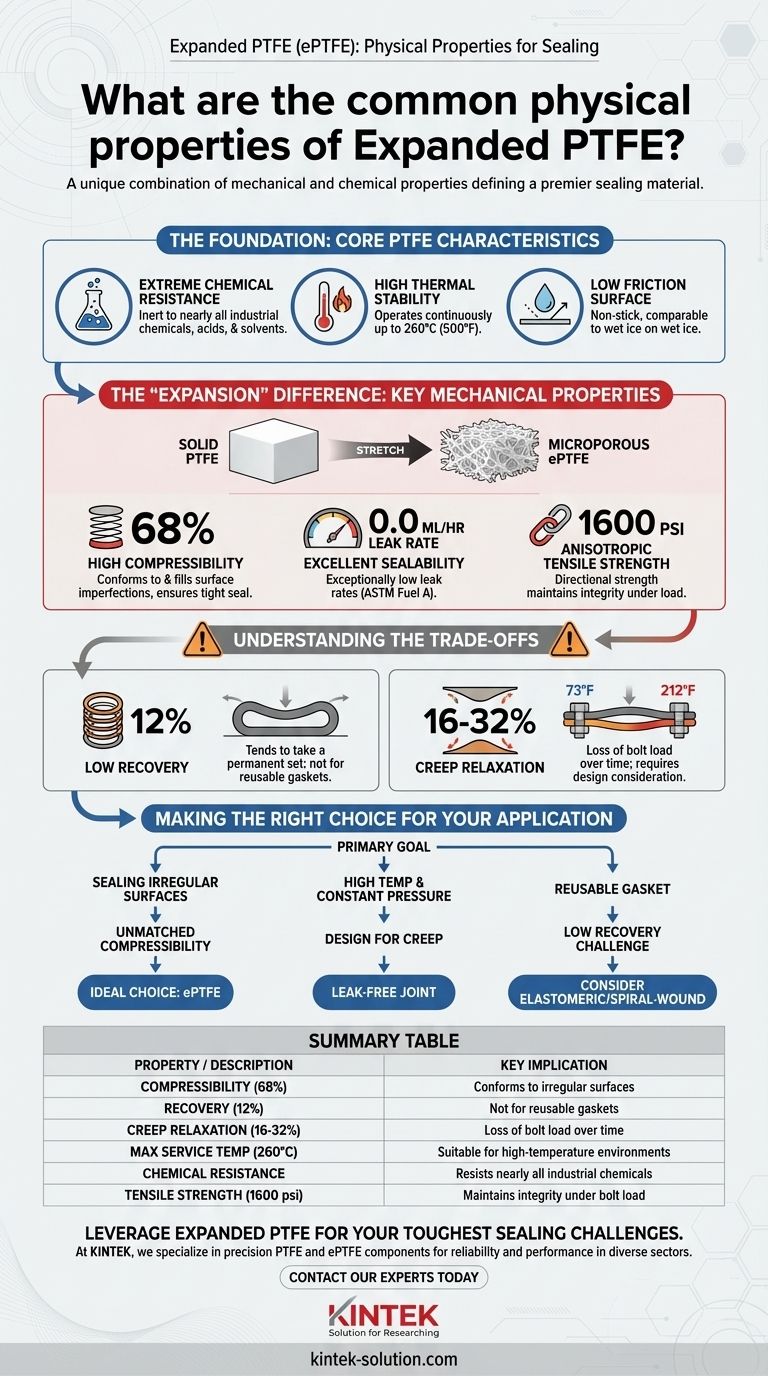

At its core, Expanded PTFE (ePTFE) is defined by a unique combination of mechanical and chemical properties that make it a premier sealing material. Key physical metrics include a high compressibility of 68%, low recovery of 12%, and significant creep relaxation (16-32% depending on temperature). It also inherits the foundational characteristics of standard PTFE, such as extreme chemical inertness and a high temperature tolerance up to 260°C (500°F).

The defining characteristic of Expanded PTFE is its ability to combine the exceptional chemical and thermal resistance of standard PTFE with a soft, conformable structure. This makes it an unparalleled material for creating a tight seal on irregular or damaged surfaces, though this comes with trade-offs in recovery and creep resistance.

The Foundation: Core PTFE Characteristics

Expanded PTFE is manufactured from standard Polytetrafluoroethylene (PTFE). It therefore retains all the foundational properties that make PTFE such a versatile and resilient polymer.

Extreme Chemical Resistance

PTFE is an inert material, meaning it is non-reactive to nearly all common industrial chemicals. This includes aggressive acids, bases, and solvents. This property makes ePTFE suitable for sealing systems that handle corrosive media.

High Thermal Stability

ePTFE can operate continuously at temperatures up to 260°C (500°F) without degrading. This high thermal stability allows it to be used in a wide range of demanding industrial applications.

Low Friction Surface

Known for its exceptionally low coefficient of friction, PTFE has a non-stick surface comparable to wet ice on wet ice. While less critical for sealing, this property contributes to its overall material profile.

The "Expansion" Difference: Key Mechanical Properties

The expansion process transforms solid PTFE into a microporous, fibrous structure. This fundamentally changes its mechanical behavior, turning it from a rigid plastic into a soft, conformable gasketing material.

High Compressibility (68%)

This is the most significant mechanical advantage of ePTFE. Its soft, spongy nature allows it to easily conform to and fill in surface imperfections, scratches, and slight misalignments in flanges. This ensures an extremely tight seal even on less-than-perfect surfaces.

Excellent Sealability

The high compressibility directly translates to outstanding sealing performance. Test data shows exceptionally low leak rates, such as 0.0 ml/hr for ASTM Fuel A and 0.16 ml/hr for nitrogen, demonstrating its ability to create a gas-tight seal under pressure.

Anisotropic Tensile Strength (1600 psi)

The expansion process orients the fibrous structure, giving the material directional strength. A tensile strength of 1600 psi "across the grain" indicates its resistance to being pulled apart, a critical factor for maintaining integrity under bolt load.

Understanding the Trade-offs

No material is perfect. To use ePTFE effectively, you must understand its inherent limitations, which are direct consequences of its soft, conformable structure.

Low Recovery (12%)

Recovery is a material's ability to spring back to its original thickness after being compressed. With a low recovery of only 12%, ePTFE tends to take a permanent set once compressed. This means it is generally not suitable for applications requiring a reusable gasket or for joints that frequently open and close.

Creep Relaxation (16-32%)

Creep is the tendency of a material to deform slowly under constant stress. In gasketing, this results in a loss of bolt load and sealing pressure over time. ePTFE exhibits 16% creep at 73°F and a more significant 32% at 212°F. This factor must be accounted for during joint design and may require specific torquing procedures or periodic re-torquing.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is sealing irregular or damaged surfaces: The unmatched compressibility of ePTFE makes it the ideal choice to create a reliable seal where other gaskets would fail.

- If your application involves high temperatures and constant pressure: You must design for ePTFE's creep relaxation to ensure a long-term, leak-free joint.

- If you need a reusable gasket for frequent service: The low recovery of ePTFE makes it a poor choice; consider an elastomeric or spiral-wound gasket instead.

Ultimately, understanding these distinct physical properties empowers you to leverage Expanded PTFE's strengths for creating exceptionally reliable seals in demanding environments.

Summary Table:

| Property | Value / Description | Key Implication |

|---|---|---|

| Compressibility | 68% | Conforms to irregular surfaces for a superior seal |

| Recovery | 12% | Not suitable for reusable gaskets; takes a permanent set |

| Creep Relaxation | 16% (73°F) to 32% (212°F) | Loss of bolt load over time; requires design consideration |

| Max Service Temperature | 260°C (500°F) | Suitable for high-temperature environments |

| Chemical Resistance | Excellent (inherited from PTFE) | Resists nearly all industrial chemicals, acids, and solvents |

| Tensile Strength | 1600 psi (anisotropic) | Maintains integrity under bolt load |

Leverage the unique properties of Expanded PTFE for your most demanding sealing challenges.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE and ePTFE components, including custom seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution engineered for reliability and performance.

Ready to solve your toughest sealing problems? Contact our experts today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments