The key advantages of using PTFE in sealing applications are its extreme temperature stability, near-universal chemical inertness, and an exceptionally low coefficient of friction. These properties stem directly from its unique molecular structure, allowing it to perform reliably in demanding environments where most other polymer seals would quickly fail.

PTFE is not just another plastic; it's a high-performance fluoropolymer engineered for extremes. Its true value lies in its ability to maintain its core sealing properties—thermal, chemical, and frictional—across an incredibly wide operational window, ensuring reliability in the most critical applications.

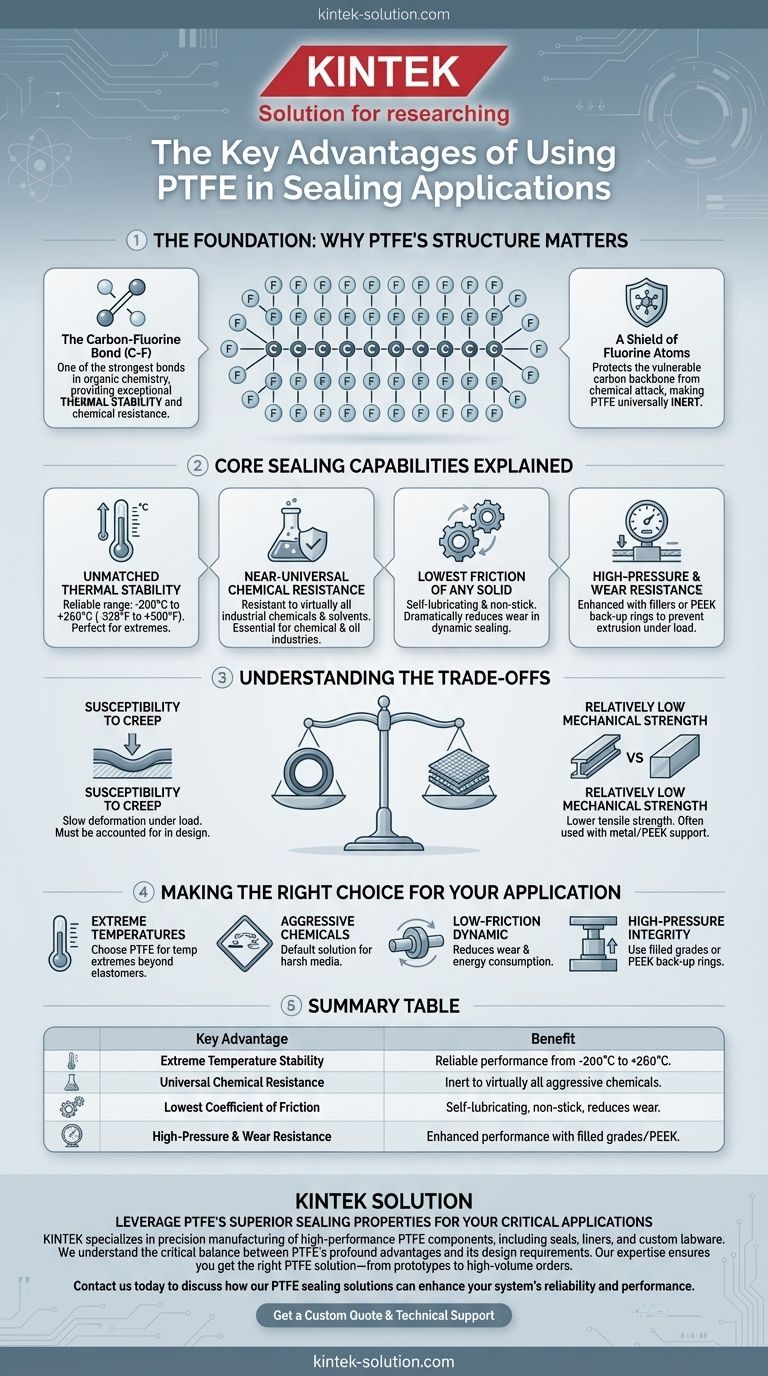

The Foundation: Why PTFE's Structure Matters

To understand PTFE's advantages, we must first look at its molecular makeup. This is the source of its remarkable sealing capabilities.

The Carbon-Fluorine Bond

At its core, PTFE consists of a long chain of carbon atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

This inherent strength gives the material its exceptional thermal stability and contributes significantly to its chemical resistance.

A Shield of Fluorine Atoms

The carbon chain is completely sheathed by a dense layer of fluorine atoms. This fluorine "shield" effectively protects the vulnerable carbon backbone from chemical attack.

This structure is what makes PTFE almost universally inert, preventing it from reacting with even the most aggressive acids, bases, and solvents.

Core Sealing Capabilities Explained

The molecular structure translates directly into tangible performance benefits that make PTFE a premier choice for sealing.

Unmatched Thermal Stability

PTFE seals operate effectively across an enormous temperature range, typically from -200°C to +260°C (-328°F to +500°F).

It provides a reliable solution for applications that are too cold or too hot for standard elastomeric seals, but do not require the expense and rigidity of metal seals.

Near-Universal Chemical Resistance

Due to its inert molecular structure, PTFE is resistant to virtually all industrial chemicals and solvents.

This makes it indispensable in industries like chemical processing, oil and gas, and aerospace, where seals are exposed to aggressive or corrosive media.

The Lowest Friction of Any Solid

PTFE has the lowest coefficient of friction of any known solid material. This gives it self-lubricating and non-stick properties.

In dynamic sealing applications, this dramatically reduces wear, prevents stick-slip issues, and allows for continuous dry-running operation without external lubrication.

High-Pressure and Wear Resistance

While inherently a softer material, PTFE exhibits excellent durability and wear resistance in sealing applications.

Its performance under high pressure can be significantly enhanced by combining it with fillers or using it in conjunction with PEEK back-up rings, which prevent the seal from extruding under load.

Understanding the Trade-offs

No material is perfect. While PTFE's properties are exceptional, an objective analysis requires understanding its limitations.

Susceptibility to Creep

PTFE is susceptible to "creep" or cold flow, meaning it can deform slowly over time when subjected to a constant load.

This must be accounted for in seal design, especially in static applications where consistent pressure is critical over long periods.

The Need for Reinforcement

In its pure (virgin) form, PTFE's mechanical properties can be insufficient for high-load or high-wear dynamic applications.

This is why filled grades of PTFE (e.g., glass-filled, carbon-filled) are common. Fillers enhance wear resistance, reduce creep, and improve dimensional stability.

Relatively Low Mechanical Strength

Compared to metals or high-strength polymers like PEEK, PTFE has lower tensile strength and hardness.

This is why it is often used for the sealing element itself, while stronger materials like metal or PEEK provide structural support in the seal housing or as back-up rings.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is extreme temperature stability: PTFE is the clear choice for applications that exceed the limits of elastomers but don't warrant metal seals.

- If your primary focus is aggressive chemical compatibility: PTFE's inertness makes it the default solution for sealing harsh media in chemical or processing industries.

- If your primary focus is low-friction dynamic sealing: PTFE's self-lubricating properties reduce wear, lower energy consumption, and ensure smooth operation.

- If your primary focus is high-pressure integrity: Use PTFE, but ensure you specify a filled grade or design with PEEK back-up rings to prevent extrusion and creep.

Ultimately, leveraging PTFE effectively means understanding its profound strengths while designing to mitigate its inherent material trade-offs.

Summary Table:

| Key Advantage | Benefit for Sealing Applications |

|---|---|

| Extreme Temperature Stability | Reliable performance from -200°C to +260°C (-328°F to +500°F). |

| Universal Chemical Resistance | Inert to virtually all aggressive acids, bases, and solvents. |

| Lowest Coefficient of Friction | Self-lubricating, non-stick, reduces wear in dynamic applications. |

| High-Pressure & Wear Resistance | Enhanced performance with filled grades or PEEK back-up rings. |

Leverage PTFE's Superior Sealing Properties for Your Critical Applications

Do you face challenges with extreme temperatures, aggressive chemicals, or demanding dynamic sealing? KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom labware. We understand the critical balance between PTFE's profound advantages and its design requirements.

Our expertise ensures you get the right PTFE solution—whether a standard seal or a custom-fabricated component designed to mitigate creep and enhance pressure integrity. We serve the semiconductor, medical, laboratory, and industrial sectors with prototypes and high-volume orders.

Contact us today to discuss how our PTFE sealing solutions can enhance your system's reliability and performance.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance