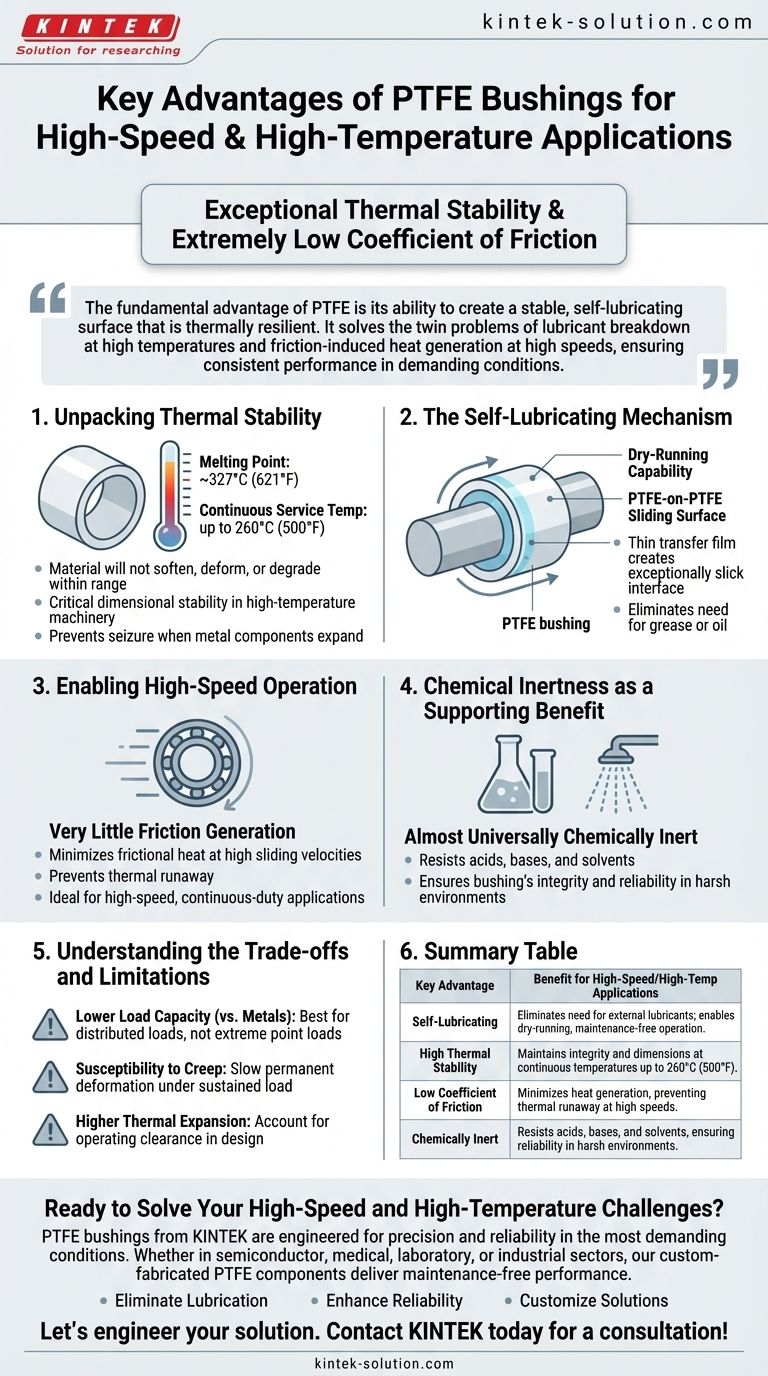

For high-speed and high-temperature environments, the key advantages of PTFE bushings are their exceptional thermal stability and an extremely low coefficient of friction. These two core properties allow the bushings to operate without any external lubrication, creating a maintenance-free system that resists the heat and friction that cause traditional lubricated metal bearings to fail.

The fundamental advantage of PTFE is its ability to create a stable, self-lubricating surface that is thermally resilient. It solves the twin problems of lubricant breakdown at high temperatures and friction-induced heat generation at high speeds, ensuring consistent performance in demanding conditions.

The Science of PTFE in Demanding Conditions

To understand why PTFE (Polytetrafluoroethylene) is specified for these challenging applications, we must look at how its molecular properties translate into mechanical advantages. It isn't just one feature, but the combination of several that allows it to succeed.

Unpacking Thermal Stability

PTFE has an extremely high melting point for a polymer, around 327°C (621°F), and a continuous service temperature of up to 260°C (500°F).

This means that within its operating range, the bushing material will not soften, deform, or degrade. This dimensional stability is critical in high-temperature machinery, preventing the seizure or failure that can occur when metal components expand and clearances tighten.

The Self-Lubricating Mechanism

PTFE bushings are often described as "self-lubricating" or capable of dry-running. This is their most critical feature for high-speed applications.

During initial operation, an imperceptibly thin layer of the PTFE material transfers from the bushing to the mating shaft. This creates a PTFE-on-PTFE sliding surface.

Because PTFE has one of the lowest coefficients of friction of any solid material, this transfer film creates an exceptionally slick interface. The bushing effectively lubricates itself, eliminating the need for grease or oil.

Enabling High-Speed Operation

High rotational speeds generate significant frictional heat. In a lubricated metal bearing, this heat can cause the lubricant to break down, leading to rapid wear and failure.

Because PTFE's self-lubricating mechanism generates very little friction, it also generates very little heat. This allows for high sliding velocities without the risk of thermal runaway, making it ideal for high-speed, continuous-duty applications.

Chemical Inertness as a Supporting Benefit

In many industrial settings, high temperatures are accompanied by corrosive chemicals or wash-down fluids.

PTFE is almost universally chemically inert. It will not react with or be degraded by acids, bases, or solvents. This ensures the bushing's integrity and performance are maintained, adding a layer of reliability in harsh environments.

Understanding the Trade-offs and Limitations

While PTFE offers remarkable advantages, it is essential to understand its limitations to specify it correctly. It is not a universal replacement for all bearing types.

Lower Load Capacity Than Metals

While PTFE bushings can handle high loads relative to other polymers, they do not possess the compressive strength of hardened steel or bronze bearings.

They are best suited for applications with distributed loads. They may not be appropriate for scenarios with extreme point loads or severe impact forces.

Susceptibility to Creep

Like most polymers, PTFE can be subject to creep, also known as cold flow. This is a slow, permanent deformation that occurs under a sustained load over time.

This must be a consideration in the design phase, particularly for applications involving high static loads at elevated temperatures.

Higher Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more significantly with temperature changes.

Designers must account for this to ensure proper operating clearance is maintained across the entire temperature range, preventing binding when hot or excessive play when cold.

Making the Right Choice for Your Application

Selecting the right bushing requires matching the material's strengths to your primary operational goal.

- If your primary focus is maximizing speed and eliminating lubrication: PTFE is an ideal choice, as its low-friction transfer film minimizes heat generation and allows for maintenance-free, high-velocity operation.

- If your primary focus is reliability in a high-heat environment: PTFE's thermal stability ensures it maintains its dimensions and strength, preventing failures where lubricants would burn off and metals could seize.

- If your primary focus is performance in a clean or corrosive environment: PTFE's chemical inertness and dry-running capability make it perfect for food processing (FDA/USDA compliant), chemical, and medical applications where contamination from lubricants is unacceptable.

Ultimately, choosing PTFE bushings is a strategic decision for creating reliable, low-maintenance systems that thrive under thermal and kinetic stress.

Summary Table:

| Key Advantage | Benefit for High-Speed/High-Temp Applications |

|---|---|

| Self-Lubricating | Eliminates need for external lubricants; enables dry-running, maintenance-free operation. |

| High Thermal Stability | Maintains integrity and dimensions at continuous temperatures up to 260°C (500°F). |

| Low Coefficient of Friction | Minimizes heat generation, preventing thermal runaway at high speeds. |

| Chemically Inert | Resists acids, bases, and solvents, ensuring reliability in harsh environments. |

Ready to Solve Your High-Speed and High-Temperature Challenges?

PTFE bushings from KINTEK are engineered for precision and reliability in the most demanding conditions. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE components—from prototypes to high-volume orders—are designed to deliver maintenance-free performance and extended service life.

We help you:

- Eliminate Lubrication: Achieve clean, contamination-free operation.

- Enhance Reliability: Prevent downtime with components built for thermal and kinetic stress.

- Customize Solutions: Get parts tailored to your exact specifications and application requirements.

Let's engineer your solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions