In short, virgin grade PTFE gaskets are defined by their 100% pure composition. This purity gives them a unique combination of exceptional chemical resistance, excellent electrical insulation, and a non-contaminating surface ideal for sensitive applications. They are extremely soft and formable, allowing them to create a tight seal, and are easily identified by their distinct bright white color.

While virgin PTFE offers unmatched chemical inertness and purity, its core strength—extreme softness—is also the source of its primary limitation. The key is to understand how this softness impacts its performance under mechanical stress and pressure.

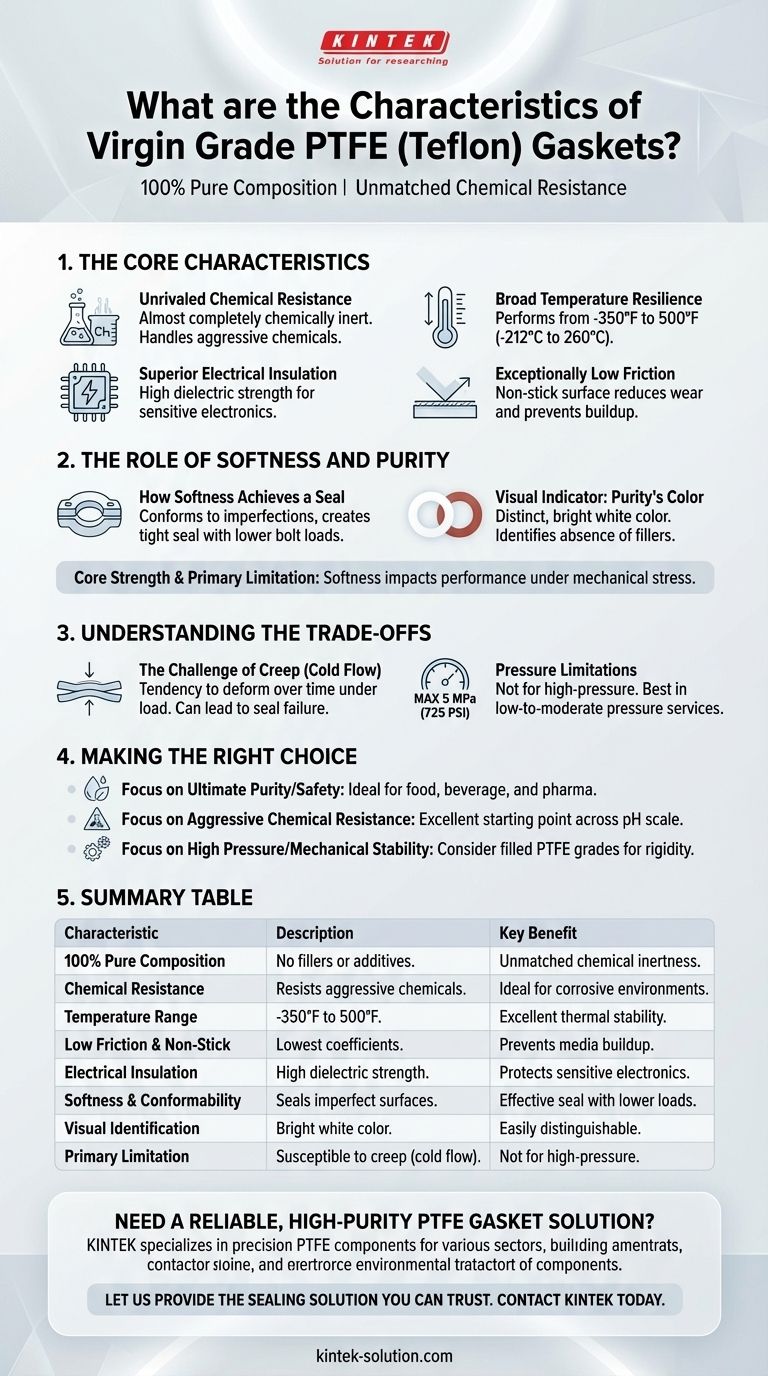

The Core Characteristics of Virgin PTFE

Virgin Polytetrafluoroethylene (PTFE) is a fluoropolymer with no fillers or additives. This simple composition is the source of its most valued properties.

Unrivaled Chemical Resistance

Because it is 100% pure PTFE, this gasket material is almost completely chemically inert. It can handle a wider range of aggressive chemicals than nearly any other polymer.

This makes it a default choice for sealing in highly corrosive environments found in chemical processing plants.

Broad Temperature Resilience

Virgin PTFE maintains its integrity and mechanical strength across an exceptionally wide operational temperature range.

It can reliably perform in conditions from approximately -350°F to 500°F (-212°C to 260°C), resisting both extreme cold and high heat without becoming brittle or degrading.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength and non-conductive properties.

This characteristic makes virgin PTFE gaskets essential for use in sensitive electronic components, circuit boards, and other electrical equipment where isolating currents is critical.

Exceptionally Low Friction

The material has one of the lowest coefficients of friction of any solid, creating a non-stick, non-adhesive surface.

This low-friction nature reduces wear and tear during installation and removal, prevents process media from building up on the gasket surface, and ensures a clean seal.

The Role of Softness and Purity

The defining physical trait of virgin PTFE is its softness, which is a direct result of its pure, unfilled structure. This has direct implications for both performance and identification.

How Softness Achieves a Seal

Virgin PTFE is extremely soft and formable, allowing it to easily conform to flange imperfections and irregularities.

This ability to "flow" into minor surface defects helps create an effective, tight seal even with lower bolt loads.

The Visual Indicator: Purity's Color

The purity of virgin grade PTFE is visibly apparent. It has a distinct, bright white color.

This stands in contrast to mechanical or filled grades of PTFE, which often appear off-white, gray, or colored due to the additives mixed in to enhance certain properties.

Understanding the Trade-offs

No material is perfect for every situation. The very properties that make virgin PTFE ideal for some applications create limitations in others.

The Challenge of Creep (Cold Flow)

The softness that helps virgin PTFE seal also makes it susceptible to creep, sometimes called "cold flow."

This is the tendency of a material to slowly deform or move outward from a compressive load over time. In high-pressure applications or those with frequent temperature cycles, creep can lead to a loss of bolt torque and potential seal failure.

Pressure Limitations

Due to its propensity to creep, virgin PTFE is not suitable for high-pressure applications. It generally performs best in low-to-moderate pressure services, often cited with a maximum rating around 5 MPa (725 PSI).

For systems with higher pressures, a filled or modified PTFE gasket is a more reliable choice as the filler material provides structural reinforcement and resistance to creep.

Making the Right Choice for Your Application

Selecting the correct gasket requires balancing the need for purity and chemical resistance against the mechanical demands of the system.

- If your primary focus is ultimate purity or safety: Virgin PTFE is the definitive choice for food, beverage, and pharmaceutical applications where preventing contamination is non-negotiable.

- If your primary focus is aggressive chemical resistance: Virgin PTFE is an excellent starting point, as its inertness is nearly universal across the pH scale.

- If your primary focus is high pressure or mechanical stability: You must consider filled PTFE grades (like glass-filled or carbon-filled) to gain the necessary rigidity and creep resistance.

Ultimately, choosing virgin PTFE means prioritizing its unparalleled purity and chemical inertness for applications where mechanical stress is a secondary concern.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| 100% Pure Composition | No fillers or additives. | Unmatched chemical inertness and purity. |

| Chemical Resistance | Resists nearly all aggressive chemicals. | Ideal for corrosive environments. |

| Temperature Range | Performs from -350°F to 500°F (-212°C to 260°C). | Excellent thermal stability. |

| Low Friction & Non-Stick | One of the lowest coefficients of friction. | Prevents media buildup, easy installation. |

| Electrical Insulation | High dielectric strength. | Protects sensitive electronic components. |

| Softness & Conformability | Easily seals on imperfect surfaces. | Effective seal with lower bolt loads. |

| Visual Identification | Bright white color. | Easy to distinguish from filled grades. |

| Primary Limitation | Susceptible to creep (cold flow). | Not suitable for high-pressure applications. |

Need a Reliable, High-Purity PTFE Gasket Solution?

Virgin PTFE gaskets are essential for applications where contamination is not an option and chemical resistance is paramount. KINTEK specializes in manufacturing precision PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between purity and performance. Whether you need standard virgin PTFE gaskets or custom solutions for unique challenges, our team provides expert fabrication from prototypes to high-volume orders.

Let us provide the sealing solution you can trust. Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability