Teflon, technically known as Polytetrafluoroethylene (PTFE), is exceptionally fire-resistant. By its very nature, it is classified as a non-flammable material. Its unique chemical structure is inherently stable and does not support combustion, making it a reliable choice for applications where fire safety is a critical requirement.

Teflon's exceptional fire safety is a direct result of the powerful carbon-fluorine bonds at its molecular core. This structure is not only non-flammable but also provides high thermal stability, making the material a safe and predictable component within its specified temperature limits.

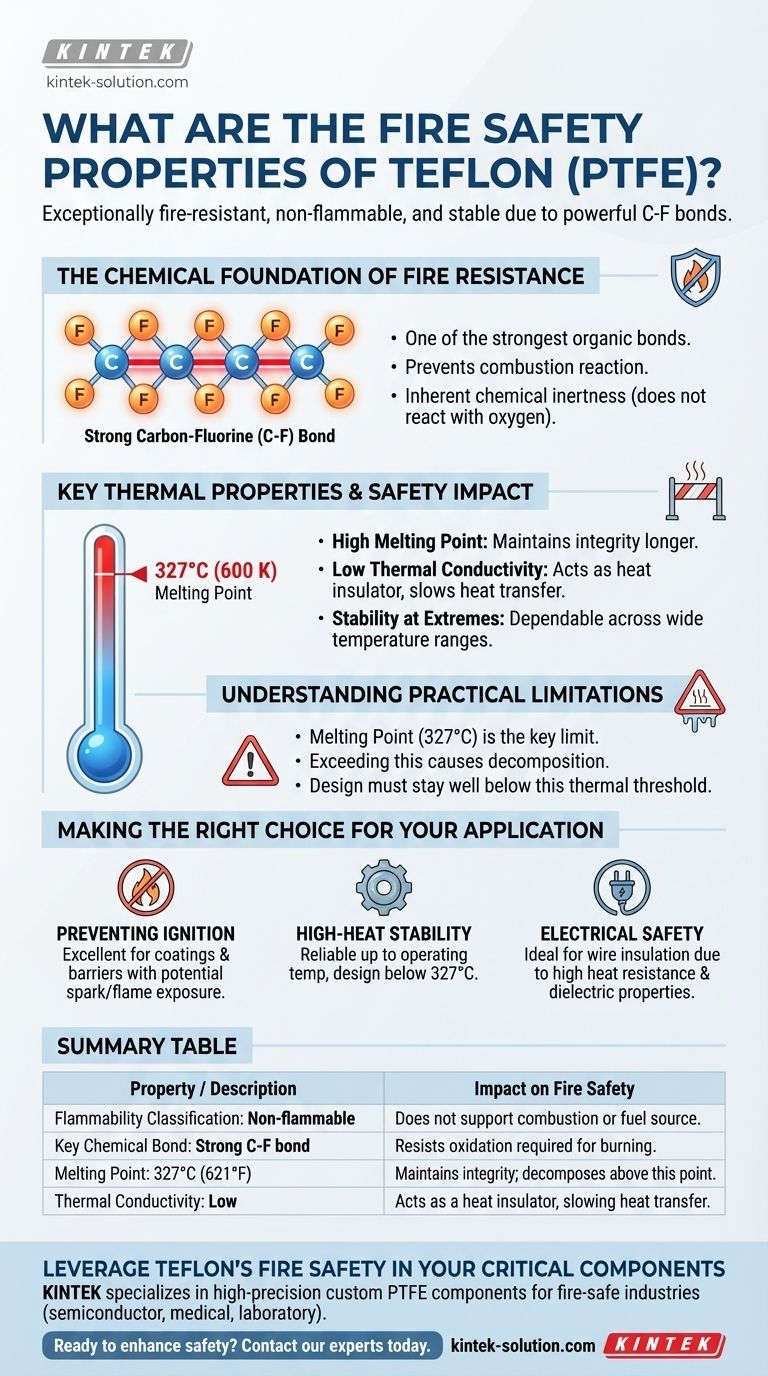

The Chemical Foundation of Teflon's Fire Resistance

To truly understand Teflon's safety profile, we must look at its molecular structure. Its properties are not additives; they are fundamental to the material itself.

The Strength of the Carbon-Fluorine Bond

The Teflon polymer is a long chain of carbon atoms, each completely shielded by fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest known single bonds in organic chemistry.

This bond requires a tremendous amount of energy to break. Since combustion is a rapid oxidation process that breaks molecular bonds, the strength of the C-F bond effectively prevents the chemical reaction of burning from starting.

Inherent Chemical Inertness

Teflon is famously unreactive. It is resistant to acids, bases, and nearly all solvents. This inertness extends to oxidation, which is the primary process in combustion. The material simply does not react with oxygen, even at elevated temperatures, to sustain a flame.

Key Thermal Properties and Their Impact on Safety

Teflon's behavior when exposed to heat is a critical component of its fire safety profile. It remains stable and predictable across a wide range of temperatures.

High Melting Point

Teflon has a very high melting point for a polymer, around 327°C (600 K). This means it maintains its solid form and structural integrity long after many other materials would have melted or ignited.

Low Thermal Conductivity

Teflon is a poor conductor of heat, meaning it acts as an insulator. This property can help slow the transfer of heat, which can be beneficial in components designed to act as a fire or heat barrier.

Stability at Temperature Extremes

In addition to its high heat resistance, Teflon remains flexible and functional at very low temperatures. This overall thermal robustness makes it a dependable material in systems that experience wide temperature fluctuations.

Understanding the Practical Limitations

While Teflon is non-flammable, no material has infinite tolerance. A technical advisor's role is to ensure you understand a material's operational boundaries for safe and effective design.

Stability Within Operating Limits

Teflon’s non-flammability and lack of fume emission are properties observed when the material is exposed to flames or heat while in its solid state. It does not burn or contribute fuel to a fire.

The Importance of the Melting Point

The key limitation is the material's melting point of 327°C. While it will not ignite, exceeding this temperature will cause the material to decompose. Any engineering application must be designed to keep Teflon operating well below this thermal threshold.

Context Is Crucial

For applications like non-stick coatings or flame-resistant fabrics, Teflon's performance is exceptional and well-understood. For industrial systems where extreme temperatures are possible, a full system safety analysis must account for the material's behavior if its decomposition temperature is ever reached.

Making the Right Choice for Your Application

Leveraging Teflon's properties effectively depends entirely on your primary goal.

- If your primary focus is preventing ignition: Teflon's non-flammable nature makes it an excellent choice for coatings, barriers, or components in environments with potential spark or flame exposure.

- If your primary focus is material stability in high-heat environments: Teflon is reliable up to its significant operating temperature, but you must design your system to remain well below its 327°C (600 K) melting point.

- If your primary focus is electrical safety: Its combination of high heat resistance and excellent dielectric properties makes it ideal for wire insulation, preventing short circuits that could lead to electrical fires.

By understanding both its inherent fire resistance and its thermal limits, you can confidently leverage Teflon's properties to build safer, more reliable systems.

Summary Table:

| Property | Value / Description | Impact on Fire Safety |

|---|---|---|

| Flammability Classification | Non-flammable | Does not support combustion or act as a fuel source. |

| Key Chemical Bond | Strong Carbon-Fluorine (C-F) bond | Resists the oxidation process required for burning. |

| Melting Point | 327°C (621°F) | Maintains integrity at high temperatures; decomposes above this point. |

| Thermal Conductivity | Low | Acts as a heat insulator, slowing heat transfer. |

Leverage Teflon's Fire Safety in Your Critical Components

Understanding the precise thermal limits of PTFE is key to designing safe, reliable systems. KINTEK specializes in manufacturing high-precision, custom PTFE components—including seals, liners, and labware—for industries where fire safety is paramount, such as semiconductor, medical, and laboratory equipment.

We ensure your custom parts are fabricated to the highest standards, from prototype to high-volume production, helping you harness Teflon's non-flammable properties effectively.

Ready to enhance your product's safety with precision PTFE components? Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers