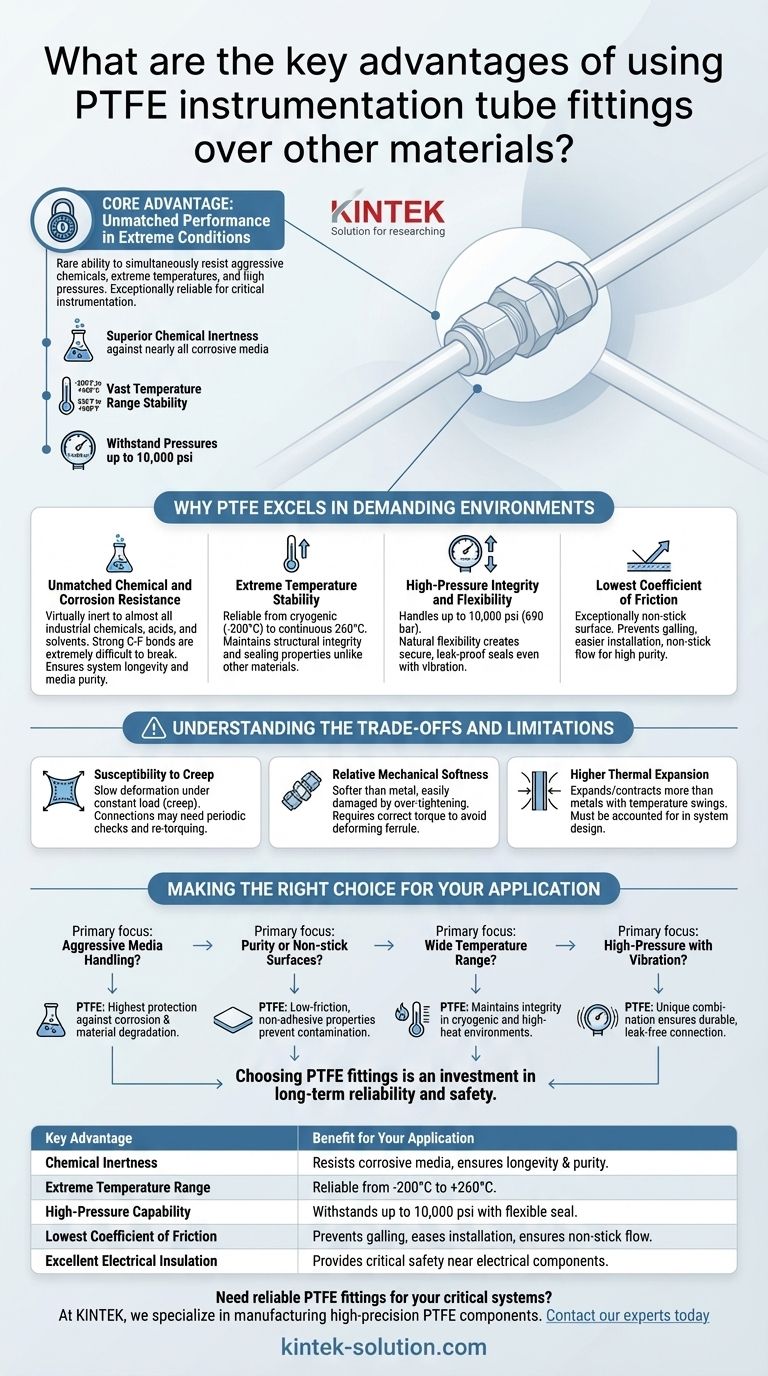

The key advantages of PTFE instrumentation tube fittings stem from a unique combination of properties that make them exceptionally reliable in extreme conditions. They offer superior chemical inertness against nearly all corrosive media, maintain stability across a vast temperature range from -200°C to +260°C (-328°F to +500°F), and can withstand pressures up to 10,000 psi. This makes PTFE the material of choice for demanding applications where other materials would quickly fail.

While many materials excel in one specific area, PTFE's core advantage is its rare ability to simultaneously resist aggressive chemicals, extreme temperatures, and high pressures. This makes it a uniquely reliable choice for critical instrumentation where system integrity and safety are paramount.

Why PTFE Excels in Demanding Environments

To understand why PTFE is specified for critical systems, we must look beyond a single feature and see how its properties work together. This combination provides a level of performance that is difficult to achieve with other polymers or even specialized metals.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. The strong carbon-fluorine bonds that make up its structure are extremely difficult to break.

This means the fitting will not corrode, degrade, or contaminate the process media, ensuring both system longevity and media purity.

Extreme Temperature Stability

PTFE fittings perform reliably across an exceptionally wide temperature spectrum, from cryogenic applications (-200°C / -328°F) up to continuous service at 260°C (500°F).

Unlike other materials that become brittle at low temperatures or soften at high temperatures, PTFE maintains its structural integrity and sealing properties.

High-Pressure Integrity and Flexibility

Despite being a polymer, PTFE can handle significant pressure, with ratings often reaching 10,000 psi (690 bar).

This high-pressure capability is combined with a natural flexibility that helps create a secure, leak-proof seal, even in systems with minor vibrations or tubing misalignments.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material, giving it an exceptionally non-stick surface.

In instrumentation fittings, this property prevents galling during assembly, allows for easier installation, and ensures that process media does not adhere to or clog the fitting. This is critical for applications requiring high purity or smooth flow.

Excellent Durability and Insulation

The material is highly resistant to weathering and UV radiation, making it suitable for long-term outdoor installations.

Additionally, PTFE is an outstanding electrical insulator, which is a critical safety feature in applications where instrumentation lines may be near electrical components.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Being a trusted advisor means acknowledging where PTFE may not be the optimal choice. Its unique strengths come with inherent trade-offs that must be considered during the design phase.

Susceptibility to Creep

Like many polymers, PTFE can be subject to "creep," which is a slow deformation over time when under a constant load (like a tightened nut).

This means that connections may need to be periodically checked and re-torqued, especially in high-temperature or high-pressure applications.

Relative Mechanical Softness

Compared to metal fittings, PTFE is a much softer material. It can be easily damaged by over-tightening, which can deform the ferrule and compromise the seal.

Care must be taken during installation to apply the correct torque and avoid scratching or galling the sealing surfaces with contaminated tools.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. In systems with wide temperature swings, the fitting may expand and contract more than the metal tubing it's connected to.

This must be accounted for in the system design to prevent leaks from developing as the system cycles through different temperatures.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision based on the specific demands of your system. Use the following guidelines to determine if it aligns with your primary goal.

- If your primary focus is aggressive media handling: PTFE's chemical inertness provides the highest level of protection against corrosion and material degradation.

- If your primary focus is purity or non-stick surfaces: Its low-friction, non-adhesive properties prevent contamination and ensure smooth flow in sensitive laboratory or food-grade applications.

- If your primary focus is a wide temperature range: PTFE maintains its integrity and sealing capability in both cryogenic and high-heat environments where most other polymers would fail.

- If your primary focus is high-pressure sealing with vibration: Its unique combination of pressure resistance and flexibility ensures a durable, leak-free connection.

Ultimately, choosing PTFE fittings is an investment in the long-term reliability and safety of your most critical instrumentation.

Summary Table:

| Key Advantage | Benefit for Your Application |

|---|---|

| Chemical Inertness | Resists virtually all corrosive media, ensuring system longevity and media purity. |

| Extreme Temperature Range | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| High-Pressure Capability | Withstands pressures up to 10,000 psi (690 bar) with a secure, flexible seal. |

| Lowest Coefficient of Friction | Prevents galling, eases installation, and ensures non-stick, clog-free flow. |

| Excellent Electrical Insulation | Provides critical safety in applications near electrical components. |

Need reliable PTFE fittings for your critical systems?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your instrumentation benefits from PTFE's superior chemical resistance, temperature stability, and pressure integrity.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit for your demanding application requirements.

Contact our experts today to discuss your specific needs and ensure long-term reliability for your most critical systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments