The primary benefit of PTFE expansion bellows is their near-universal chemical resistance. Made from one of the most chemically inert polymers known, these components can handle nearly all acids, bases, solvents, and other aggressive materials without degrading, ensuring the integrity and safety of critical piping systems.

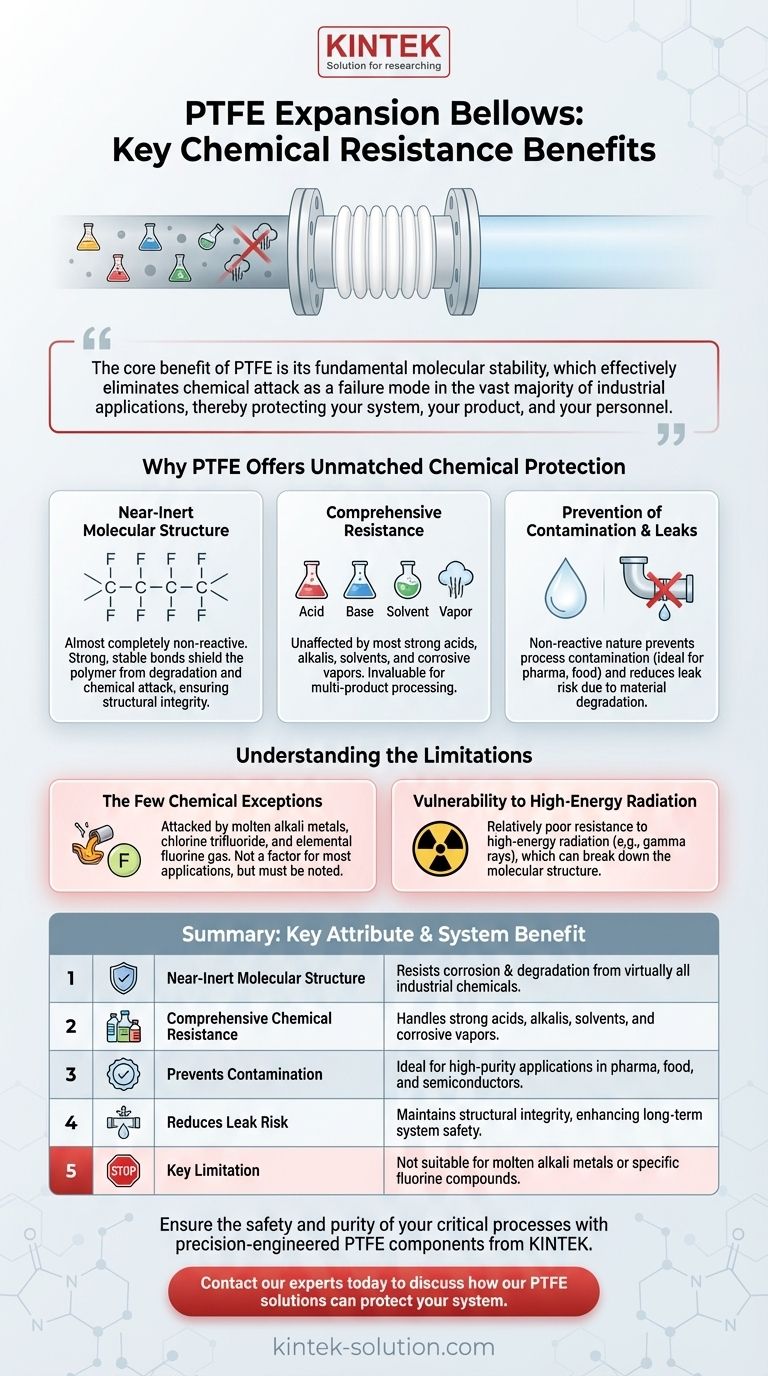

When transporting highly corrosive or reactive media, material failure is not an option. The core benefit of PTFE is its fundamental molecular stability, which effectively eliminates chemical attack as a failure mode in the vast majority of industrial applications, thereby protecting your system, your product, and your personnel.

Why PTFE Offers Unmatched Chemical Protection

The exceptional performance of Polytetrafluoroethylene (PTFE) is not an incidental feature; it is a direct result of its unique molecular composition. Understanding this foundation is key to trusting its application in your systems.

A Near-Inert Molecular Structure

PTFE is prized for being almost completely non-reactive. Its carbon-fluorine bonds are incredibly strong and stable, shielding the polymer from attack by the vast majority of industrial chemicals.

This inertness means the bellow does not corrode, leach, or degrade when exposed to aggressive media. It maintains its structural integrity over long periods.

Comprehensive Resistance Across Chemical Classes

PTFE's resistance is not limited to a specific category of chemicals. It is famously unaffected by most strong acids, alkalis, solvents, and corrosive vapors and gases.

At room temperature, there are virtually no solvents that can dissolve PTFE, a property that makes it invaluable in multi-product chemical processing environments.

Prevention of Contamination and Leaks

Because PTFE does not react with the media it contains, it prevents process contamination. This is critical in high-purity industries like pharmaceuticals, food production, and semiconductors.

This chemical stability directly translates to a reduced risk of leaks and system failures, which are often caused by material degradation over time.

Understanding the Limitations

No material is perfect under all conditions. While PTFE's chemical resistance is extraordinary, a responsible technical assessment requires acknowledging its specific, well-defined limitations.

The Few Chemical Exceptions

PTFE's legendary resistance has a short list of exceptions. It can be attacked by highly reactive substances like molten alkali metals, chlorine trifluoride, and elementary fluorine gas.

For the overwhelming majority of industrial applications, these specific chemicals are not a factor, but their existence must be noted for specialized use cases.

Vulnerability to High-Energy Radiation

PTFE has relatively poor resistance to high-energy radiation, such as gamma rays. This type of radiation can break down the polymer's molecular structure, compromising its physical properties.

This limitation is primarily relevant in nuclear applications or processes involving radiation-based sterilization, where other materials may be more suitable.

Making the Right Choice for Your Application

Selecting the correct expansion bellow is a critical decision for system longevity and safety. PTFE is often the default choice for chemical service, but your specific operational goal is the most important factor.

- If your primary focus is handling a wide variety of aggressive chemicals: PTFE is the safest and most reliable choice due to its near-universal inertness, reducing the need for multiple material types.

- If your primary focus is product purity in food, pharma, or electronics: PTFE's non-reactive and non-adhesive nature ensures the medium remains uncontaminated by the piping component.

- If your system involves molten alkali metals or specific fluorine compounds: You must seek an alternative material, as this is one of the few environments where PTFE is not suitable.

By understanding both its unmatched strengths and its specific limitations, you can confidently specify PTFE to ensure maximum operational integrity and safety.

Summary Table:

| Key Attribute | Benefit for Your System |

|---|---|

| Near-Inert Molecular Structure | Resists corrosion and degradation from virtually all industrial chemicals. |

| Comprehensive Chemical Resistance | Handles strong acids, alkalis, solvents, and corrosive vapors. |

| Prevents Contamination | Ideal for high-purity applications in pharma, food, and semiconductors. |

| Reduces Leak Risk | Maintains structural integrity, enhancing long-term system safety. |

| Key Limitation | Not suitable for molten alkali metals or specific fluorine compounds. |

Ensure the safety and purity of your critical processes with precision-engineered PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, our PTFE expansion bellows, seals, liners, and labware are manufactured to the highest standards of precision and chemical inertness. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can protect your system, your product, and your personnel.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems