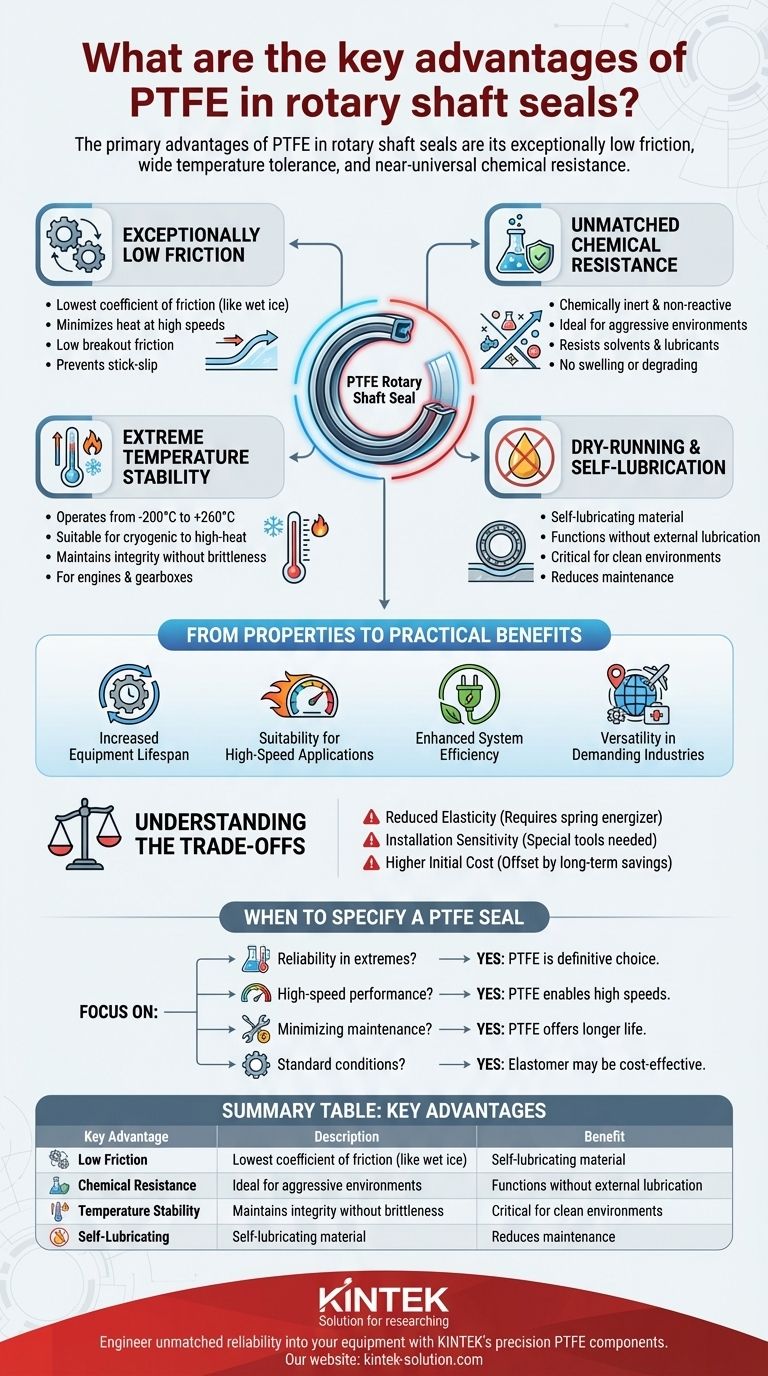

The primary advantages of PTFE in rotary shaft seals are its exceptionally low friction, wide temperature tolerance, and near-universal chemical resistance. These characteristics allow PTFE seals to operate reliably in high-speed, high-temperature, or chemically aggressive environments where traditional elastomer seals would quickly degrade and fail.

The core reason to choose a PTFE seal is for performance under stress. While standard rubber seals are suitable for general-purpose applications, PTFE is a specialized solution engineered to solve failure points related to extreme heat, harsh chemicals, and high rotational speeds.

The Four Pillars of PTFE Seal Performance

The unique molecular structure of Polytetrafluoroethylene (PTFE) gives it a distinct set of properties. These four characteristics are the foundation of its superior performance in demanding sealing applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This minimizes heat generation, even at high rotational speeds.

This property also results in low breakout friction and prevents stick-slip behavior, ensuring smooth, consistent operation from a standstill. The seal glides over the shaft rather than dragging on it.

Unmatched Chemical Resistance

PTFE is chemically inert and non-reactive with nearly all industrial chemicals, solvents, and lubricants.

This makes it an ideal choice for applications in chemical processing, pharmaceuticals, or any system where the seal will be exposed to aggressive fluids that would cause rubber seals to swell, harden, or dissolve.

Extreme Temperature Stability

PTFE seals can function effectively across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to be used in everything from cryogenic applications to high-heat industrial gearboxes and engines without becoming brittle or losing their sealing integrity.

Dry-Running and Self-Lubrication

The material's low-friction nature allows it to be self-lubricating. PTFE seals can often function perfectly well without external lubrication.

This capability is critical for applications where lubrication is undesirable or impossible, such as in food processing or certain clean environments, and it drastically reduces maintenance requirements.

From Properties to Practical Benefits

These core properties translate directly into tangible engineering and financial advantages that improve equipment reliability and reduce long-term costs.

Increased Equipment Lifespan

Because PTFE creates so little friction, it causes significantly less wear on the rotary shaft itself. A worn shaft is expensive and time-consuming to replace.

By preserving the shaft surface and lasting longer itself, a PTFE seal extends the service life of the entire assembly and lowers the total cost of ownership.

Suitability for High-Speed Applications

Traditional elastomer seals generate significant heat from friction at high speeds, which leads to rapid material breakdown and failure.

PTFE's ability to run cool allows it to handle much higher surface speeds, making it essential for high-performance motors, turbines, and compressors.

Enhanced System Efficiency

Less friction means less energy is wasted overcoming the seal's drag. This reduction in operational torque contributes to better overall machine efficiency, a critical factor in energy-conscious designs.

Versatility in Demanding Industries

The combination of chemical inertness, temperature range, and purity (including FDA-approved grades) makes PTFE seals a go-to solution in critical industries. This includes aerospace, food and beverage, and medical equipment.

Understanding the Trade-offs

No material is perfect for every situation. Being an effective advisor means acknowledging the limitations of PTFE compared to traditional elastomers like nitrile or FKM.

Reduced Elasticity

PTFE is a much more rigid plastic compared to flexible rubber. It does not have the same "memory" or elasticity to conform to surface imperfections.

To compensate, most PTFE lip seals are designed with a metal spring energizer that provides the constant force needed to maintain a tight seal against the shaft.

Installation Sensitivity

Due to its rigidity, a PTFE seal lip can be damaged during installation if not handled with care. Unlike a rubber seal that can be easily stretched over a shaft, PTFE often requires special tools or techniques to prevent nicks or permanent deformation.

Higher Initial Cost

PTFE seals are generally more expensive to manufacture than standard elastomer seals. However, this higher upfront cost is frequently justified by the dramatic reduction in maintenance, downtime, and collateral equipment damage.

When to Specify a PTFE Seal

Choosing the right seal requires matching the material's strengths to the application's demands.

- If your primary focus is reliability in extreme temperatures or with aggressive chemicals: PTFE is the definitive choice due to its unmatched stability and inertness where rubber would fail.

- If your primary focus is high-speed performance and energy efficiency: The low-friction properties of PTFE will reduce heat and torque, enabling speeds that would destroy elastomer seals.

- If your primary focus is minimizing maintenance and total cost of ownership: PTFE's durability and self-lubricating capability lead to a longer life for both the seal and the shaft, justifying the initial investment.

- If your application operates under standard conditions with no extremes: A traditional elastomer seal may be a more forgiving and cost-effective solution.

Ultimately, specifying a PTFE seal is a strategic decision to engineer reliability into equipment that operates at the outer limits of performance.

Summary Table:

| Key Advantage | Description | Benefit |

|---|---|---|

| Low Friction | One of the lowest coefficients of friction of any solid material. | Reduces heat, energy consumption, and wear on the shaft. |

| Chemical Resistance | Inert and non-reactive with nearly all industrial chemicals. | Ideal for aggressive environments where rubber seals fail. |

| Temperature Stability | Operates from -200°C to +260°C (-328°F to +500°F). | Suitable for cryogenic to high-heat applications without losing integrity. |

| Self-Lubricating | Can run dry without external lubrication. | Reduces maintenance and is perfect for clean or food-processing environments. |

Engineer unmatched reliability into your equipment with KINTEK's precision PTFE components.

Our PTFE seals, liners, and labware are manufactured to solve failure points in the most demanding environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders to ensure your equipment operates flawlessly under stress.

Contact KINTEK today to discuss your specific application and receive a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications