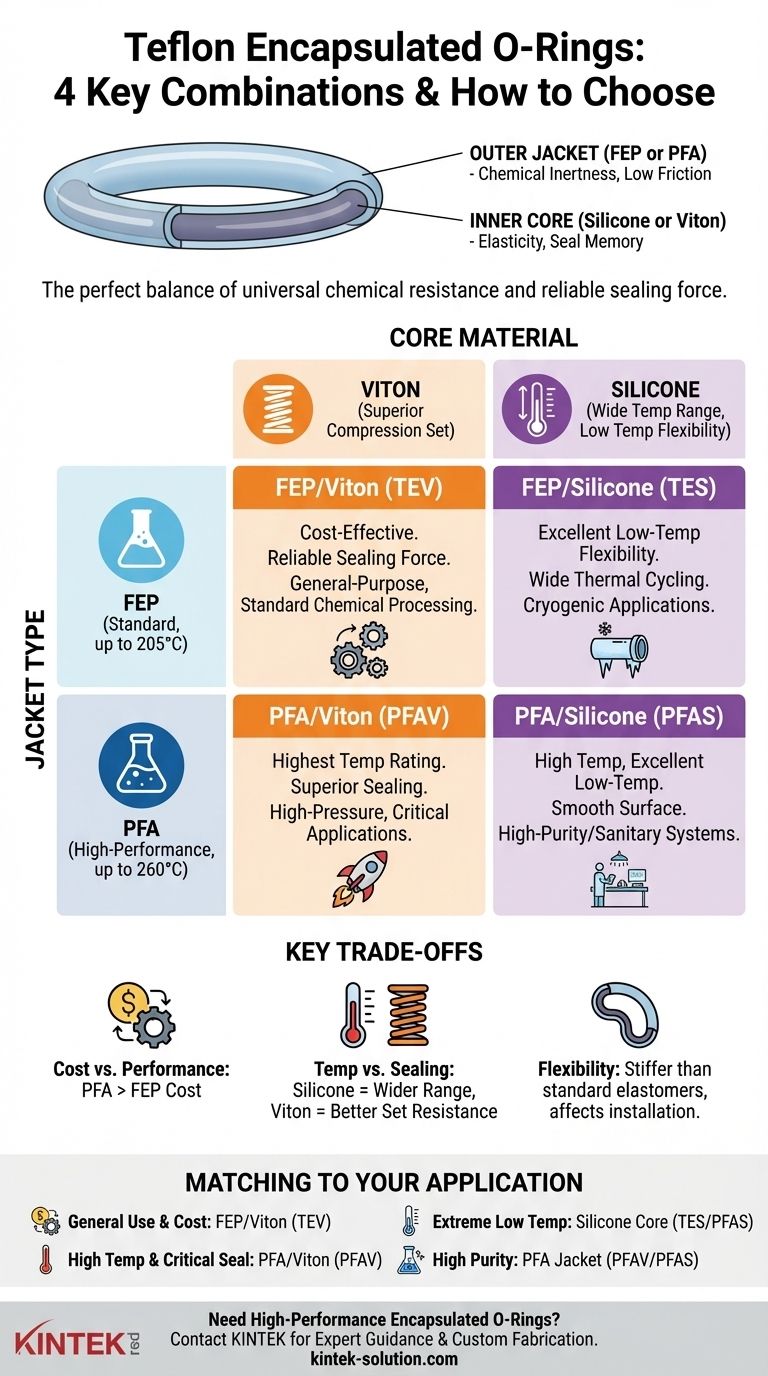

The four standard combinations of jacket type and elastomer core used in Teflon encapsulated O-rings are FEP/Viton, FEP/Silicone, PFA/Viton, and PFA/Silicone. Each pairing is designed to leverage the unique properties of its components, offering a specific balance of chemical resistance, temperature range, and sealing performance.

The outer Teflon jacket provides universal chemical resistance, while the inner elastomer core provides the physical resilience needed for a reliable seal. Your selection is a critical engineering choice that balances the superior temperature and mechanical properties of PFA against FEP, and the excellent compression resistance of Viton against the wider temperature range of Silicone.

The Anatomy of an Encapsulated O-Ring

To understand the four combinations, you must first understand the role of each component. These O-rings feature a two-part construction that creates a seal with properties that neither material could achieve alone.

The Function of the Outer Jacket

The seamless outer jacket is made from either Teflon FEP or PFA. This layer is what contacts the process media, providing the extreme chemical inertness and low-friction surface that Teflon is known for.

The Role of the Inner Core

The inner core is a standard elastomer, typically Silicone or Viton® (FKM). This core provides the "memory" and elasticity, allowing the O-ring to compress and conform to the sealing surface and rebound when pressure is removed.

Deconstructing the Jacket Materials: FEP vs. PFA

The choice of jacket material is the first major decision point. It primarily dictates the O-ring's temperature limits and mechanical durability.

Teflon FEP (Fluorinated Ethylene Propylene)

FEP is the standard and most common jacket material. It offers excellent chemical resistance and a broad service temperature range, typically up to 205°C (400°F). It provides a cost-effective solution for a vast majority of applications.

Teflon PFA (Perfluoroalkoxy)

PFA is the high-performance option. It has all the benefits of FEP but with a higher temperature rating, up to 260°C (500°F). PFA also offers better creep resistance, a lower coefficient of friction, and a smoother surface finish, making it ideal for more demanding or sanitary applications.

Deconstructing the Core Materials: Silicone vs. Viton (FKM)

The choice of core material dictates the O-ring's flexibility and its ability to maintain a consistent sealing force over time, a property known as compression set resistance.

Silicone Core

Silicone's primary advantage is its excellent temperature range, particularly for low-temperature flexibility, remaining effective down to -60°C (-75°F). This makes it the default choice for cryogenic or wide-ranging thermal applications.

Viton® (FKM) Core

Viton is the industry standard for superior compression set resistance. It maintains its shape and sealing force far better than silicone under sustained pressure and high temperatures, leading to a more reliable, long-term seal in stable, high-pressure environments.

Understanding the Trade-offs

There is no single "best" encapsulated O-ring; each combination represents a deliberate compromise.

Cost vs. Performance

The most significant trade-off is cost. PFA jacketed O-rings are more expensive than their FEP counterparts. This cost is only justified when the application demands the higher temperature limits or superior mechanical properties that PFA provides.

Temperature Range vs. Sealing Force

This is the core dilemma between Silicone and Viton. Silicone offers a wider operating window, especially for cold service. However, Viton provides a more robust and lasting seal due to its resistance to taking a permanent set under pressure.

Flexibility and Installation

A universal characteristic of all encapsulated O-rings is their relative stiffness compared to a standard elastomer O-ring. The Teflon jacket reduces flexibility, which can make installation more challenging, particularly with smaller diameters.

Matching the O-Ring to Your Application

Your final selection should be driven by the primary demands of your system.

- If your primary focus is general-purpose use and cost-effectiveness: Choose an FEP/Viton (TEV) combination for its excellent balance of chemical resistance and reliable sealing force.

- If your primary focus is high-temperature service or critical sealing: Choose a PFA/Viton (PFAV) combination to leverage the best jacket material with the core that has the best compression set resistance.

- If your primary focus is extreme low-temperature flexibility: Choose a Silicone core with either an FEP (TES) or PFA (PFAS) jacket, depending on your upper temperature requirements.

- If your primary focus is high purity or preventing contamination: Choose a PFA jacket for its smoother surface finish, which reduces particle shedding and buildup.

By systematically evaluating your requirements for temperature, pressure, and chemical compatibility, you can confidently select the combination that provides the most reliable and effective seal.

Summary Table:

| Combination | Jacket Material | Core Material | Key Characteristics | Typical Use Case |

|---|---|---|---|---|

| FEP/Viton (TEV) | FEP | Viton (FKM) | Cost-effective, good chemical resistance, reliable sealing force | General-purpose applications, standard chemical processing |

| FEP/Silicone (TES) | FEP | Silicone | Excellent low-temperature flexibility, wide temperature range | Cryogenic applications, wide thermal cycling |

| PFA/Viton (PFAV) | PFA | Viton (FKM) | Highest temperature rating (260°C), superior compression set resistance | High-temperature, high-pressure, critical sealing applications |

| PFA/Silicone (PFAS) | PFA | Silicone | High-temperature rating, excellent low-temperature flexibility, smooth surface | High-purity/sanitary systems requiring a wide temperature range |

Need High-Performance Teflon Encapsulated O-Rings?

Selecting the right FEP or PFA encapsulated O-ring is critical for the reliability of your semiconductor, medical, laboratory, or industrial equipment. KINTEK specializes in the precision manufacturing of PTFE components, including custom encapsulated O-rings.

We provide:

- Expert Guidance: Our team helps you select the ideal jacket and core combination for your specific temperature, pressure, and chemical compatibility requirements.

- Custom Fabrication: From prototypes to high-volume orders, we manufacture O-rings to your exact specifications.

- Guaranteed Quality: Benefit from the superior chemical resistance and sealing performance of our precision-engineered components.

Ensure a leak-free, reliable seal in your most demanding applications. Contact KINTEK today for a quote or to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions