In the world of industrial sealing, expanded Polytetrafluoroethylene (ePTFE) stands out for its unique combination of elite performance characteristics. Its primary advantages are exceptional chemical resistance across nearly the entire pH scale, a very wide service temperature range, and a highly compressible structure that allows it to seal imperfect surfaces under low bolt load. This makes it a premier choice for demanding applications where purity and reliability are non-negotiable.

The core value of ePTFE gasket material is not just one superior feature, but its unique synergy of chemical inertness, thermal stability, and mechanical conformability. It solves complex sealing challenges, particularly in fragile or irregular flanges, where other materials would fail.

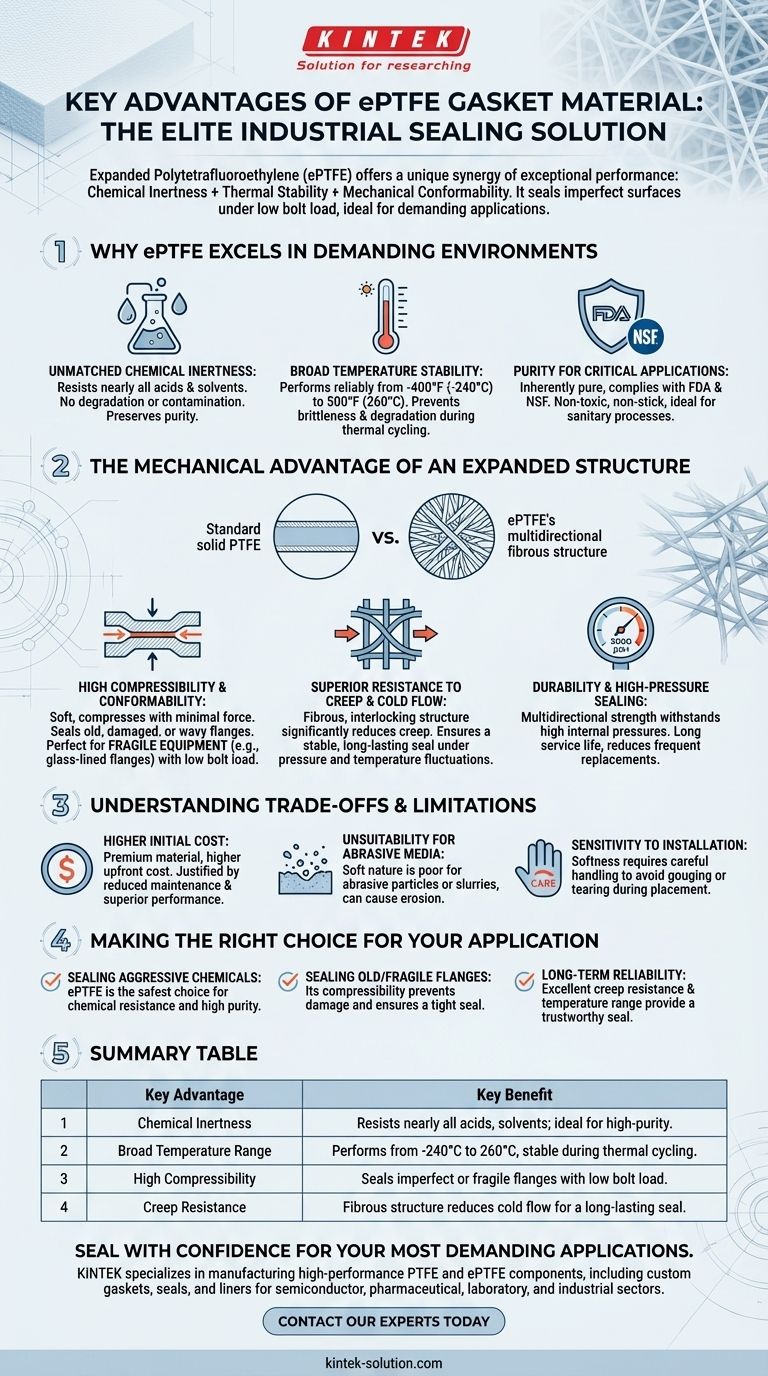

Why ePTFE Excels in Demanding Environments

The properties of ePTFE make it a problem-solver for the most challenging industrial sealing applications, from chemical processing to pharmaceuticals.

Unmatched Chemical Inertness

ePTFE is resistant to nearly all chemicals, including highly aggressive acids and solvents. Its only known vulnerabilities are molten alkali metals and elemental fluorine at high temperatures.

This extreme inertness ensures the gasket will not degrade, swell, or contaminate the process media, preserving both the integrity of the seal and the purity of the product.

Broad Temperature Stability

This material performs reliably across an exceptionally wide temperature range, typically from cryogenic conditions around -400°F (-240°C) up to 500°F (260°C).

This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, ensuring a consistent and dependable seal during thermal cycling.

Purity for Critical Applications

ePTFE is inherently pure and complies with stringent FDA and NSF regulations for food, drinking water, and pharmaceutical contact.

Its non-toxic and non-stick surface is easy to clean and does not impart taste, color, or contaminants, making it ideal for sanitary processes.

The Mechanical Advantage of an Expanded Structure

The manufacturing process that "expands" PTFE creates a multidirectional fibrous structure. This structure is the source of its most significant mechanical advantages over standard, solid PTFE.

High Compressibility and Conformability

ePTFE is soft and highly compressible, allowing it to conform to surface irregularities with minimal force. This is a critical advantage when sealing old, damaged, or wavy flanges.

It excels in applications involving fragile equipment, such as glass-lined flanges, where high bolt torque would risk cracking the lining. ePTFE creates a tight seal with very low bolt load.

Superior Resistance to Creep and Cold Flow

Creep (or cold flow) is the tendency of a gasket material to deform or "flow" away from the compressive load over time. This leads to a loss of bolt torque and potential leaks.

The fibrous, interlocking structure of ePTFE significantly reduces creep, a known weakness of standard PTFE. This ensures a more stable, long-lasting seal that maintains its integrity under pressure and temperature fluctuations.

Durability and High-Pressure Sealing

Despite its softness, the multidirectional strength of ePTFE allows it to withstand high internal pressures, with some variants rated for over 3000 psi.

This combination of softness for sealing and strength for pressure containment results in a long service life and reduces the need for frequent gasket replacement.

Understanding the Trade-offs and Limitations

No material is perfect for every application. To make an informed decision, it's crucial to understand ePTFE's limitations.

Higher Initial Cost

ePTFE is a premium material, and its upfront cost is generally higher than that of elastomer gaskets or standard PTFE sheets.

This cost, however, is often justified by reduced maintenance, less downtime, and superior performance that prevents costly product loss or safety incidents.

Unsuitability for Abrasive Media

The soft nature of ePTFE makes it a poor choice for services containing abrasive particles or slurries, which can quickly erode the gasket material and cause seal failure.

Sensitivity to Installation

While ePTFE is easy to cut and form, its softness means it can be damaged by careless handling or improper installation techniques. Care must be taken to avoid gouging or tearing the material during placement.

Making the Right Choice for Your Application

Selecting ePTFE is a strategic decision based on the specific demands of the service environment.

- If your primary focus is sealing aggressive chemicals or high-purity media: ePTFE's near-total chemical inertness and FDA compliance make it the safest and most reliable choice.

- If your primary focus is sealing old, damaged, or fragile flanges: Its high compressibility and low-load sealing capability will prevent equipment damage while ensuring a tight seal.

- If your primary focus is long-term reliability in fluctuating temperatures: Its excellent resistance to creep and its wide service temperature range provide a stable, leak-free seal you can trust.

Ultimately, choosing ePTFE is an investment in operational certainty for your most critical sealing applications.

Summary Table:

| Key Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists nearly all acids, solvents; ideal for high-purity processes. |

| Broad Temperature Range | Performs from -240°C to 260°C, stable during thermal cycling. |

| High Compressibility | Seals imperfect or fragile flanges (e.g., glass-lined) with low bolt load. |

| Creep Resistance | Fibrous structure reduces cold flow, ensuring a long-lasting, stable seal. |

Seal with Confidence for Your Most Demanding Applications

Struggling with sealing aggressive chemicals, maintaining product purity, or sealing fragile flanges without damage? The unique properties of ePTFE material provide the reliable, long-term solution you need.

KINTEK specializes in manufacturing high-performance PTFE and ePTFE components, including custom gaskets, seals, and liners. We serve the semiconductor, pharmaceutical, laboratory, and industrial sectors where precision and reliability are critical.

We partner with you from prototype to high-volume production, ensuring you get a component that perfectly matches your application's requirements.

Let's solve your toughest sealing challenges together. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications