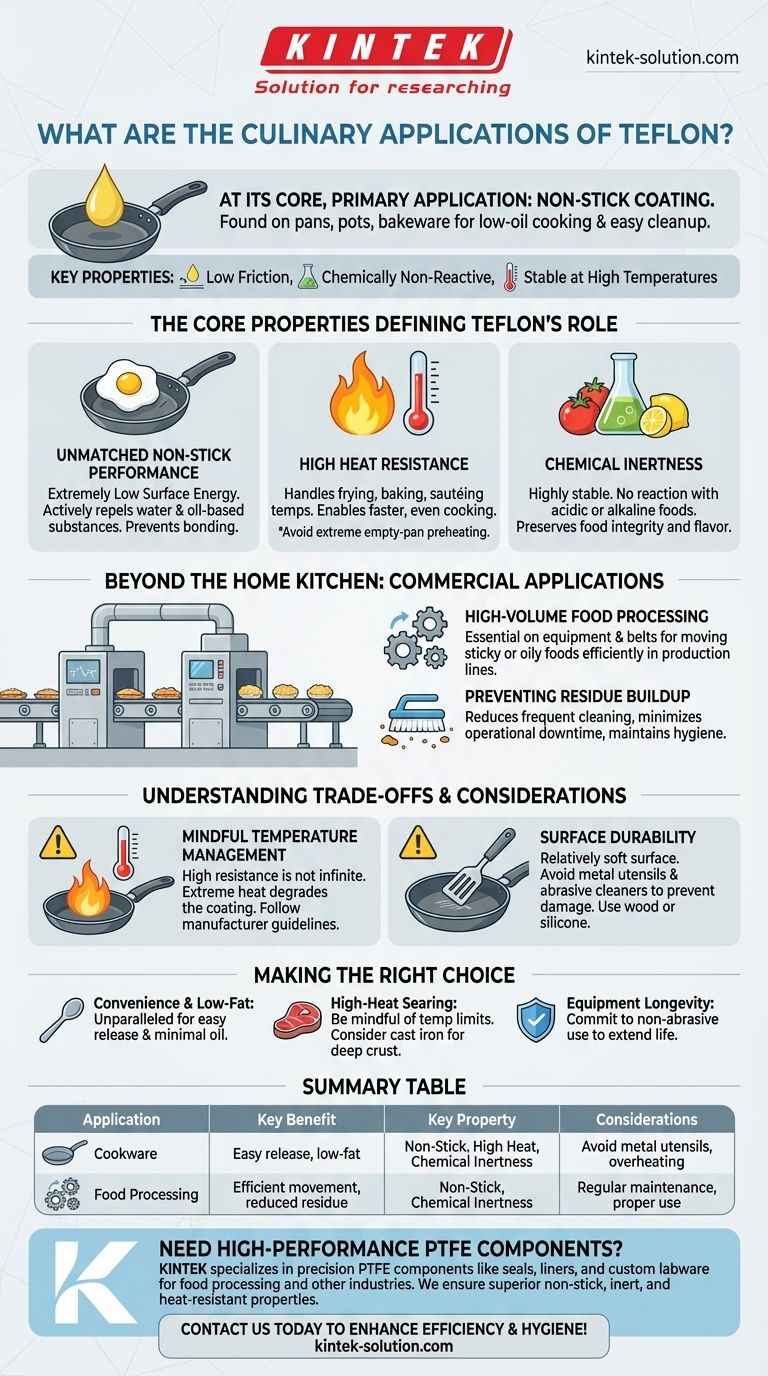

At its core, Teflon's primary culinary application is as a non-stick coating. You will find it on everyday items like frying pans, pots, and bakeware. This coating is valued because it allows for cooking with less oil and dramatically simplifies cleanup by preventing food from sticking to the surface.

The true value of Teflon in any culinary setting—from a home kitchen to a commercial food plant—stems from a unique combination of three properties: it is extremely slippery (low friction), chemically non-reactive, and stable at high temperatures.

The Core Properties Defining Teflon's Culinary Role

To understand why Teflon (the brand name for Polytetrafluoroethylene or PTFE) is so prevalent, we must look at the specific material characteristics that make it uniquely suited for cooking.

Unmatched Non-Stick Performance

Teflon’s most famous quality is its non-stick surface. This is due to its extremely low surface energy, which means it actively repels both water and oil-based substances.

This property is what prevents everything from eggs to fish from bonding to the pan, allowing food to slide off easily.

High Heat Resistance

Cookware must be able to withstand high temperatures without breaking down. Teflon excels here, as it can handle the typical heat levels used for frying, baking, and sautéing.

This efficient heat transfer also contributes to faster and more even cooking, helping to eliminate hot spots that can burn food while other parts are undercooked.

Chemical Inertness

Teflon is a highly stable and non-reactive material. This is critical in the kitchen, as it means the coating will not react with acidic foods like tomatoes or alkaline ingredients.

This chemical inertness ensures that the cookware does not corrode or impart any unwanted flavors into your food, preserving the integrity of your ingredients.

Beyond the Home Kitchen: Commercial Applications

While most people associate Teflon with household pans, its properties are also leveraged in large-scale food production.

High-Volume Food Processing

In commercial settings, you will find Teflon coatings on processing equipment and conveyor belts. Its non-stick nature is essential for moving sticky or oily foods efficiently through a production line.

Preventing Residue Buildup

By preventing food residues from sticking to machinery, Teflon coatings reduce the need for frequent and intensive cleaning. This minimizes operational downtime and helps maintain a more hygienic environment.

Understanding the Trade-offs and Considerations

No material is without its limitations. Being an effective technical advisor means understanding the practical trade-offs involved in using Teflon-coated cookware.

Mindful Temperature Management

While Teflon has high heat resistance, it is not infinite. Exposing the cookware to extreme temperatures well beyond normal cooking ranges (e.g., heating an empty pan on high for an extended period) can cause the coating to degrade.

Following manufacturer guidelines and avoiding excessive, empty-pan preheating is key to maintaining the coating's integrity and safety.

Surface Durability

The same properties that make Teflon non-stick also make its surface relatively soft compared to materials like cast iron or stainless steel.

Using metal utensils, abrasive scouring pads, or harsh detergents can scratch and damage the coating. This will diminish its non-stick performance over time. It is always best to use wood, silicone, or plastic utensils.

Making the Right Choice for Your Goal

Your decision to use Teflon should be based on your specific cooking needs and style.

- If your primary focus is convenience and low-fat cooking: Teflon is an unparalleled choice for its easy food release and minimal need for butter or oil.

- If your primary focus is high-heat searing (e.g., steaks): Be mindful of temperature limits. While Teflon can handle high heat, materials like cast iron or stainless steel are often preferred for achieving a deep crust.

- If your primary focus is equipment longevity: Commit to using non-abrasive utensils and cleaning methods to protect the coating and extend the life of your cookware.

Ultimately, understanding Teflon's unique properties allows you to leverage its benefits for easier, more efficient cooking.

Summary Table:

| Application | Key Benefit | Common Examples |

|---|---|---|

| Home & Commercial Cookware | Easy food release, low-fat cooking, simple cleanup | Frying pans, bakeware, pots |

| Food Processing Equipment | Efficient movement of sticky foods, reduced residue buildup | Conveyor belts, processing machinery |

| Key Properties | Why It Matters | Considerations |

| Non-Stick Surface | Prevents food from sticking | Avoid metal utensils to prevent scratches |

| High Heat Resistance | Withstands typical cooking temperatures | Do not overheat empty pans |

| Chemical Inertness | Won't react with acidic/alkaline foods, no flavor transfer | Preserves food integrity |

Need high-performance PTFE components for your food processing equipment or specialized applications?

At KINTEK, we specialize in the precision manufacturing of PTFE components like seals, liners, and custom labware. Our expertise ensures the superior non-stick, chemically inert, and high-temperature resistant properties you rely on are built into every part.

We serve a wide range of industries, including food processing, and offer custom fabrication from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your equipment's efficiency and hygiene!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance