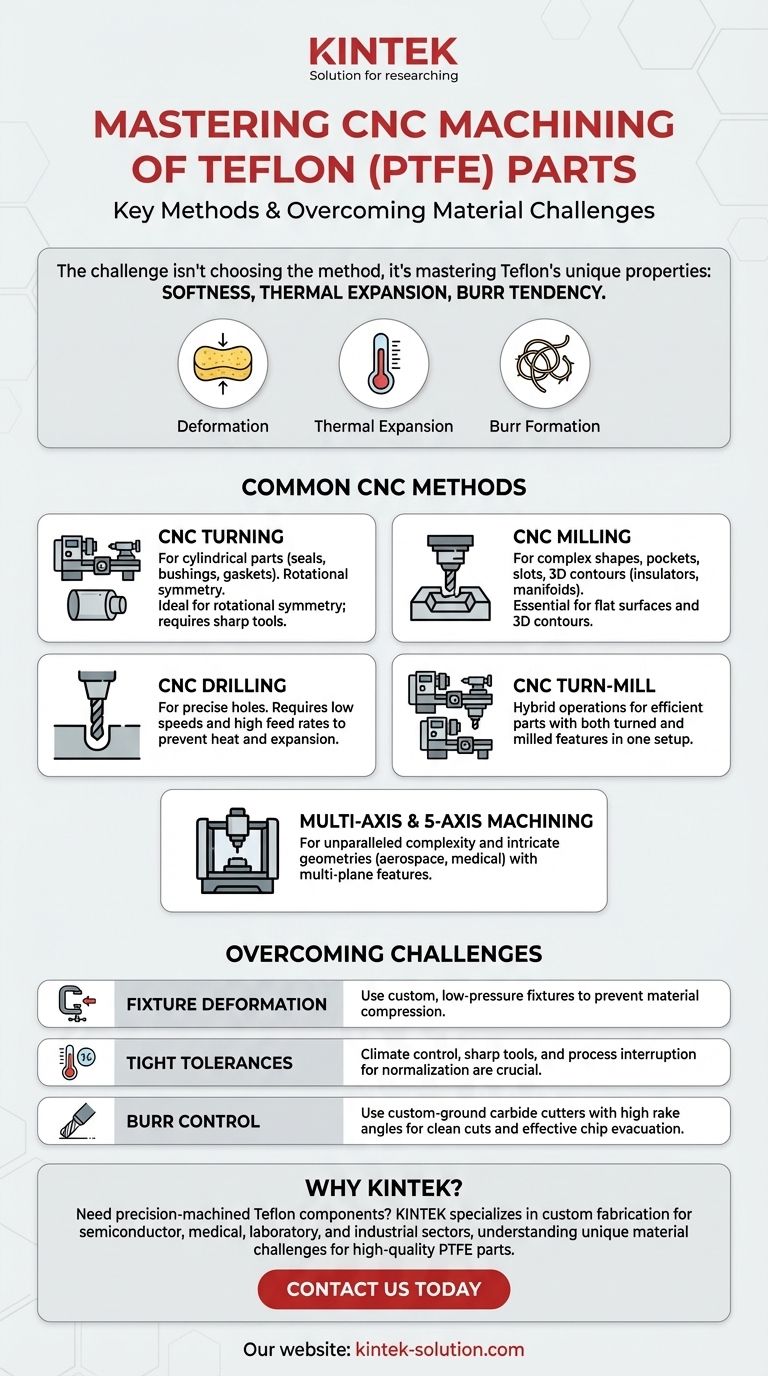

The primary CNC machining methods for Teflon are CNC turning, milling, drilling, turn-milling, and multi-axis machining. Each technique is selected based on the desired geometry of the final part, from simple cylindrical seals to highly complex components for aerospace or medical applications. Successfully machining Teflon, however, depends less on the method itself and more on managing the material's unique properties.

The challenge isn't choosing between turning or milling; it's mastering how to apply these standard methods to a material that is uniquely soft, expands significantly with heat, and deforms easily under pressure.

Why Teflon Requires a Specialized Approach

Before selecting a machining method, you must understand the material's behavior. Teflon (PTFE) is not like machining aluminum or steel; its properties dictate every decision in the process.

The Impact of Softness

Teflon's inherent softness and low friction make it prone to deforming under the pressure of clamps or fixtures. Over-tightening can easily ruin a part's final dimensions.

The Challenge of Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even a small amount of heat generated from cutting tools can cause the material to expand, making it extremely difficult to hold tight tolerances.

The Tendency to Form Burrs

Instead of creating clean chips like metal, Teflon tends to produce stringy, gummy swarf and form burrs along cut edges. This requires exceptionally sharp tooling and specific cutting parameters to achieve a clean finish.

A Breakdown of Common CNC Methods

Each CNC method is suited for creating different types of geometries. The choice is driven entirely by the final part design.

CNC Turning: For Cylindrical Parts

CNC turning is used for parts with rotational symmetry. The Teflon workpiece rotates while a stationary cutting tool removes material, making it ideal for creating seals, gaskets, bushings, and hollow valve components.

CNC Milling: For Complex Shapes and Features

In CNC milling, the cutting tool rotates and moves across a stationary workpiece. This method is used to create flat surfaces, pockets, slots, and complex 3D contours on parts like insulators, manifolds, and custom blocks.

CNC Drilling: For Precise Holes

While a function of both mills and lathes, CNC drilling requires special attention with Teflon. Low speeds and high feed rates are crucial to prevent heat buildup, which can cause the material around the hole to expand and compromise dimensional accuracy.

CNC Turn-Mill: For Efficient, Hybrid Operations

Turn-mill machines combine the capabilities of both turning and milling in a single setup. This is highly efficient for complex parts that have both cylindrical features and milled details, as it reduces handling and improves accuracy.

Multi-Axis & 5-Axis Machining: For Unparalleled Complexity

For the most intricate geometries with undercuts or features on multiple faces, multi-axis machining is essential. A 5-axis machine can move the tool and the part simultaneously, enabling the creation of complex aerospace components and medical devices with exceptional precision.

Key Challenges to Overcome

Successfully machining Teflon means directly addressing its inherent material challenges. Ignoring these will lead to scrapped parts and failed projects.

Challenge 1: Deformation During Fixturing

Because Teflon is so soft, standard clamping methods can easily compress the material, leading to inaccurate final parts once the pressure is released. Custom, low-pressure fixtures are often required.

Challenge 2: Maintaining Tight Tolerances

The combination of thermal expansion and stress creep makes holding tight tolerances the single greatest challenge. This requires a climate-controlled environment, sharp tools to minimize heat, and often a process of machining, letting the part rest and normalize, and then performing a final finishing pass.

Challenge 3: Burr Control and Chip Evacuation

Poor chip control and burr formation result in a poor-quality finish. This is managed by using custom-ground carbide cutters with high rake and clearance angles designed specifically to slice the material cleanly and evacuate chips effectively.

Selecting the Right Method for Your Part

Your part's design dictates the best machining strategy. Use these guidelines to make an informed decision.

- If your primary focus is cylindrical parts like seals or bushings: CNC turning is the most direct and cost-effective method.

- If your primary focus is parts with flat surfaces, pockets, or non-symmetrical shapes: CNC milling provides the necessary capability for these features.

- If your primary focus is parts with intricate curves or features on multiple planes: Multi-axis or 5-axis machining is necessary to achieve the required precision without multiple, error-prone setups.

- If your primary focus is efficiency for parts with both turned and milled features: A turn-mill center is the ideal choice to combine operations and ensure accuracy.

Ultimately, success with Teflon comes from respecting the material's properties and adapting standard machining processes to accommodate them.

Summary Table:

| Machining Method | Best For | Key Considerations |

|---|---|---|

| CNC Turning | Cylindrical parts (seals, bushings) | Ideal for rotational symmetry; requires sharp tools. |

| CNC Milling | Complex shapes, pockets, slots | Essential for flat surfaces and 3D contours. |

| CNC Drilling | Precise holes | Low speeds and high feed rates to prevent heat. |

| Turn-Mill | Hybrid parts (turned + milled features) | Increases efficiency and accuracy in one setup. |

| Multi-Axis (5-Axis) | Highly complex geometries (aerospace, medical) | Necessary for undercuts and multi-plane features. |

Need precision-machined Teflon components? Successfully producing high-quality PTFE parts requires a partner who understands the material's unique challenges, from thermal expansion to burr control. KINTEK specializes in the custom fabrication of PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with specialized expertise to handle everything from prototypes to high-volume orders.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments