from stray currents | Electromechanical systems |

Ready to solve your most demanding bearing challenges?

At KINTEK, we specialize in precision PTFE component manufacturing for semiconductor, medical, laboratory, industrial, and other specialized industries. Our PTFE bushings deliver the maintenance-free performance and environmental resilience your applications require.

We provide:

- Custom PTFE bushing fabrication from prototypes to high-volume orders

- Expert guidance on material selection and design optimization

- Components that meet strict cleanliness and performance standards

Contact us today to discuss how our PTFE solutions can enhance your equipment's reliability and reduce maintenance costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability