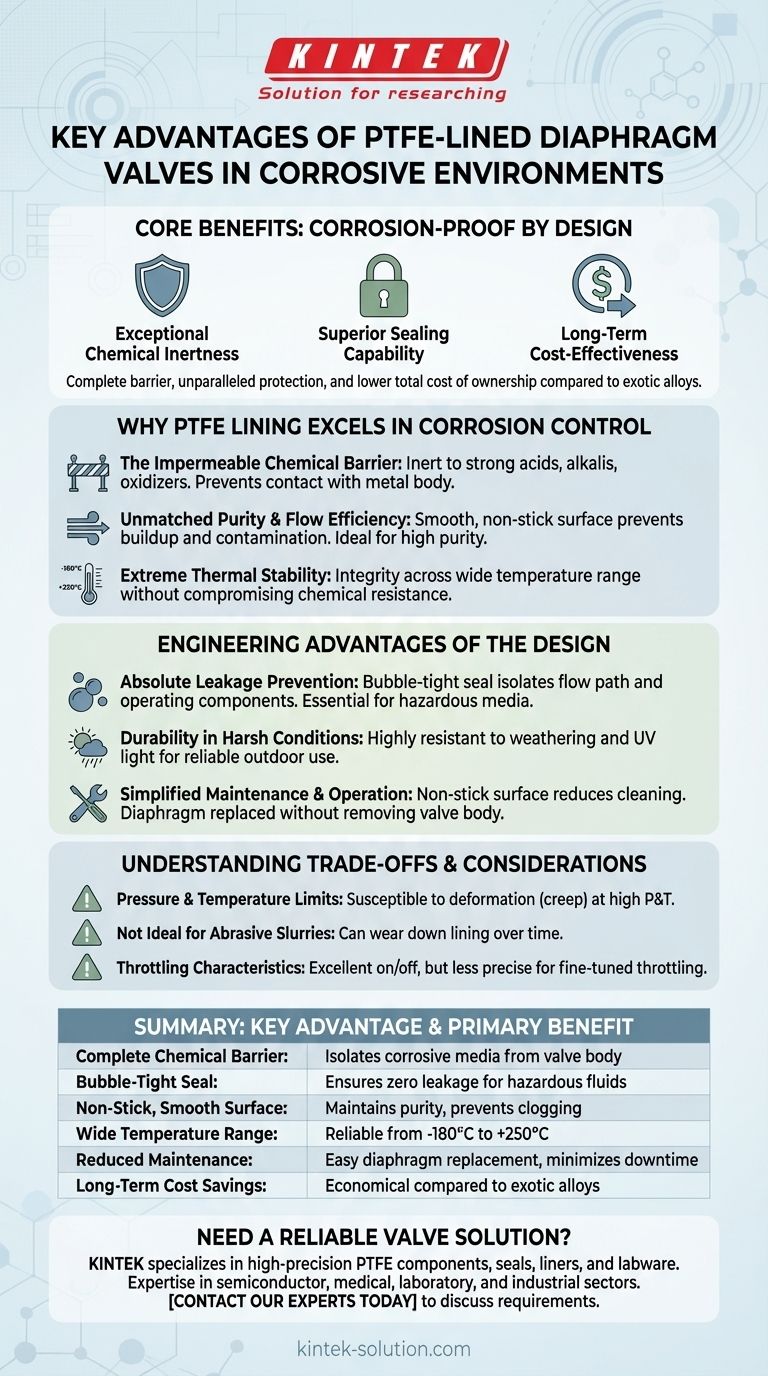

The key advantages of PTFE-lined diaphragm valves in corrosive environments are their exceptional chemical inertness, superior sealing capability, and long-term cost-effectiveness. By creating a complete barrier between the aggressive process media and the valve's structural components, the PTFE lining provides unparalleled protection and reliability where other materials would quickly fail.

These valves are not simply corrosion-resistant; they are corrosion-proof by design. Their core benefit lies in isolating the corrosive fluid from the valve's metal body, which extends operational life, prevents leaks, and significantly lowers the total cost of ownership compared to using expensive exotic alloys.

Why PTFE Lining Excels in Corrosion Control

The performance of these valves stems directly from the unique properties of Polytetrafluoroethylene (PTFE) combined with the mechanical advantages of a diaphragm valve design.

The Impermeable Chemical Barrier

PTFE is one of the most chemically inert polymers known. It is virtually impervious to attack from strong acids, alkalis, oxidizers, and a vast range of industrial chemicals.

The lining acts as an impenetrable barrier, completely preventing the process fluid from ever contacting the valve's metal body. This eliminates corrosion as a failure mechanism.

Unmatched Purity and Flow Efficiency

The surface of PTFE is extremely smooth and non-stick. This characteristic is critical for preventing media buildup, crystallization, or contamination within the valve.

This ensures a smooth, consistent flow path and makes the valves ideal for high-purity applications or for handling viscous and sticky fluids that would clog other valve types.

Extreme Thermal Stability

PTFE maintains its integrity across an exceptionally wide temperature range, typically from -180°C to +250°C (-292°F to +482°F).

This thermal stability allows these valves to be deployed in processes with significant temperature fluctuations without compromising their chemical resistance or structural integrity.

The Engineering Advantages of the Design

Beyond the material science of the lining, the diaphragm valve's mechanics provide additional layers of safety and reliability.

Absolute Leakage Prevention

The diaphragm itself creates a bubble-tight seal that isolates the flow path from the environment and the valve's own operating components (like the stem and actuator).

This leak-proof design is essential for safety and environmental compliance when handling hazardous or toxic media.

Durability in Harsh Conditions

PTFE is highly resistant to degradation from weathering and UV light, a common failure point for many other polymers.

This makes PTFE-lined valves a reliable choice for outdoor installations or equipment exposed to harsh environmental conditions over long periods.

Simplified Maintenance and Operation

The non-stick surface minimizes the need for frequent cleaning. Furthermore, the design of a diaphragm valve often allows the diaphragm to be replaced without removing the entire valve body from the pipeline.

This feature significantly reduces downtime and maintenance costs over the valve's lifespan.

Understanding the Trade-offs and Considerations

While highly effective, no single solution is perfect for every scenario. Being aware of the limitations is key to proper application.

Pressure and Temperature Limits

While the temperature range is broad, PTFE can be susceptible to deformation or "creep" under conditions that combine both high pressure and high temperature. Always verify that your operating conditions are well within the manufacturer's specified limits.

Not Ideal for Abrasive Slurries

The non-stick surface is excellent for viscous fluids, but highly abrasive media can eventually wear down the PTFE lining over many cycles. For heavy slurry applications, a valve with a harder lining material like ceramic may be more appropriate.

Throttling Characteristics

Diaphragm valves provide excellent on/off shut-off and can be used for basic flow control. However, their flow characteristics are generally not as precise or linear as those of a dedicated globe valve, which may be a factor in applications requiring fine-tuned throttling.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal.

- If your primary focus is handling highly aggressive chemicals: The complete chemical inertness of the PTFE lining offers the highest level of safety and equipment longevity.

- If your primary focus is maintaining media purity: The smooth, non-stick surface prevents contamination and product buildup, making it the ideal choice for pharmaceutical, food, or electronics applications.

- If your primary focus is long-term operational cost: The combination of a less expensive base metal with a durable lining offers a lower total cost of ownership than valves made entirely of exotic alloys.

- If your primary focus is safety and leak prevention: The bubble-tight seal inherent in the diaphragm design provides maximum containment for hazardous media.

By understanding these core principles, you can confidently specify PTFE-lined diaphragm valves for critical applications where reliability is non-negotiable.

Summary Table:

| Key Advantage | Primary Benefit |

|---|---|

| Complete Chemical Barrier | Isolates corrosive media from valve body, preventing failure |

| Bubble-Tight Seal | Ensures zero leakage for hazardous or toxic fluids |

| Non-Stick, Smooth Surface | Maintains media purity and prevents clogging |

| Wide Temperature Range | Performs reliably from -180°C to +250°C |

| Reduced Maintenance | Easy diaphragm replacement minimizes downtime |

| Long-Term Cost Savings | More economical than valves made from exotic alloys |

Need a reliable valve solution for your most demanding corrosive applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated seals, liners, and labware. Our expertise ensures your PTFE-lined diaphragm valves deliver maximum chemical resistance, safety, and cost-effectiveness.

Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we prioritize precision production to meet your exact specifications.

Contact our experts today to discuss your project requirements and discover how our PTFE solutions can enhance your system's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers