The fundamental benefit of expanded PTFE (ePTFE) is its unique microporous structure, which transforms standard PTFE into a remarkably strong, soft, and versatile material. This expansion process unlocks superior performance in sealing, medical implants, and industrial applications by adding exceptional mechanical properties to PTFE's already outstanding chemical and thermal resistance.

The core takeaway is that expanding PTFE doesn't just make it porous; it creates a multidirectionally stable material that resists the "creep" common in standard PTFE. This makes it an elite choice for creating durable, long-lasting seals in chemically aggressive and high-temperature environments.

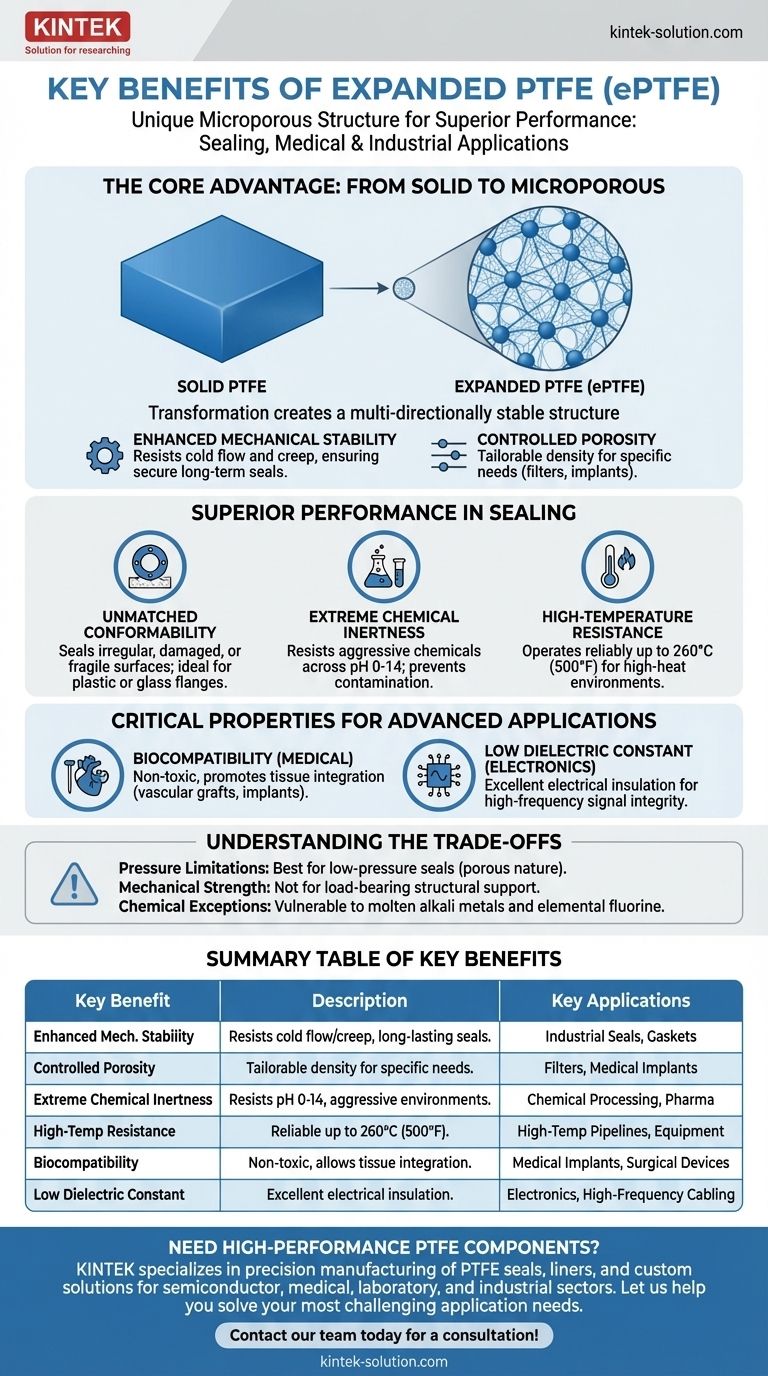

The Core Advantage: From Solid to Microporous

The true value of ePTFE lies in the manufacturing process. By physically stretching solid PTFE under specific conditions, a powerful new material structure is formed.

### What is "Expanded" PTFE?

The expansion process creates a microstructure of solid PTFE nodes interconnected by a web of thin fibrils. This structure is incredibly strong yet contains a significant amount of empty space.

This internal architecture is what gives ePTFE its unique combination of softness and dimensional stability.

### Enhanced Mechanical Stability

Unlike conventional PTFE, which can deform or "flow" under pressure over time, ePTFE is a multi-directionally expanded material.

This structure provides high linear strength and makes it highly resistant to cold flow and creep, ensuring a seal remains tight and secure long after installation.

### Controlled Porosity

The density of ePTFE can be precisely controlled during manufacturing, resulting in low, medium, or high-density variants.

This allows the material to be tailored for specific applications, such as high-performance filters or medical implants where tissue integration is desired.

Superior Performance in Sealing Applications

For industrial sealing, ePTFE is often the definitive solution for challenging environments where other materials fail.

### Unmatched Conformability

ePTFE is exceptionally soft and conformable, allowing it to create a tight seal on irregular, damaged, or uneven flange surfaces.

This property also makes it ideal for sealing fragile flanges made of plastic or glass, where high bolt loads would cause cracking with harder gasket materials.

### Extreme Chemical Inertness

The material maintains PTFE's legendary chemical resistance, sealing aggressive chemicals across the entire pH range of 0-14.

It will not contaminate or discolor the end product, a critical factor in hygienic or high-purity industries. The only common exceptions are molten alkali metals and elemental fluorine.

### High-Temperature Resistance

ePTFE operates reliably at continuous service temperatures up to 260°C (500°F), making it suitable for high-temperature pipelines and processing equipment.

Critical Properties for Advanced Applications

Beyond industrial sealing, the unique properties of ePTFE make it a critical material in the medical and electronics fields.

### Biocompatibility for Medical Devices

ePTFE is non-toxic, non-allergenic, and highly biocompatible, making it a trusted material for medical implants.

Its microporous structure allows human tissue and blood vessels to grow into the material, forming strong connections. This is why it is used for artificial blood vessels, heart patches, and surgical sutures.

### Low Dielectric Constant for Electronics

With a very low dielectric constant, ePTFE is an excellent electrical insulator. This makes it valuable in high-performance wiring, cables, and electronic components where signal integrity is paramount.

### Durability and Environmental Resistance

The material is inherently resistant to UV radiation, making it suitable for outdoor applications without degradation. It is also watertight at low pressures, providing a reliable environmental seal.

Understanding the Trade-offs

While incredibly capable, ePTFE is not a universal solution. Understanding its limitations is key to using it effectively.

### Pressure Limitations

The references specify that ePTFE is "watertight at low pressure." The porous nature that provides its conformability can be a liability in very high-pressure sealing applications, where a solid material may be required.

### Mechanical Strength

While its tensile strength is high for a polymer, it is not a replacement for metal or high-strength composites in load-bearing structural applications. Its value is in sealing, lining, and insulation—not structural support.

### Chemical Exceptions

It is crucial to remember its two primary chemical vulnerabilities: molten alkali metals and elemental fluorine. In applications involving these substances, an alternative material is necessary.

Making the Right Choice for Your Goal

To determine if ePTFE is the correct material, align its primary benefits with the central challenge of your project.

- If your primary focus is aggressive chemical sealing: ePTFE's conformability and superior resistance to creep make it the ideal choice for creating durable, leak-free seals, especially on imperfect or fragile flanges.

- If your primary focus is medical biocompatibility: The microporous, inert, and non-toxic structure of ePTFE is a proven, safe choice for implants and devices requiring tissue integration.

- If your primary focus is high-frequency electronics: The material's exceptionally low dielectric constant provides the excellent electrical insulation needed to protect signal integrity.

By understanding its unique structural properties, you can leverage expanded PTFE to solve complex engineering challenges that other materials simply cannot address.

Summary Table:

| Key Benefit | Description | Key Applications |

|---|---|---|

| Enhanced Mechanical Stability | Resists cold flow and creep, providing long-lasting seals. | Industrial Seals, Gaskets |

| Controlled Porosity | Tailorable density for specific performance needs. | Filters, Medical Implants |

| Extreme Chemical Inertness | Resists chemicals across pH 0-14, ideal for aggressive environments. | Chemical Processing, Pharma |

| High-Temperature Resistance | Operates reliably up to 260°C (500°F). | High-Temp Pipelines, Equipment |

| Biocompatibility | Non-toxic and allows tissue integration. | Medical Implants, Surgical Devices |

| Low Dielectric Constant | Excellent electrical insulation for signal integrity. | Electronics, High-Frequency Cabling |

Need high-performance PTFE components tailored to your specific requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in materials like expanded PTFE ensures you get durable, chemically resistant, and reliable solutions—from prototypes to high-volume production.

Let us help you solve your most challenging application needs. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability