The primary benefits of expanded PTFE gaskets are their exceptional chemical resistance, broad temperature stability, and a unique ability to maintain a reliable seal over time by resisting creep and conforming to irregular surfaces. This combination makes them a superior choice for demanding industrial applications where other materials would quickly fail.

The core problem with many gasket materials is their tendency to degrade or deform under chemical attack, temperature fluctuations, or sustained pressure. Expanded PTFE overcomes these failure points, providing a highly durable and conformable seal that ensures long-term operational integrity in the most challenging environments.

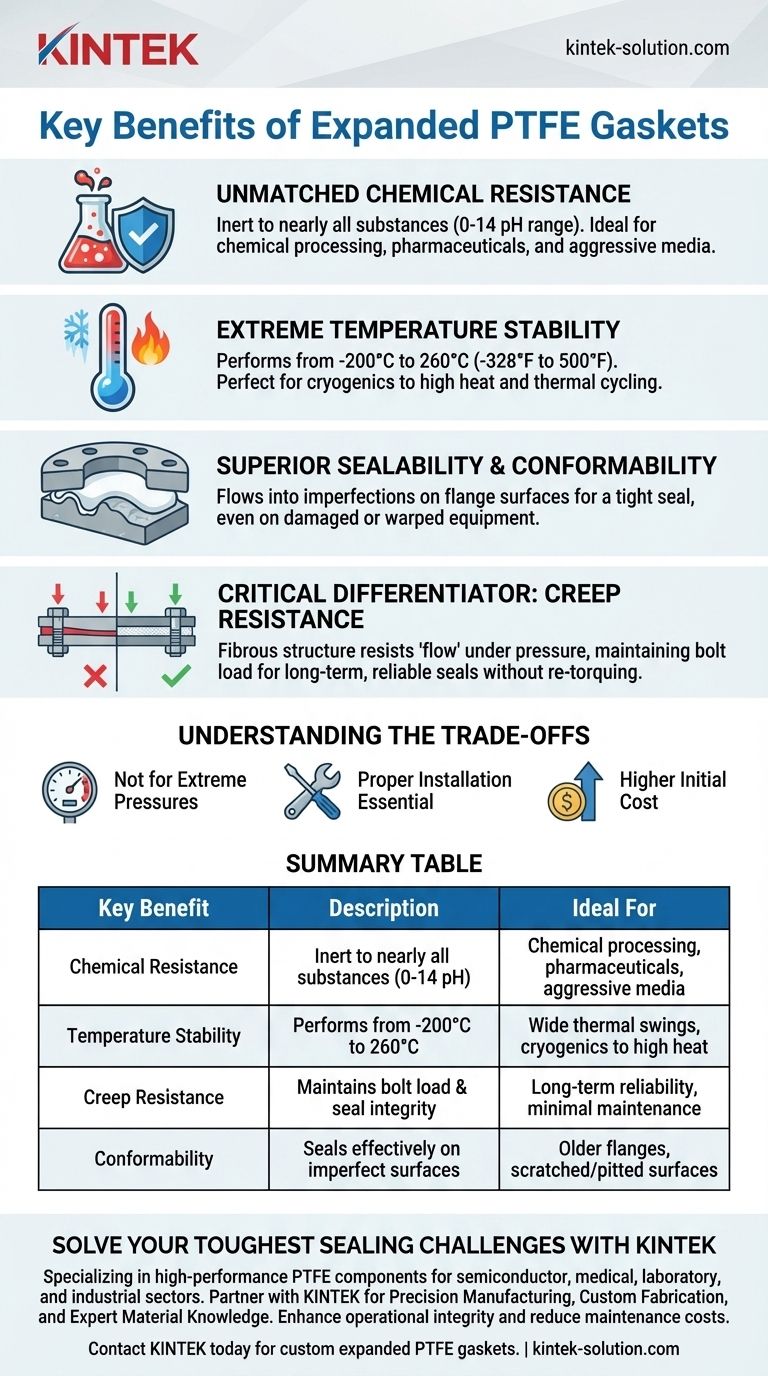

The Core Advantages of Expanded PTFE

Expanded Polytetrafluoroethylene (ePTFE) is not just a standard plastic; it's an engineered material designed to solve specific sealing challenges. Its manufacturing process creates a microporous, fibrous structure that gives it properties far superior to standard PTFE.

Unmatched Chemical Resistance

Expanded PTFE is chemically inert to nearly all substances. It can withstand aggressive acids, bases, solvents, and chemicals across the entire 0-14 pH range.

This makes it an essential material in chemical processing, pharmaceutical, and manufacturing industries where media purity and leak prevention are non-negotiable.

Extreme Temperature Stability

This material maintains its integrity and sealing capability across an exceptionally wide temperature spectrum.

It functions reliably from cryogenic temperatures as low as -200°C (-328°F) up to 260°C (500°F), preventing leaks caused by thermal expansion and contraction cycles.

Superior Sealability on Imperfect Surfaces

Flange surfaces are rarely perfect; they can have scratches, pits, or minor warping. The softness and excellent compressibility of ePTFE allow it to flow into these small imperfections.

This conformability creates an extremely tight, reliable seal where more rigid gasket materials might leave microscopic leak paths.

The Critical Differentiator: Resisting "Creep"

The single most important technical advantage of expanded PTFE is its resistance to creep and cold flow. This directly addresses a common cause of gasket failure.

What is Creep Relaxation?

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. For a gasket, this means the material slowly "flows" or thins out from underneath the compressed flange bolts.

When this happens, the bolt load decreases, the pressure on the seal is lost, and a leak eventually develops. This often requires costly and time-consuming re-torquing of bolts.

How Expanded PTFE Solves the Problem

The expansion process creates a multi-directional, fibrous structure within the PTFE. These fibers interlock and resist the tendency to flow under pressure.

This structural stability means the ePTFE gasket maintains its shape and density, preserving the bolt load and ensuring a consistent, long-term seal without the need for frequent maintenance.

Understanding the Trade-offs

While highly effective, expanded PTFE is a specialized solution. Understanding its limitations is key to using it correctly.

Not for Extreme Pressures

Expanded PTFE excels in low-to-moderate pressure applications. For extremely high-pressure systems, metallic or semi-metallic gaskets may be required to provide the necessary mechanical strength and blow-out resistance.

Proper Installation is Still Essential

Despite its forgiving nature, the gasket's performance depends on proper installation. Achieving the correct bolt torque and following a star-pattern tightening sequence is critical to ensure even compression and a perfect seal.

Higher Initial Cost

As a high-performance engineered material, expanded PTFE typically has a higher upfront cost than standard elastomeric or fiber gaskets. This cost is justified by its extended service life, reduced downtime, and enhanced safety in critical applications.

Making the Right Choice for Your Application

Selecting the correct gasket is about matching the material to the operational demand.

- If your primary focus is sealing aggressive chemicals: Expanded PTFE's near-universal chemical inertness makes it the safest and most reliable choice.

- If your primary focus is handling wide temperature swings: Its stability from cryogenic to high heat ensures a continuous, leak-free seal where other materials would become brittle or degrade.

- If your primary focus is sealing older or damaged flanges: Its exceptional conformability can create a tight seal that compensates for surface imperfections.

- If your primary focus is long-term reliability and minimal maintenance: Its superior resistance to creep ensures the seal holds without requiring frequent re-torquing of bolts.

By leveraging its unique properties, you can specify expanded PTFE with confidence to solve your most difficult sealing challenges.

Summary Table:

| Key Benefit | Description | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to nearly all substances (0-14 pH range) | Chemical processing, pharmaceuticals, aggressive media |

| Temperature Stability | Performs from -200°C to 260°C (-328°F to 500°F) | Applications with wide thermal swings, cryogenics to high heat |

| Creep Resistance | Maintains bolt load and seal integrity over time | Long-term reliability, minimal maintenance applications |

| Conformability | Seals effectively on imperfect or damaged surfaces | Older flanges, scratched or pitted surfaces |

Solve Your Toughest Sealing Challenges with KINTEK

Are you facing leaks, frequent maintenance, or gasket failures in demanding environments? The unique properties of expanded PTFE are engineered to provide the reliable, long-term sealing solution you need.

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom ePTFE gaskets, for the semiconductor, medical, laboratory, and industrial sectors. We understand that a failed seal can mean costly downtime, safety risks, and compromised product purity.

By partnering with KINTEK, you gain:

- Precision Manufacturing: Components made to exact specifications for a perfect fit and optimal performance.

- Custom Fabrication: From rapid prototypes to high-volume production runs, tailored to your specific application requirements.

- Expert Material Knowledge: Guidance on selecting the right PTFE solution to maximize reliability, safety, and cost-efficiency in your operation.

Let us help you enhance operational integrity and reduce maintenance costs.

Contact KINTEK today to discuss your application requirements and receive a quote for custom expanded PTFE gaskets.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications