PTFE rotary seals are required in demanding operational environments where traditional elastomeric (rubber) seals would quickly fail. These conditions include extreme high or low temperatures, high rotational speeds, intense system pressure, and exposure to aggressive chemicals or abrasive media. They are the specified solution for applications demanding long service life, low friction, or the ability to run dry without damage.

The decision to use a PTFE rotary seal is an engineering choice made when the performance limits of a standard elastomeric seal have been met or exceeded. It is not a direct replacement, but a targeted upgrade for applications where temperature, speed, pressure, or chemical compatibility are the primary points of failure.

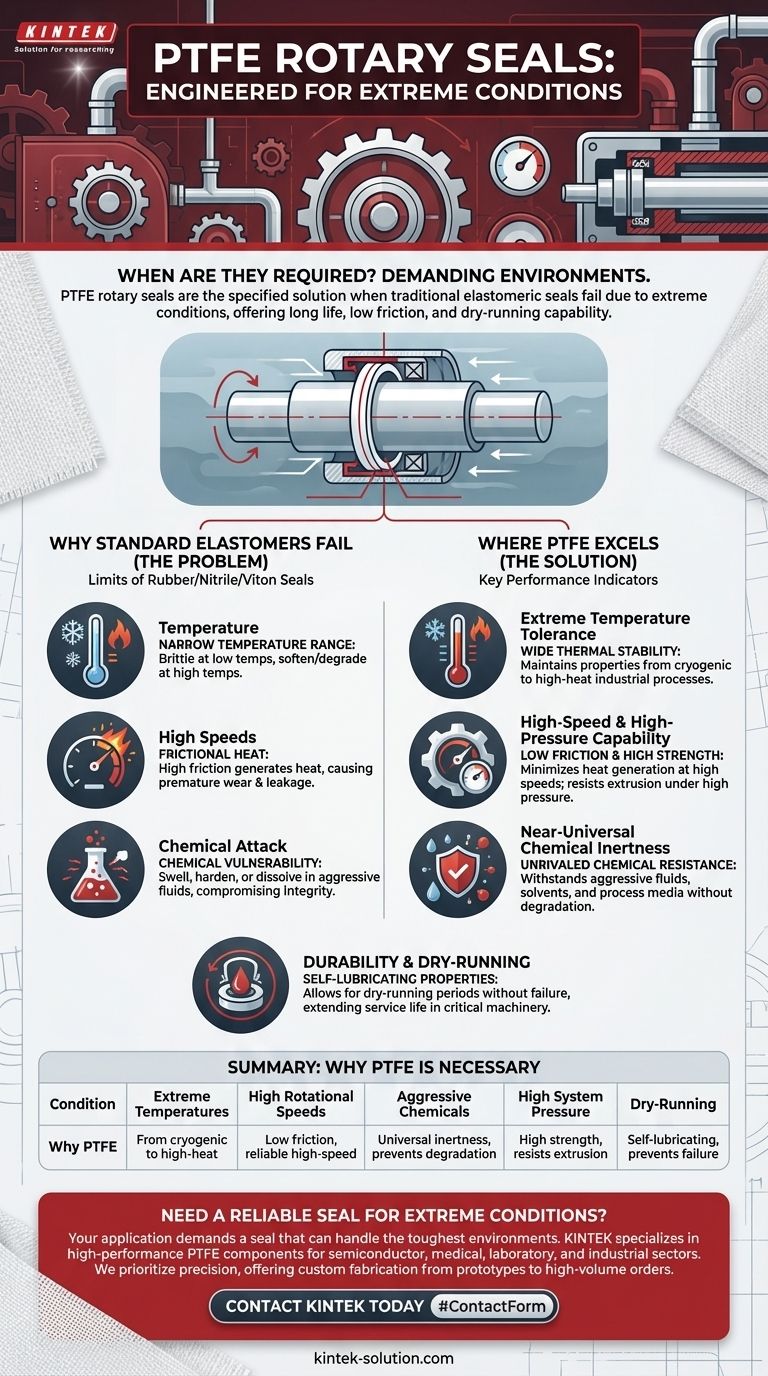

Why Standard Elastomeric Seals Have Limits

To understand when to specify PTFE, we must first recognize the inherent limitations of conventional rubber seals, such as Nitrile or Viton. While excellent for general-purpose use, they have clear operational boundaries.

The Problem with Temperature

Elastomeric compounds have a relatively narrow effective temperature range. At low temperatures, they become brittle and lose their ability to flex, while at high temperatures, they can soften, degrade, or permanently set, leading to seal failure.

The Challenge of High Speeds

High surface speeds generate significant frictional heat. This heat can cause the elastomer to break down, leading to premature wear and leakage. The material's higher coefficient of friction exacerbates this issue.

The Threat of Chemical Attack

While some elastomers offer good chemical resistance, they can swell, harden, or dissolve when exposed to aggressive or incompatible fluids. This degradation compromises the seal's integrity and can contaminate the system media.

Where PTFE Excels: Key Performance Indicators

PTFE seals, often made from advanced composites and energized with an O-ring or metal spring, are engineered specifically to overcome the limitations of rubber.

Extreme Temperature Tolerance

PTFE maintains its properties across an exceptionally wide temperature range, making it suitable for everything from cryogenic applications to high-heat industrial processes where elastomers would instantly fail.

High-Speed and High-Pressure Capability

The very low coefficient of friction inherent to PTFE minimizes heat generation, even at high rotational speeds. This "slipperiness" allows the seal to run cooler and last longer. The material's strength also resists extrusion under high pressure.

Near-Universal Chemical Inertness

PTFE is one of the most chemically inert materials available. It can withstand a vast array of aggressive fluids, solvents, and process media without degrading, making it essential for the pharmaceutical, chemical, and food processing industries.

Durability and Dry-Running

PTFE's self-lubricating properties allow it to run dry for periods without catastrophic failure, a condition that would destroy an elastomeric seal. This toughness contributes to a significantly longer service life in demanding machinery like compressors, motors, and gearboxes.

Understanding the Trade-offs and Considerations

While powerful, PTFE seals are a specific solution and not a universal drop-in for every application. Understanding their context is critical for success.

System Design and Installation

PTFE seals are less forgiving of hardware imperfections than soft elastomers. The shaft's surface finish and hardness are critical for optimal performance. Furthermore, many designs rely on an O-ring "energizer" to provide the initial sealing force, adding a component to the system.

Material Selection

"PTFE" is a family of materials. The seal's performance is heavily dependent on the specific fillers (like carbon, glass, or bronze) used in the composite. Selecting the wrong compound for the application can lead to suboptimal results.

Cost vs. Lifecycle Value

PTFE seals typically have a higher initial cost than standard elastomeric seals. This cost is justified by their extended lifespan, reduced maintenance requirements, and the prevention of costly downtime in critical machinery.

Making the Right Choice for Your Application

Selecting the correct seal technology hinges on identifying the primary stressor in your system.

- If your primary focus is extreme temperature or cryogenic service: PTFE is essential due to its stability across a vast thermal range where rubber cannot perform.

- If your primary focus is high rotational speed: PTFE's low-friction properties will minimize heat generation and wear, dramatically outperforming elastomeric seals.

- If your primary focus is aggressive chemical exposure: PTFE's chemical inertness is non-negotiable for preventing seal degradation and ensuring system purity.

- If your primary focus is longevity and preventing downtime: The durability and wear resistance of PTFE justifies its initial cost in critical equipment like compressors, pumps, and gearboxes.

Ultimately, specifying a PTFE rotary seal is an investment in reliability for machinery operating at the edge of performance.

Summary Table:

| Condition | Why PTFE is Necessary |

|---|---|

| Extreme Temperatures | Maintains integrity from cryogenic to high-heat processes where elastomers fail. |

| High Rotational Speeds | Low friction minimizes heat generation and wear, enabling reliable high-speed operation. |

| Aggressive Chemicals | Near-universal chemical inertness prevents degradation from solvents and harsh media. |

| High System Pressure | High strength resists extrusion, ensuring a reliable seal under intense pressure. |

| Dry-Running or Low Lubrication | Self-lubricating properties allow for periods of dry operation without catastrophic failure. |

Need a reliable seal for extreme conditions?

Your application demands a seal that can handle the toughest environments. KINTEK specializes in manufacturing high-performance PTFE components, including custom rotary seals, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision and offer custom fabrication from prototypes to high-volume orders to ensure your equipment operates reliably.

Contact KINTEK today to discuss your specific requirements and let our experts provide a sealing solution that extends your machinery's lifespan and prevents costly downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance