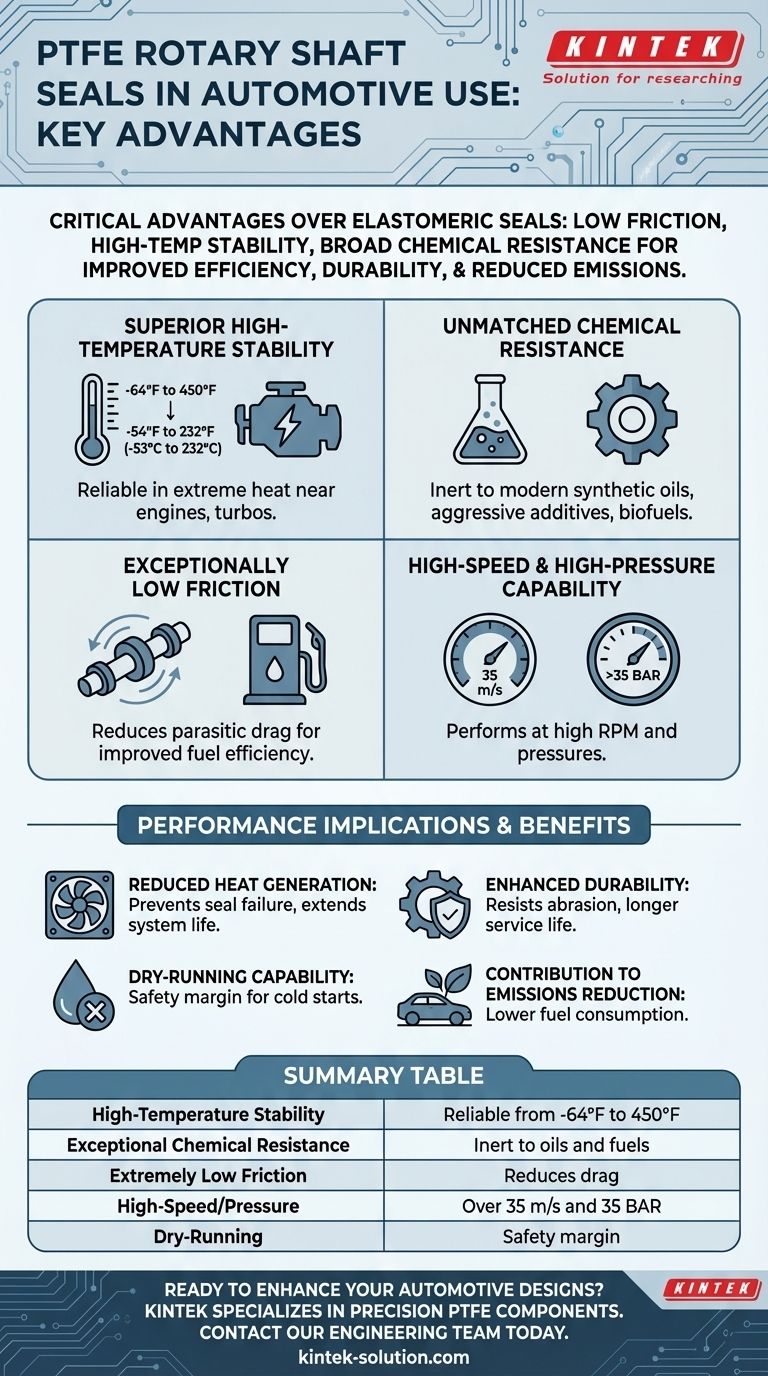

In automotive applications, PTFE rotary shaft seals provide critical advantages over traditional elastomeric seals, primarily due to their exceptionally low friction, superior high-temperature stability, and broad chemical resistance. These properties allow them to operate reliably at higher rotational speeds and pressures, directly contributing to improved vehicle efficiency, durability, and reduced emissions.

The core reason to choose PTFE seals is for high-performance applications where traditional rubber seals would fail. They are an engineering solution designed to withstand the extreme heat, aggressive fluids, and high speeds of modern engines and transmissions, ensuring reliability where it matters most.

Why PTFE Excels in Demanding Automotive Environments

The move towards PTFE (polytetrafluoroethylene) is a direct response to the increasing demands of modern vehicle engineering. As engines become more powerful and efficient, the operating conditions for components like seals become more severe.

Superior High-Temperature Stability

PTFE seals maintain their integrity and sealing capability across an extremely wide temperature range, typically from -64°F to 450°F (-53°C to 232°C). This makes them essential for sealing components in or near the engine block, turbochargers, and high-performance transmissions where conventional rubber seals would degrade and fail.

Unmatched Chemical Resistance

Modern automotive systems use a complex mix of synthetic lubricants, aggressive additives, and biofuels. PTFE is chemically inert, meaning it will not swell, soften, or break down when exposed to these fluids, ensuring a reliable seal for the life of the component.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property significantly reduces the parasitic drag on rotating shafts, like an engine's crankshaft. Less drag means less wasted energy, which translates directly to improved fuel efficiency.

High-Speed and High-Pressure Capability

The material's low friction and durability allow PTFE seals to perform at very high surface speeds (up to 35 m/s) and pressures (exceeding 35 BAR). This is a critical advantage for high-RPM performance engines and advanced transmission systems where other materials would quickly overheat and wear out.

Understanding the Performance Implications

The inherent properties of PTFE lead to tangible benefits in vehicle performance, reliability, and maintenance. Understanding these implications is key to appreciating their value.

Reduced Heat Generation

Because PTFE seals generate significantly less friction, they also generate less heat. This prevents premature hardening or cracking of the seal lip and reduces thermal stress on the shaft and surrounding components, extending the entire system's operational life.

Enhanced Durability and Longevity

The material's resistance to abrasion and its ability to glide smoothly over rotating shafts mean PTFE seals last longer. This superior durability reduces the need for costly maintenance and prevents leaks that could lead to catastrophic component failure.

Dry-Running Capability

A key feature of PTFE seals is their ability to function effectively even with minimal or no lubrication. While most automotive applications are lubricated, this property provides an essential margin of safety during cold starts or momentary oil starvation events.

Contribution to Emissions Reduction

The push for lower vehicle emissions is a primary driver of automotive design. By reducing frictional losses within the engine and drivetrain, PTFE seals help improve overall efficiency, leading to lower fuel consumption and a corresponding reduction in CO2 emissions.

Making the Right Choice for Your Application

Selecting the correct seal material is not just about preventing leaks; it's about optimizing the performance and reliability of the entire system.

- If your primary focus is high-performance and high-RPM applications: PTFE's unmatched speed and temperature capabilities are essential for reliability in racing or turbocharged engines.

- If your primary focus is longevity in harsh chemical environments: PTFE's chemical inertness ensures seal integrity when using modern synthetic oils and aggressive fuel blends.

- If your primary focus is maximizing efficiency and meeting emissions targets: The low parasitic drag from PTFE seals provides a measurable advantage in achieving fuel economy goals.

Ultimately, PTFE rotary shaft seals are the definitive choice for critical, high-stress sealing points in modern automotive engineering.

Summary Table:

| Key Advantage | Benefit for Automotive Applications |

|---|---|

| High-Temperature Stability | Reliable sealing from -64°F to 450°F, ideal for engines and turbos. |

| Exceptional Chemical Resistance | Inert to modern oils and fuels, ensuring long-term seal integrity. |

| Extremely Low Friction | Reduces parasitic drag, directly improving fuel efficiency. |

| High-Speed/Pressure Capability | Operates at speeds over 35 m/s and pressures exceeding 35 BAR. |

| Dry-Running Capability | Provides a safety margin during cold starts or oil starvation. |

Ready to enhance your automotive designs with high-performance PTFE seals?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom rotary shaft seals for the automotive, semiconductor, medical, and industrial sectors. Our expertise ensures your seals deliver the durability, efficiency, and reliability your high-performance applications demand.

Contact our engineering team today to discuss your custom fabrication needs, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability