In sanitary applications, PTFE/Teflon tri-clamp gaskets are prized for their exceptional chemical resistance, broad temperature stability, and superior purity. Their non-stick surface minimizes product adhesion and contamination, while their machined construction ensures dimensional accuracy for a precise fit in critical process lines.

At its core, the decision to use a PTFE gasket is a decision for uncompromising performance in extreme conditions. It is the material of choice when chemical inertness, temperature resilience, and high purity are non-negotiable, but this performance comes with specific installation and sealing considerations due to its rigidity.

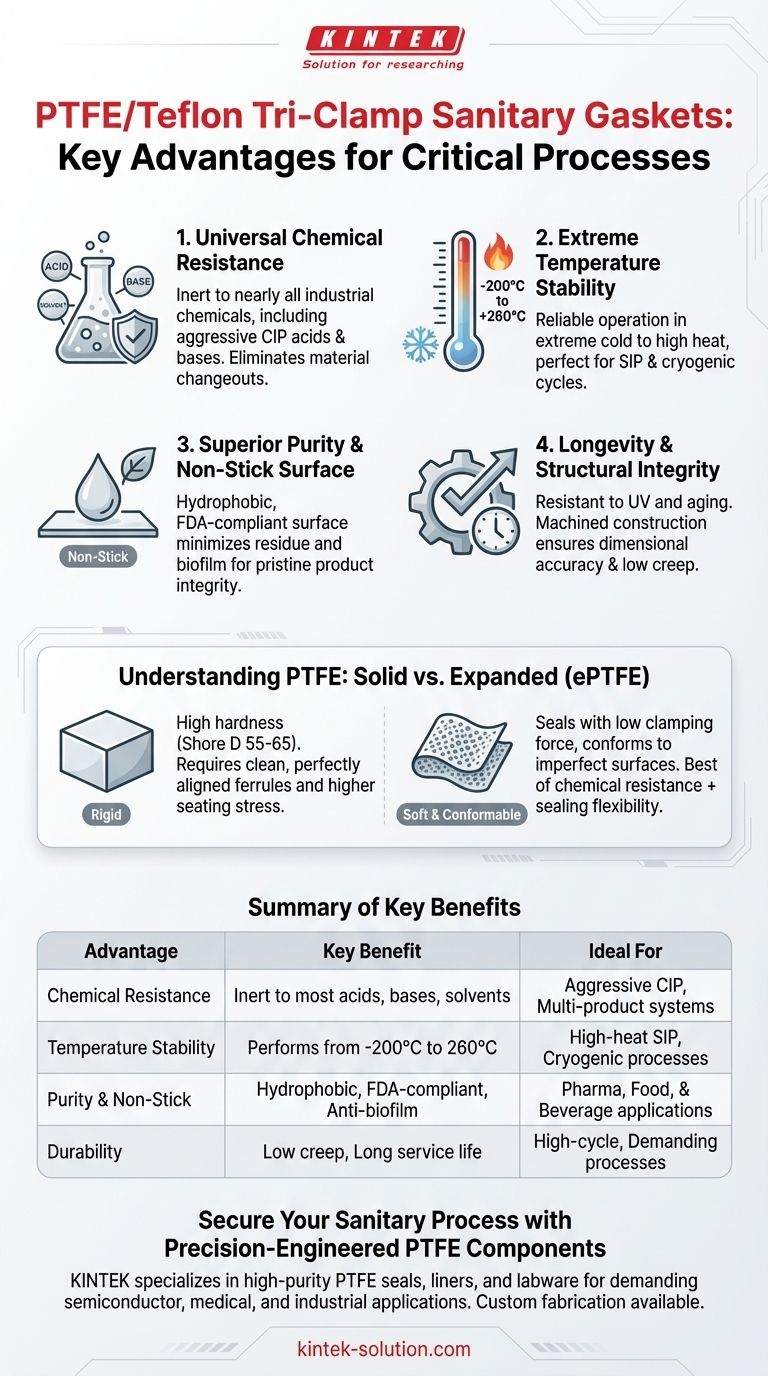

The Core Advantages of PTFE in Sanitary Systems

Understanding why PTFE is so prevalent in pharmaceutical, food, and beverage industries requires looking at how its unique properties solve critical processing challenges.

### Universal Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, and solvents. This makes it an ideal sealing material in systems where a variety of products are processed or where harsh Clean-in-Place (CIP) chemicals are used.

This universal compatibility eliminates the need to change gasket materials for different process runs, simplifying inventory and reducing the risk of material failure from chemical attack.

### Extreme Temperature Stability

PTFE gaskets operate reliably across an exceptionally wide temperature range, typically from cryogenic temperatures of -200°C (-328°F) up to 260°C (500°F).

This thermal stability makes them perfectly suited for processes that involve extreme cold or high heat, such as high-temperature sterilization cycles like Steam-in-Place (SIP).

### Superior Purity and Non-Stick Surface

For any sanitary application, preventing contamination is paramount. PTFE is inherently hydrophobic (water-repelling) and has an extremely low coefficient of friction, creating a non-stick surface.

This property prevents process media from sticking to the gasket, which in turn minimizes the potential for residue buildup and biofilm formation. Most PTFE gaskets are also FDA-compliant, ensuring they are safe for direct contact with food and pharmaceutical products.

### Longevity and Structural Integrity

PTFE is a highly durable material that does not degrade with age or exposure to UV light. Being machined from solid billets gives it excellent dimensional stability.

Furthermore, certain types like expanded PTFE (ePTFE) offer very low creep relaxation, meaning the gasket maintains its shape and sealing force over time, even under repeated compression cycles.

Understanding the Trade-offs

While its advantages are significant, PTFE is not a universal solution. Its primary trade-off is its mechanical nature compared to more flexible elastomers like silicone or EPDM.

### The Challenge of Rigidity

Standard solid PTFE is a relatively hard plastic, often with a Shore D hardness of 55-65. It is not a soft, compressible rubber.

This rigidity means it is less forgiving of flange misalignment or surface imperfections. A proper seal with a solid PTFE gasket requires clean, perfectly aligned, and smooth tri-clamp ferrules.

### Higher Seating Stress Required

Because it is not as compressible as an elastomer, a solid PTFE gasket requires more clamping force to achieve a leak-proof seal.

This can lead to over-tightening, which can damage the gasket or the tri-clamp ferrule itself. Proper installation torque is critical.

### Standard PTFE vs. Expanded PTFE (ePTFE)

It's crucial to distinguish between solid PTFE and expanded PTFE. While solid PTFE is rigid, ePTFE is a soft, highly conformable material created by expanding PTFE.

ePTFE is designed specifically to overcome the rigidity of solid PTFE. It seals effectively with low clamping force and can conform to uneven or scratched surfaces, offering the chemical benefits of PTFE with the sealing flexibility of an elastomer.

Making the Right Choice for Your Goal

Selecting the right gasket material depends entirely on the specific demands of your process.

- If your primary focus is extreme chemical compatibility: PTFE is the unparalleled choice, offering near-universal resistance where elastomers would fail.

- If your primary focus is high-temperature processes: PTFE's stability makes it ideal for applications involving high-heat sterilization like SIP.

- If your primary focus is absolute product purity: The non-stick, low-porosity surface of PTFE is your best defense against residue and contamination.

- If your primary focus is sealing imperfect flanges or ease of installation: Consider a more forgiving elastomer like EPDM or silicone, or specify expanded PTFE (ePTFE) to get the best of both worlds.

Ultimately, choosing PTFE is an investment in process security for your most demanding applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to nearly all acids, bases, and solvents | Systems using aggressive CIP chemicals |

| Temperature Stability | Performs from -200°C to 260°C | High-heat SIP sterilization & cryogenic processes |

| Purity & Non-Stick | Hydrophobic, FDA-compliant, prevents biofilm | Pharmaceutical, food, and beverage applications |

| Durability | Low creep relaxation, long service life | High-cycle processes requiring reliability |

Secure Your Sanitary Process with Precision-Engineered PTFE Components

For demanding applications in semiconductor, medical, laboratory, and industrial settings, the right gasket is critical. KINTEK specializes in manufacturing high-purity PTFE components—including seals, liners, and labware—that deliver uncompromising chemical resistance and thermal stability.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific system requirements.

Ready to enhance your process integrity? Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability