At its core, Polytetrafluoroethylene (PTFE) excels as a solid lubricant due to its remarkably low coefficient of friction, exceptional chemical inertness, and wide operational temperature range. Unlike traditional oils and greases, it provides a clean, dry, non-stick lubricating film that resists contamination and protects surfaces in extreme conditions.

The true advantage of PTFE isn't just one of its properties, but the unique combination that makes it a "problem-solver" lubricant. It functions where conventional wet lubricants would fail due to chemical attack, temperature breakdown, or contamination from dust and dirt.

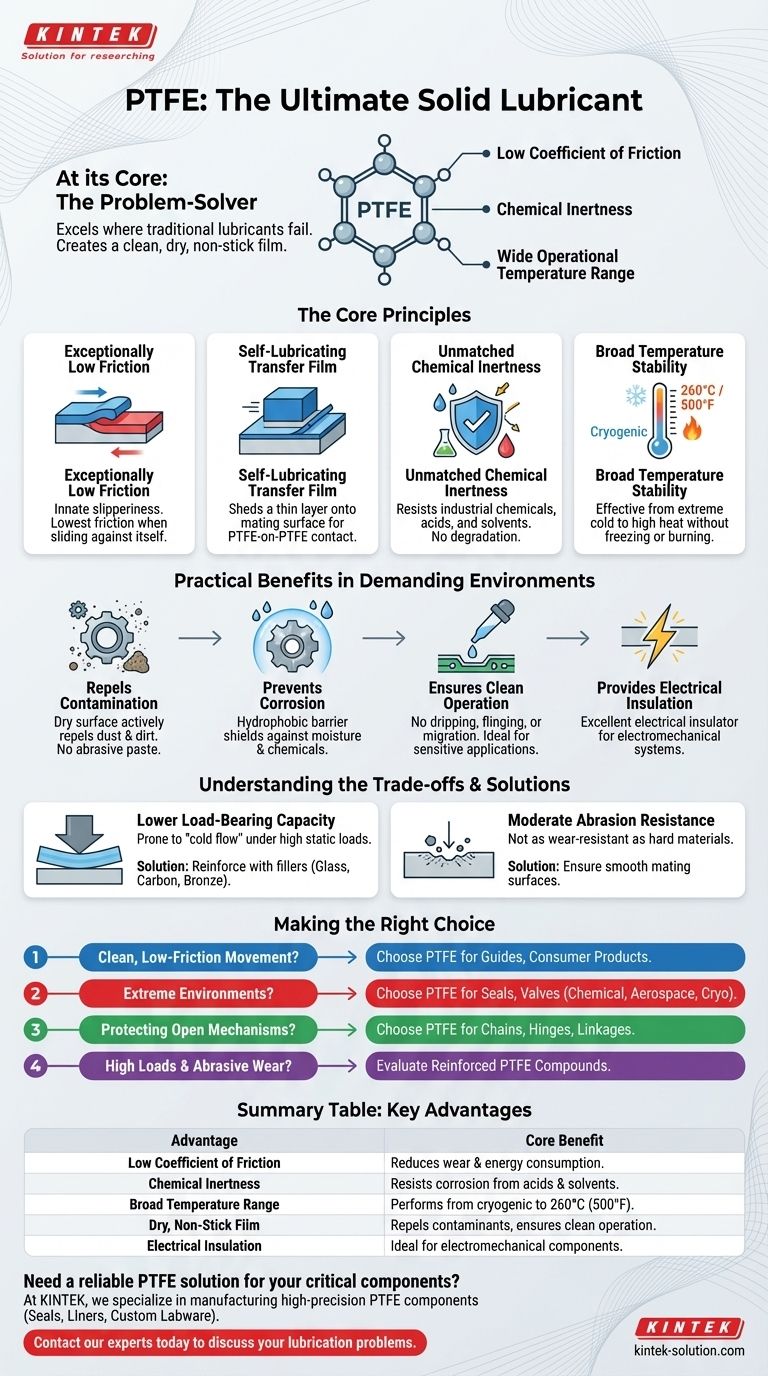

The Core Principles of PTFE Lubrication

To understand why PTFE is so effective, we must look beyond its surface-level benefits to the fundamental properties that drive its performance.

Exceptionally Low Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This innate "slipperiness" is its most defining characteristic.

The friction is lowest when PTFE slides against itself. Its mechanism relies on creating this ideal interface.

The Self-Lubricating Transfer Film

During initial operation, PTFE sheds a very thin, invisible layer of itself onto the mating surface.

This transfer film creates a PTFE-on-PTFE sliding contact. This ensures the friction remains incredibly low and that the lubrication is continuous as long as the film is present.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, acids, and solvents.

This property means it can be used to lubricate components in highly corrosive environments without degrading or causing a reaction, which is a common point of failure for oil-based products.

Broad Temperature Stability

PTFE remains an effective lubricant over an exceptionally wide temperature range, typically from cryogenic temperatures up to approximately 260°C (500°F).

Traditional lubricants would freeze, thicken, or burn off under these conditions, while PTFE maintains its integrity and lubricity.

Practical Benefits in Demanding Environments

These core principles translate directly into tangible advantages for mechanical systems, especially those operating outside of ideal conditions.

Repels Contamination

Because PTFE creates a dry, non-stick surface, it actively repels dust, dirt, and other airborne particles.

This is a critical advantage over traditional "wet" lubricants like grease, which act as a magnet for contaminants that can form an abrasive paste and accelerate wear.

Prevents Corrosion

PTFE's chemical inertness and hydrophobic (water-repelling) nature create a protective barrier on the component's surface.

This film shields the underlying metal from moisture and chemicals, significantly reducing the risk of corrosion.

Ensures Clean Operation

As a solid film lubricant, PTFE does not drip, fling, or migrate.

This makes it the ideal choice for applications where cleanliness is paramount, such as in food processing, medical devices, or sensitive electronics.

Provides Electrical Insulation

PTFE is also an excellent electrical insulator. This is an important secondary benefit in electromechanical applications where lubrication is needed without creating a path for electrical current.

Understanding the Trade-offs

No material is a perfect solution for every problem. To use PTFE effectively, it is critical to understand its limitations.

Lower Load-Bearing Capacity

Pure PTFE is a relatively soft material. Under extremely high static loads, it can be prone to "cold flow," a type of deformation.

For high-pressure applications, PTFE is often reinforced with fillers like glass, carbon, or bronze to improve its compressive strength and wear resistance.

Moderate Abrasion Resistance

While excellent for sliding friction, PTFE is not as resistant to abrasive wear as harder materials. In environments with significant abrasive media, the lubricating film may wear away more quickly.

The longevity of the coating is directly tied to the operating conditions and the smoothness of the mating surfaces.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on the specific demands of your application.

- If your primary focus is clean, low-friction movement: PTFE is an outstanding choice for guides, slideways, and consumer products where messy oils are not acceptable.

- If your primary focus is performance in extreme environments: Its stability makes it perfect for seals, valves, and components in chemical processing, aerospace, or cryogenic applications.

- If your primary focus is protecting open mechanisms: The dry, contaminant-repelling nature of PTFE excels in lubricating chains, hinges, and linkages exposed to dust and dirt.

- If your primary focus is managing high loads and abrasive wear: You should evaluate a filled or reinforced PTFE compound rather than a pure PTFE coating.

Ultimately, leveraging PTFE effectively comes from understanding its unique ability to provide clean, stable lubrication where other options cannot.

Summary Table:

| Key Advantage | Core Benefit |

|---|---|

| Low Coefficient of Friction | Reduces wear and energy consumption. |

| Chemical Inertness | Resists corrosion from acids and solvents. |

| Broad Temperature Range | Performs from cryogenic to 260°C (500°F). |

| Dry, Non-Stick Film | Repels contaminants and ensures clean operation. |

| Electrical Insulation | Ideal for electromechanical components. |

Need a reliable PTFE solution for your critical components?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our custom fabrication ensures your equipment benefits from PTFE's superior lubricating properties.

Contact our experts today to discuss how our PTFE components can solve your most challenging lubrication problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications