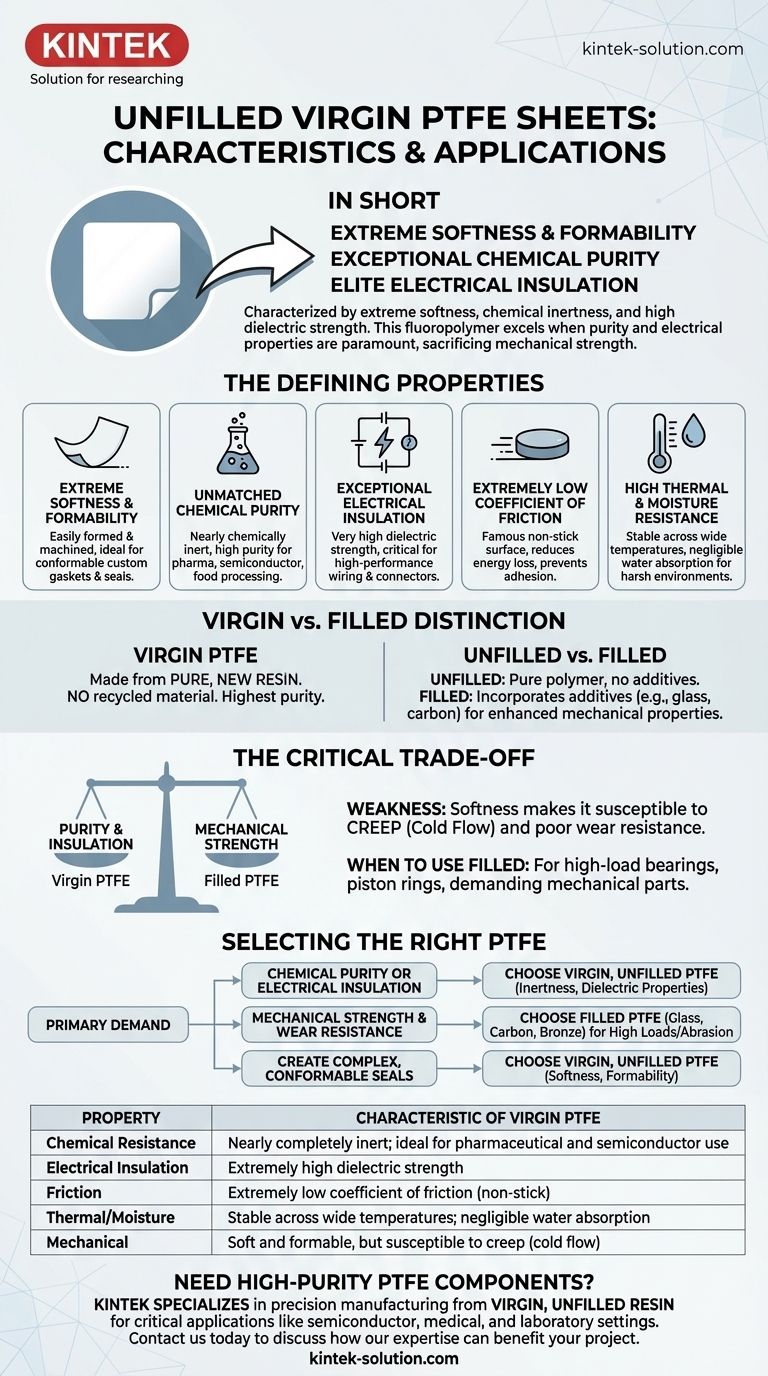

In short, unfilled PTFE sheets made from virgin resin are characterized by their extreme softness, exceptional chemical purity, and elite electrical insulation. This material is also highly formable, has a very low coefficient of friction, and exhibits strong resistance to heat and moisture.

Virgin, unfilled PTFE is the purest form of this fluoropolymer. You choose it when chemical inertness or electrical properties are non-negotiable, accepting that you are trading mechanical strength for these superior characteristics.

The Defining Properties of Virgin PTFE

Virgin, unfilled Polytetrafluoroethylene (PTFE) possesses a unique combination of traits that make it indispensable for specific, demanding applications.

Extreme Softness and Formability

Virgin PTFE is exceptionally soft and flexible. This allows it to be easily formed and machined, making it an ideal material for creating custom gaskets and seals that need to conform perfectly to surfaces.

Unmatched Chemical Purity and Resistance

This material is nearly completely chemically inert, meaning it will not react with the vast majority of industrial chemicals and solvents. This high purity makes it the standard for applications in pharmaceutical, semiconductor, and food processing industries where contamination is not an option.

Exceptional Electrical Insulation

Virgin PTFE has a very high dielectric strength, making it one of the best electrical insulators known. This property is critical for high-performance wiring, connectors, and other components in the electronics industry.

Extremely Low Coefficient of Friction

Known for its famous non-stick surface, virgin PTFE has one of the lowest coefficients of friction of any solid material. This slickness reduces energy loss in moving parts and prevents materials from adhering to its surface.

High Thermal and Moisture Resistance

The material remains stable across a wide range of temperatures and absorbs virtually no moisture. This ensures its properties remain consistent even in harsh or humid environments.

Understanding the "Virgin" vs. "Filled" Distinction

The terms "virgin" and "unfilled" are critical identifiers that define the material's performance and appropriate use. Understanding them is key to avoiding costly specification errors.

What "Virgin" PTFE Means

Virgin PTFE is manufactured from pure, new PTFE resin. It contains no recycled or reprocessed material, ensuring the highest level of purity and performance consistency. This is often contrasted with mechanical-grade or recycled PTFE, which may have lower performance specifications.

The Role of "Unfilled" vs. "Filled"

Unfilled PTFE is the pure polymer without any additives. Filled PTFE grades incorporate additives like glass, carbon, or bronze to enhance specific mechanical properties.

The Critical Trade-off: Purity vs. Mechanical Strength

The primary limitation of virgin, unfilled PTFE is its mechanical performance. This is the central trade-off you must consider.

The Weakness of Softness

Because it is so soft, virgin PTFE is susceptible to creep, or "cold flow," where the material slowly deforms under a sustained load. It also has relatively poor wear resistance compared to harder plastics.

When to Use Filled PTFE Instead

For applications requiring greater hardness, compressive strength, and durability, filled PTFE is the appropriate choice. The additives directly combat the softness of virgin PTFE, making it suitable for high-load bearings, piston rings, and other demanding mechanical parts where chemical purity is less of a concern.

Selecting the Right PTFE for Your Application

Your final choice depends entirely on the primary demand of your project.

- If your primary focus is chemical purity or electrical insulation: Choose virgin, unfilled PTFE for its unmatched inertness and dielectric properties.

- If your primary focus is mechanical strength and wear resistance: Choose a filled PTFE grade (such as glass or carbon-filled) for applications involving high loads, abrasion, or friction.

- If your primary focus is creating complex, conformable seals: The softness and formability of virgin, unfilled PTFE make it an excellent choice.

By aligning the material's distinct profile with your specific goal, you ensure optimal performance and reliability.

Summary Table:

| Property | Characteristic of Virgin PTFE |

|---|---|

| Chemical Resistance | Nearly completely inert; ideal for pharmaceutical and semiconductor use |

| Electrical Insulation | Extremely high dielectric strength |

| Friction | Extremely low coefficient of friction (non-stick) |

| Thermal/Moisture | Stable across wide temperatures; negligible water absorption |

| Mechanical | Soft and formable, but susceptible to creep (cold flow) |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—from virgin, unfilled resin for industries where chemical purity and electrical performance are paramount, such as semiconductor, medical, and laboratory settings. Our custom fabrication services ensure you get the exact solution, from prototypes to high-volume orders.

Contact us today to discuss how our virgin PTFE expertise can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability