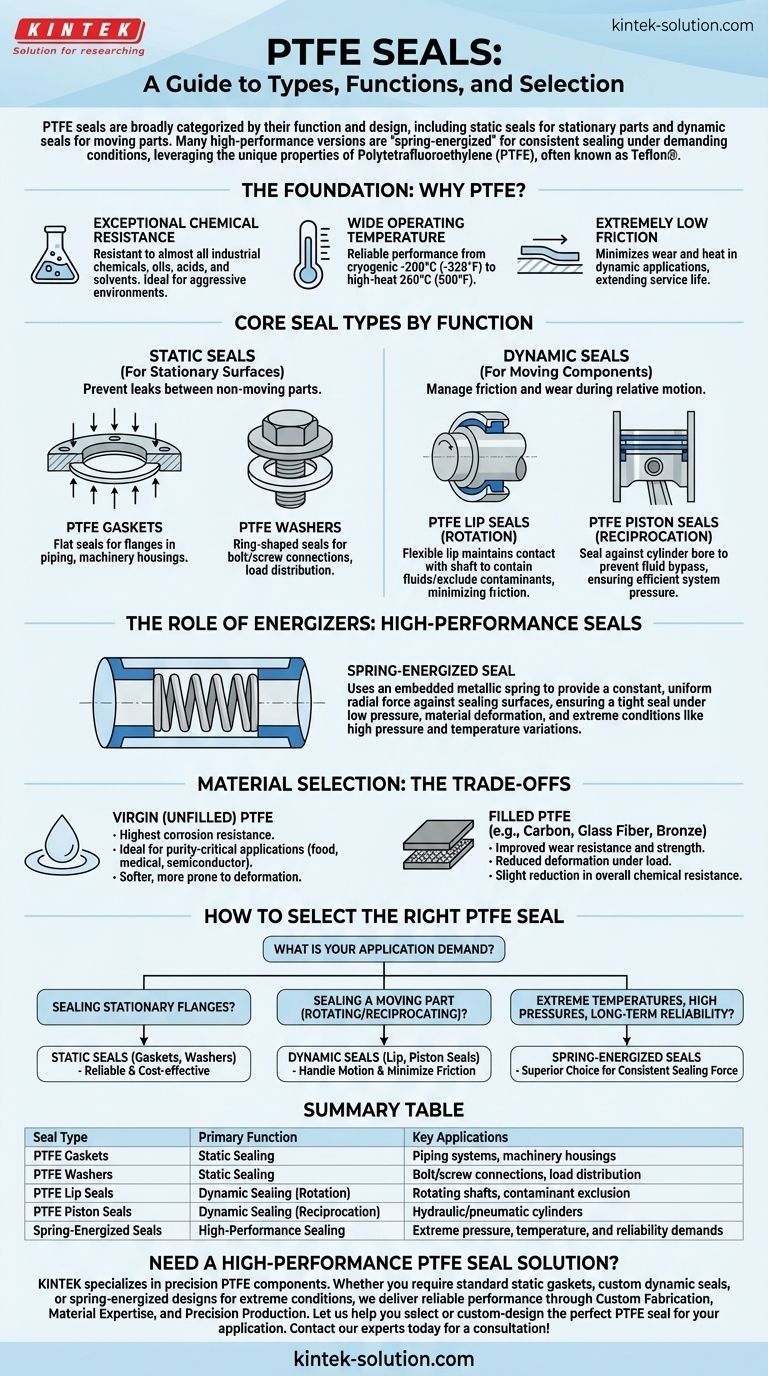

PTFE seals are broadly categorized by their function and design, including simple static seals like gaskets and advanced dynamic seals like lip, piston, and rotary seals. Many high-performance versions are "spring-energized" to ensure a consistent seal under demanding operational conditions, leveraging the unique properties of Polytetrafluoroethylene (PTFE), often known by the brand name Teflon®.

The critical distinction when selecting a seal is between static applications (sealing stationary parts) and dynamic applications (sealing moving parts). Your final choice is then refined by the system's pressure, temperature, and motion, which dictates the specific design and PTFE material required.

The Foundation: Why PTFE is a Premier Sealing Material

Before categorizing the seals themselves, it's essential to understand why PTFE is the material of choice for challenging environments. Its properties directly influence seal performance and application range.

Exceptional Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals, oils, acids, and solvents. This makes it invaluable in aggressive chemical processing and manufacturing environments.

Wide Operating Temperature

PTFE seals provide reliable performance across an exceptionally broad temperature range, from cryogenic conditions at -200°C (-328°F) up to high-heat applications at 260°C (500°F).

Extremely Low Friction

The material has one of the lowest coefficients of friction of any solid. This "non-stick" property minimizes wear and heat generation in dynamic applications, extending the service life of both the seal and the equipment.

Core Seal Types by Function

The most effective way to understand PTFE seals is to group them by their primary function: static or dynamic.

Static Seals: For Stationary Surfaces

Static seals are designed to prevent leaks between two mating surfaces that do not move relative to one another. Their job is to fill imperfections and create a barrier.

PTFE gaskets are flat seals used to create a barrier between two stationary flanges, such as in piping systems or machinery housings.

PTFE washers are ring-shaped seals typically used under the head of a bolt or screw to distribute the load and ensure a tight, leak-proof connection.

Dynamic Seals: For Moving Components

Dynamic seals are engineered to function where there is relative motion, such as a rotating shaft or a reciprocating rod. Their design must manage friction and wear over millions of cycles.

PTFE lip seals are designed for rotating applications. Their flexible "lip" maintains contact with the shaft to contain fluids and exclude contaminants while minimizing friction.

PTFE piston seals are used in hydraulic and pneumatic cylinders. They seal against the cylinder bore to prevent fluid bypass as the piston moves back and forth, ensuring efficient system pressure.

The Role of Energizers in High-Performance Seals

For the most demanding applications, the inherent properties of PTFE are enhanced with an internal mechanism called an energizer, most commonly a spring.

How Spring-Energized Seals Work

A spring-energized seal uses a metallic spring embedded within the PTFE jacket. This spring provides a constant, uniform radial force against the sealing surfaces.

This mechanical force ensures a tight seal even when system pressure is low and compensates for material deformation, temperature fluctuations, and seal wear over time.

When Energizers are Critical

Spring-energized designs are necessary for applications involving extreme conditions. This includes high pressures, significant temperature variations (both high and cryogenic), and any system where long-term, reliable sealing is non-negotiable.

Understanding the Trade-offs: Material Selection

Not all PTFE is the same. The choice between a pure grade and a filled grade presents a critical trade-off between chemical purity and mechanical strength.

Virgin (Unfilled) PTFE

This is pure Polytetrafluoroethylene. It offers the highest corrosion resistance and is ideal for applications in the food, medical, or semiconductor industries where purity is paramount. However, it is softer and more prone to deformation under load.

Filled PTFE

In this type, reinforcing fillers like carbon, glass fiber, or bronze are added to the PTFE base. These fillers dramatically improve wear resistance, increase strength, and reduce the tendency to deform under pressure. The trade-off is a slight reduction in overall chemical resistance compared to virgin PTFE.

How to Select the Right PTFE Seal

Choosing the correct seal begins with a clear understanding of your application's primary demand.

- If your primary focus is sealing stationary flanges or connections: Simple static seals like PTFE gaskets or washers are your most reliable and cost-effective solution.

- If you are sealing a rotating shaft or a moving piston: You require a dynamic seal, such as a lip or piston seal, designed to handle motion and minimize friction.

- If your application involves extreme temperatures, high pressures, or requires unwavering long-term reliability: A spring-energized PTFE seal is the superior choice for maintaining a consistent sealing force.

Understanding these fundamental categories empowers you to select a seal based on its design principles, ensuring optimal performance for your specific engineering challenge.

Summary Table:

| Seal Type | Primary Function | Key Applications |

|---|---|---|

| PTFE Gaskets | Static Sealing | Piping systems, machinery housings |

| PTFE Washers | Static Sealing | Bolt/screw connections, load distribution |

| PTFE Lip Seals | Dynamic Sealing (Rotation) | Rotating shafts, contaminant exclusion |

| PTFE Piston Seals | Dynamic Sealing (Reciprocation) | Hydraulic/pneumatic cylinders |

| Spring-Energized Seals | High-Performance Sealing | Extreme pressure, temperature, and reliability demands |

Need a High-Performance PTFE Seal Solution?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard static gaskets, custom dynamic seals, or spring-energized designs for extreme conditions, we deliver reliable performance through:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Virgin PTFE for purity or filled PTFE for enhanced strength and wear resistance.

- Precision Production: Ensuring optimal sealing force and longevity.

Let us help you select or custom-design the perfect PTFE seal for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency