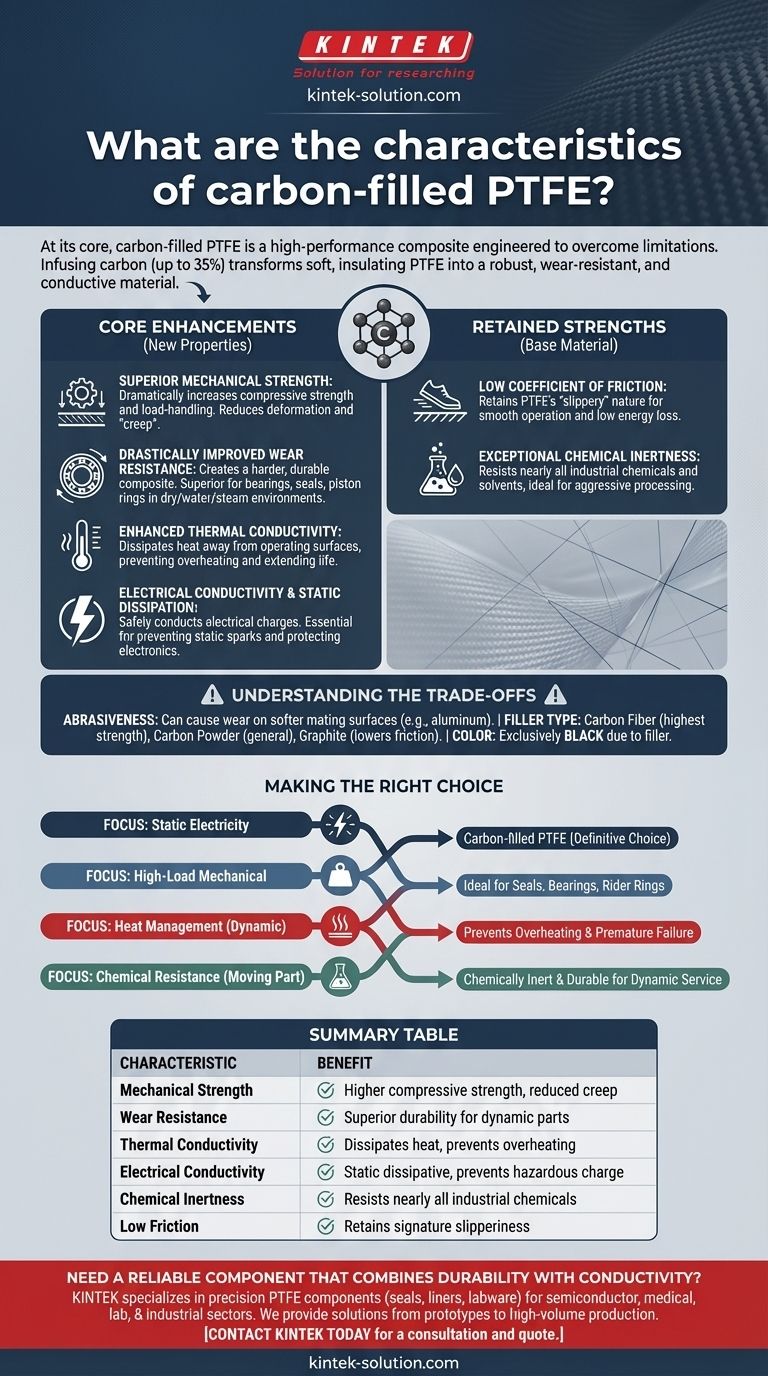

At its core, carbon-filled Polytetrafluoroethylene (PTFE) is a high-performance composite material engineered to overcome the mechanical limitations of virgin PTFE. By infusing carbon (typically up to 35%) into the PTFE matrix, it gains significantly improved strength, wear resistance, and thermal and electrical conductivity, all while retaining PTFE's signature low friction and chemical inertness.

The fundamental problem with pure PTFE is its softness and its nature as an excellent insulator. Adding carbon filler transforms it into a mechanically robust, wear-resistant, and conductive material ideal for demanding applications where load, friction, and static electricity are critical concerns.

The Core Enhancements of Carbon Filler

Adding carbon is not just about reinforcement; it fundamentally changes the material's behavior in response to mechanical, thermal, and electrical stress.

Superior Mechanical Strength

Carbon filler dramatically increases the compressive strength and load-handling capabilities of PTFE.

This enhancement reduces deformation and "creep" (the tendency of a material to slowly deform under a constant load), making it suitable for components under heavy pressure.

Drastically Improved Wear Resistance

This is one of the primary reasons for choosing carbon-filled PTFE. The carbon particles create a harder, more durable composite.

It offers superior wear resistance in dynamic applications like bearings, seals, and piston rings, especially in dry, water, or steam environments.

Enhanced Thermal Conductivity

Virgin PTFE is a thermal insulator, which can be a problem in high-friction applications where heat can build up.

Carbon is an excellent thermal conductor. Its presence allows the material to dissipate heat away from the operating surface, preventing overheating and extending the life of the component.

Electrical Conductivity and Static Dissipation

Perhaps the most unique property is its electrical conductivity. Pure PTFE is an excellent electrical insulator, which allows static charge to build up on its surface.

Carbon-filled PTFE is static dissipative, meaning it safely conducts electrical charges away. This makes it essential for applications where a static spark could be hazardous or disrupt sensitive electronics.

Retaining the Fundamental Strengths of PTFE

The genius of this composite is that it gains new properties without sacrificing the most valuable characteristics of the base material.

Low Coefficient of Friction

Despite the addition of a reinforcing filler, the material retains an impressively low coefficient of friction.

It remains inherently "slippery," ensuring smooth operation and low energy loss in moving parts.

Exceptional Chemical Inertness

Carbon is a chemically neutral filler. The resulting composite retains PTFE's legendary resistance to nearly all industrial chemicals and solvents.

This makes it a reliable choice for seals and components used in aggressive chemical processing environments.

Understanding the Trade-offs

While highly capable, no material is perfect. A clear understanding of the limitations is crucial for proper application.

Abrasiveness to Mating Surfaces

While carbon is noted to be less abrasive than glass filler, it is still harder than pure PTFE.

In dynamic applications, carbon-filled PTFE can cause wear on softer mating surfaces (like aluminum or softer steels) over time. Careful selection of the opposing material is important.

Filler Type and Form

The type of carbon used matters. Carbon fiber provides the greatest mechanical strength and stiffness. Carbon powder (amorphous carbon) provides good general-purpose enhancement.

Some grades also include graphite, which further lowers the coefficient of friction and improves self-lubricating properties, making them ideal for compressor components like piston rings.

Color

Due to the filler, carbon-filled PTFE is exclusively black. This can be a limiting factor in applications where color-coding or aesthetics are required.

Making the Right Choice for Your Application

Selecting the correct material grade depends entirely on the primary problem you need to solve.

- If your primary focus is eliminating static electricity: Carbon-filled PTFE is the definitive choice due to its inherent static dissipative properties.

- If your primary focus is high-load mechanical performance: Its improved compressive strength and wear resistance make it ideal for seals, bearings, and rider rings.

- If your primary focus is managing heat in a dynamic part: Its enhanced thermal conductivity will help prevent overheating and premature failure.

- If your primary focus is chemical resistance in a moving part: This material provides PTFE's chemical inertness combined with the durability required for dynamic service.

By understanding these characteristics, you can confidently specify carbon-filled PTFE for applications where virgin plastics would fail.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Mechanical Strength | Higher compressive strength, reduced creep under load |

| Wear Resistance | Superior durability for bearings, seals, and piston rings |

| Thermal Conductivity | Dissipates heat, preventing overheating in dynamic parts |

| Electrical Conductivity | Static dissipative, prevents hazardous charge buildup |

| Chemical Inertness | Resists nearly all industrial chemicals and solvents |

| Low Friction | Retains PTFE's signature slipperiness for smooth operation |

Need a reliable component that combines durability with conductivity?

KINTEK specializes in manufacturing precision PTFE components, including custom carbon-filled PTFE seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, providing solutions from prototypes to high-volume production.

Our expertise ensures you get a component that meets your exact requirements for strength, wear resistance, and static control. Let's discuss how our custom fabrication can solve your specific application challenge.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments