The primary types of PTFE lined valves are Ball, Butterfly, Plug, Diaphragm, and Check valves. Each is designed with a specific mechanical operation to control flow, but all are lined with Polytetrafluoroethylene (PTFE) to provide exceptional resistance against highly corrosive or high-purity media. The choice among them depends entirely on your application's specific needs, such as the type of flow control required, pipe diameter, and cleanliness standards.

The core challenge isn't just knowing that PTFE provides chemical resistance; it's about matching the mechanical function of the valve (ball, disc, plug, or diaphragm) to the specific demands of your process pipeline.

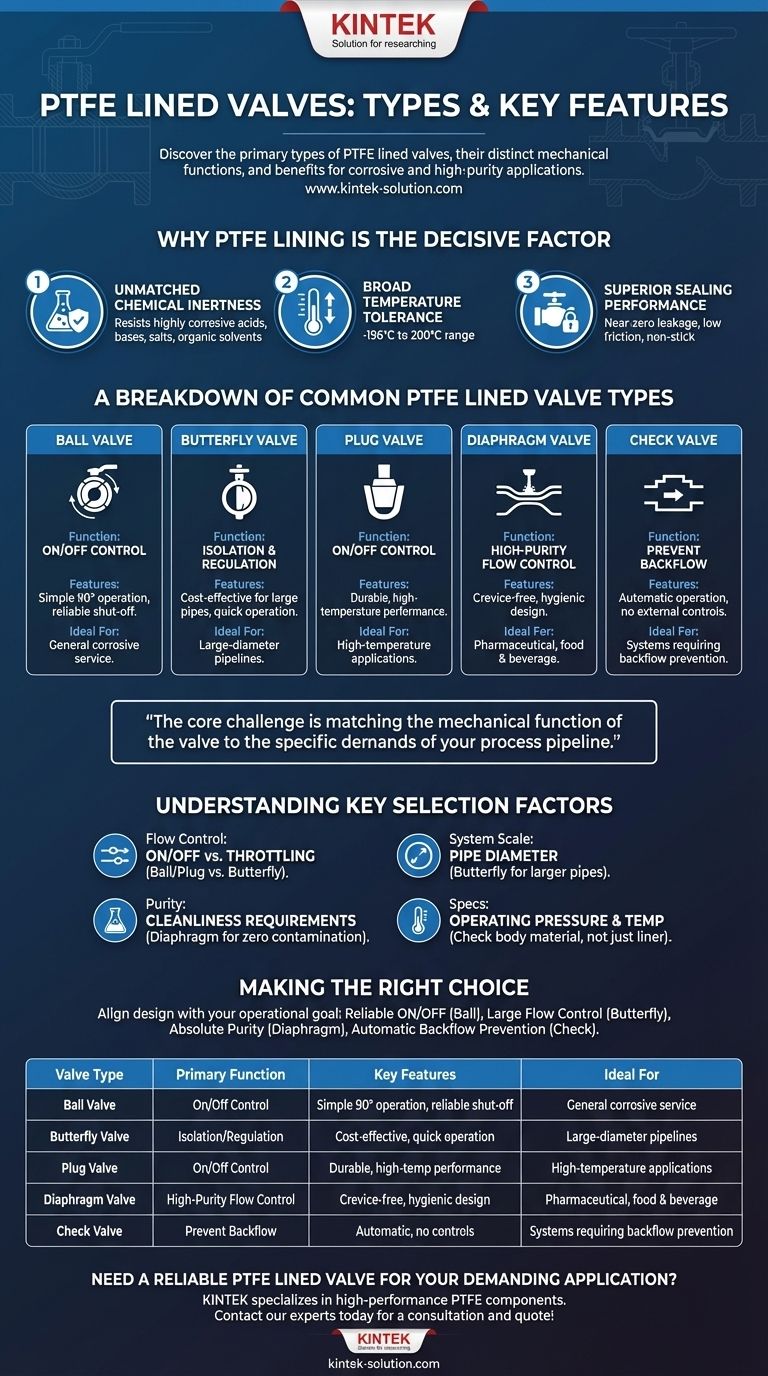

Why PTFE Lining is the Decisive Factor

Before comparing valve types, it's crucial to understand why PTFE is the material of choice for demanding applications. Its properties are what make these valves uniquely suited for handling aggressive substances.

Unmatched Chemical Inertness

PTFE is a fluoropolymer that is chemically inert to almost all industrial chemicals. This includes highly corrosive acids, bases, salts, and organic solvents. This property ensures the integrity of both the valve and the media passing through it, preventing contamination and corrosion.

Broad Temperature Tolerance

PTFE linings perform reliably across a wide operational temperature range, typically from cryogenic levels (-196°C) up to 200°C. This stability makes them suitable for processes that experience significant temperature fluctuations without compromising the valve's sealing performance.

Superior Sealing Performance

The non-stick, low-friction surface of PTFE contributes to excellent sealing capabilities, often achieving near-zero leakage. This is critical in applications involving hazardous materials or where process efficiency depends on tight shut-off.

A Breakdown of Common PTFE Lined Valve Types

While the PTFE liner provides the chemical protection, the valve's mechanical design dictates its function. Each type is engineered for a different purpose.

PTFE Lined Ball Valve

This is one of the most common types, used primarily for on/off control. A rotating ball with a bore through the center either allows or blocks flow. When the bore is aligned with the pipe, the valve is open; a 90-degree turn closes it completely.

PTFE Lined Butterfly Valve

Ideal for isolating or regulating flow, especially in large-diameter pipelines. A disc mounted on a stem rotates within the flow path. This design is simple, cost-effective, and allows for quick opening and closing.

PTFE Lined Plug Valve

Functionally similar to a ball valve, this type uses a cylindrical or tapered plug with a bore. It is also primarily used for on/off service and is particularly noted for its durability in high-temperature applications.

PTFE Lined Diaphragm Valve

This valve is engineered for applications where purity is paramount, such as in the pharmaceutical or food and beverage industries. Its crevice-free design isolates the process media from the valve's mechanical components, eliminating potential contamination points.

PTFE Lined Check Valve

This is a passive, single-purpose valve designed solely to prevent reverse flow (backflow) in a pipeline. It operates automatically based on pressure differentials and has no external controls.

Understanding the Key Selection Factors

Choosing the correct valve requires moving beyond the liner material and analyzing the operational needs of your system. Making the wrong mechanical choice can lead to inefficient operation or premature failure.

Flow Control: On/Off vs. Throttling

Your first consideration is how you need to control the flow. Ball and plug valves excel at simple, reliable on/off service but are generally poor for throttling or regulating flow.

In contrast, butterfly valves can be used for both isolation and regulation, offering more operational flexibility.

System Scale and Pipe Diameter

For larger pipes (typically 3" and above), butterfly valves are often the most practical and cost-effective solution due to their relatively simple construction and lower weight compared to a similarly sized ball valve.

Purity and Cleanliness Requirements

If your process cannot tolerate any contamination or requires frequent, easy cleaning, the diaphragm valve is the definitive choice. Its design eliminates areas where media can become trapped and stagnate.

Operating Pressure and Temperature

While the PTFE liner has excellent temperature resistance, the valve's overall pressure and temperature rating is determined by its body material (e.g., ductile iron, carbon steel, stainless steel) and construction. Always verify that the complete valve assembly meets your system's specifications.

Making the Right Choice for Your Application

Selecting the ideal valve is a matter of aligning its design with your primary operational goal.

- If your primary focus is reliable on/off control for corrosive media: A PTFE lined ball valve is your most robust and straightforward solution.

- If your primary focus is flow control in large pipelines where cost is a factor: A PTFE lined butterfly valve offers the best balance of performance, versatility, and economy.

- If your primary focus is absolute purity in a hygienic or sanitary process: The crevice-free design of a PTFE lined diaphragm valve is non-negotiable.

- If your primary focus is simply to prevent backflow automatically: A PTFE lined check valve is the correct and only component for the job.

By matching the valve’s mechanical function to your specific process need, you ensure optimal performance, safety, and longevity for your system.

Summary Table:

| Valve Type | Primary Function | Key Features | Ideal For |

|---|---|---|---|

| Ball Valve | On/Off Control | Simple 90° operation, reliable shut-off | General corrosive service |

| Butterfly Valve | Isolation/Regulation | Cost-effective for large pipes, quick operation | Large-diameter pipelines |

| Plug Valve | On/Off Control | Durable, high-temperature performance | High-temperature applications |

| Diaphragm Valve | High-Purity Flow Control | Crevice-free, hygienic design | Pharmaceutical, food & beverage |

| Check Valve | Prevent Backflow | Automatic operation, no external controls | Systems requiring backflow prevention |

Need a Reliable PTFE Lined Valve for Your Demanding Application?

Selecting the right valve is critical for the safety and efficiency of your process. KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated PTFE lined valves, seals, liners, and labware.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions that prioritize precision and chemical resistance—from prototypes to high-volume orders.

Let our experts help you specify the perfect valve for your system. Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability