In short, Modified Polytetrafluoroethylene (PTFE) with Premium Organic Fill is an advanced polymer composite designed for high-performance applications. It is characterized by its excellent wear resistance, enhanced compressive strength, and crucially, its ability to operate against metal components with very low abrasion. This material is visually identifiable by its distinct orange color and operates across an extremely wide temperature range.

The central advantage of this material is its ability to provide the high wear resistance of a filled PTFE without the abrasive side effects common to many mineral or inorganic fillers. It solves the critical engineering challenge of extending component life in high-load applications while simultaneously protecting expensive mating metal surfaces.

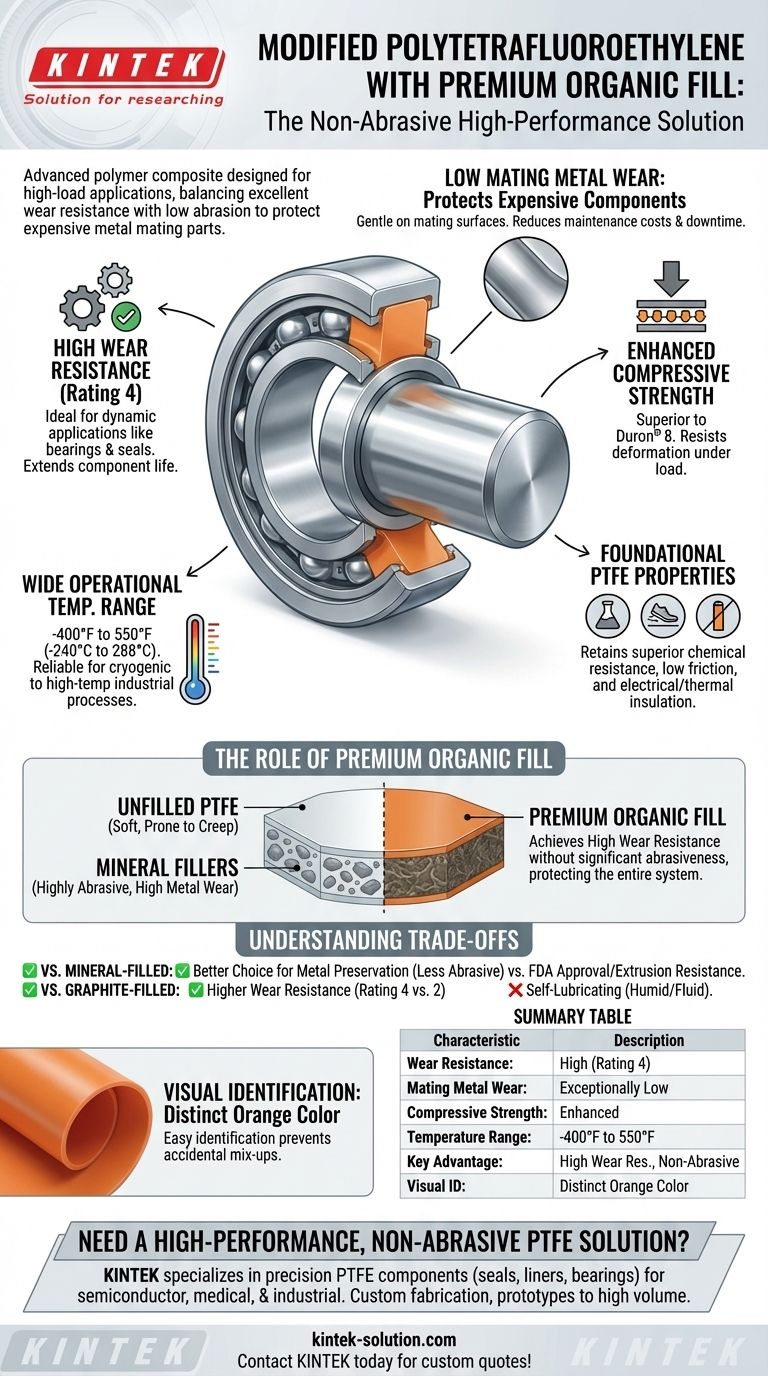

Core Performance Characteristics

High Wear Resistance

This material has a wear resistance rating of 4, placing it in the upper tier of performance for PTFE-based composites.

This high rating indicates its suitability for dynamic applications where friction and mechanical wear are primary points of failure, such as in bearings, seals, and slide pads.

Low Mating Metal Wear

This is the material's most critical feature. Unlike some mineral-filled alternatives that can be highly abrasive, the premium organic fill is gentle on mating metal surfaces.

This characteristic is essential for preserving the lifespan and integrity of expensive or hard-to-replace metal components, reducing system-wide maintenance costs and downtime.

Enhanced Compressive Strength

The addition of the organic filler significantly improves the material's ability to resist deformation under load, a known weakness of unfilled PTFE.

While specific data is not provided, it is noted to have better compressive strength than materials like Duron® 8, making it suitable for applications with higher static or dynamic loads.

Wide Operational Temperature Range

This composite performs reliably across an exceptionally broad temperature spectrum, from -400°F to 550°F (-240°C to 288°C).

This range makes it a viable option for everything from cryogenic services to high-temperature industrial processes.

Foundational PTFE Properties

As a PTFE-based material, it retains the core benefits of its base polymer. These include superior chemical resistance, low coefficient of friction, and excellent electrical and thermal insulation.

The Role of the "Premium Organic Fill"

The Problem with Unfilled PTFE

Standard or "virgin" PTFE is an excellent low-friction material, but it is mechanically soft. Under pressure, it is prone to "creep" or cold flow, causing it to deform permanently.

Fillers are added to the PTFE matrix to overcome these mechanical limitations, enhancing properties like compressive strength and wear resistance.

Organic vs. Mineral Fillers: A Key Distinction

The choice of filler material dictates the final performance trade-offs.

Mineral or inorganic fillers can dramatically increase wear resistance but often do so by being abrasive. This leads to high mating metal wear, which can damage shafts, housings, and other critical parts.

In contrast, the premium organic fill used in this material achieves high wear resistance without introducing significant abrasiveness, protecting the entire mechanical system.

Understanding the Trade-offs

vs. Mineral-Filled PTFE

A mineral-filled PTFE may offer superior extrusion resistance or meet specific regulatory requirements like FDA approval.

However, this often comes at the cost of high abrasiveness. The orange organic-filled material is the better choice when preserving the finish and lifespan of metal components is a priority.

vs. Graphite-Filled PTFE

Graphite-filled PTFE is an excellent choice for its self-lubricating properties, especially in humid or fluid applications, and it also exhibits low metal wear.

However, the organic-filled compound generally provides a higher overall wear resistance rating (4 vs. 2), making it more durable in demanding, dry-running conditions.

Visual Identification

The material's distinct orange color is a functional feature. It allows for easy and confident identification during assembly and maintenance, preventing accidental mix-ups with other off-white, tan, or black PTFE variants that have vastly different performance characteristics.

Making the Right Choice for Your Application

To select the correct material, you must first define your primary engineering goal.

- If your primary focus is preserving expensive metal components: This organic-filled PTFE is the superior choice due to its unique combination of high wear resistance and low abrasiveness.

- If your primary focus is operating in high-load, dry-running conditions: The material's enhanced compressive strength and top-tier wear rating make it ideal for this environment.

- If your primary focus is service in humid or fluid-based systems: A graphite-filled PTFE may offer more specialized performance advantages.

- If your primary focus is meeting FDA requirements for food contact: You will likely need to specify a mineral-filled PTFE and actively design for its higher abrasive effect on mating parts.

Choosing the right polymer composite is about understanding that every filler introduces a specific set of benefits and compromises.

Summary Table:

| Characteristic | Description |

|---|---|

| Wear Resistance | High wear resistance (Rating 4), ideal for dynamic applications like bearings and seals. |

| Mating Metal Wear | Exceptionally low abrasion, protecting expensive metal components and reducing system costs. |

| Compressive Strength | Enhanced strength, superior to materials like Duron® 8, for high-load applications. |

| Temperature Range | Operates reliably from -400°F to 550°F (-240°C to 288°C). |

| Key Advantage | Provides high wear resistance without the abrasive side effects of mineral/inorganic fillers. |

| Visual ID | Distinct orange color for easy identification and prevention of mix-ups. |

Need a High-Performance, Non-Abrasive PTFE Solution?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, bearings, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact Modified PTFE with Premium Organic Fill solution to extend component life and protect your mating metal surfaces.

Contact KINTEB today to discuss your application requirements and receive a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications