In short, expanded PTFE (ePTFE) gaskets are the premier choice for applications where a reliable seal must be achieved with low clamping force or on imperfect surfaces. They are specifically suited for sealing fragile glass or plastic flanges, irregular or damaged metal flanges, and systems handling aggressive chemicals where standard gaskets would fail.

The core value of an ePTFE gasket is not just its chemical inertness, but its exceptional softness and conformability. This allows it to solve sealing challenges that are impossible for harder, more rigid gasket materials.

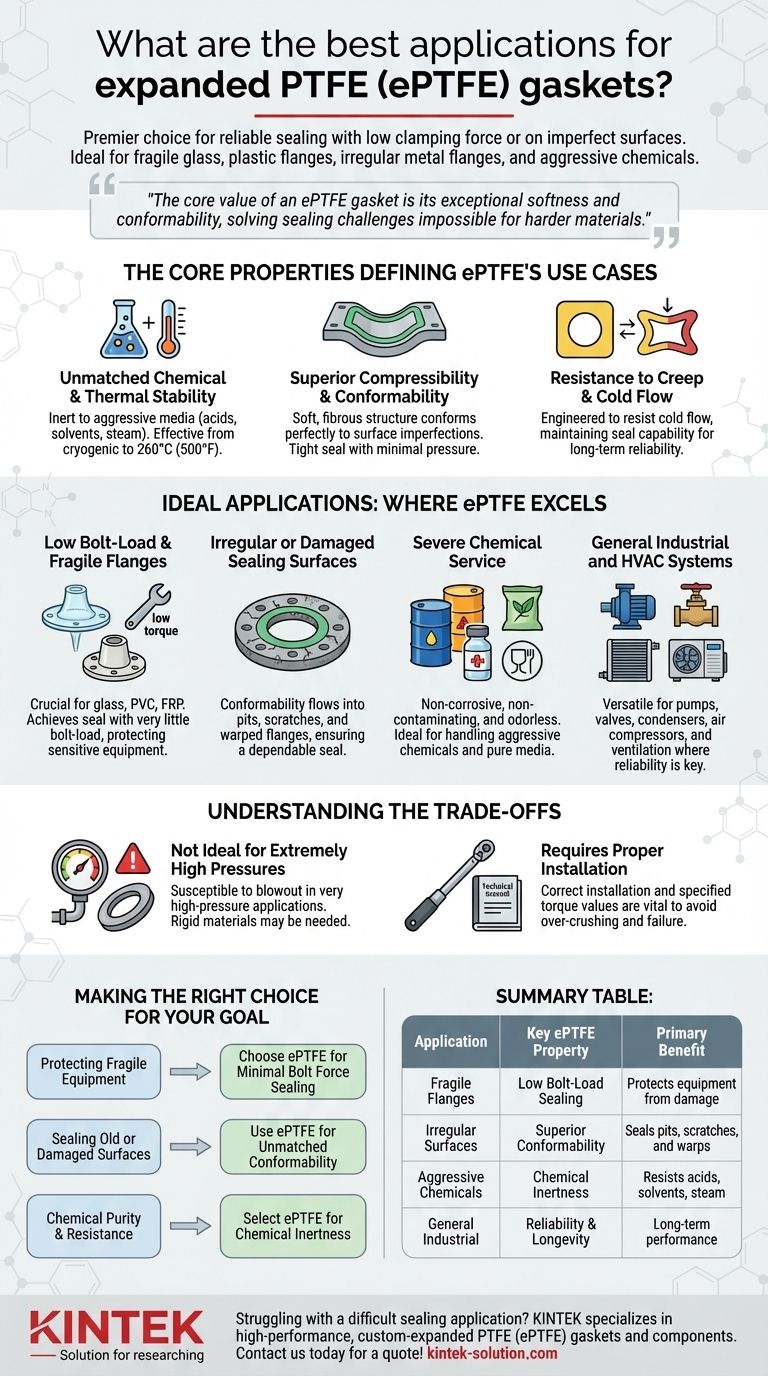

The Core Properties Defining ePTFE's Use Cases

To understand where ePTFE excels, you must first understand its fundamental material properties. These characteristics directly translate into its ideal applications.

Unmatched Chemical & Thermal Stability

Expanded PTFE inherits the legendary chemical resistance of standard PTFE. It is inert to a vast range of aggressive media, including caustic chemicals, acids, solvents, hydrocarbons, and steam.

This material also performs across an extremely wide temperature range, remaining effective from cryogenic conditions up to 260°C (500°F).

Superior Compressibility and Conformability

The "expansion" process creates a soft, multidirectionally fibrous structure. This makes the material highly compressible, allowing it to conform perfectly to surface imperfections like scratches, pits, or warped flanges.

This softness is the key to creating a tight seal with minimal pressure.

Resistance to Creep and Cold Flow

A common failure point for lesser materials is creep relaxation, where a gasket slowly deforms under pressure and loses its seal over time.

ePTFE is engineered to resist this cold flow, ensuring it maintains its shape and sealing capability for long-term, reliable service.

Ideal Applications: Where ePTFE Excels

These material properties make ePTFE the definitive solution for several specific and challenging sealing scenarios.

Low Bolt-Load and Fragile Flanges

This is the most critical application for ePTFE. Equipment made from glass, PVC, or fiberglass-reinforced plastic (FRP) can easily crack under the high bolt torque required by other gaskets.

Because ePTFE is so soft, it achieves a reliable seal with very little bolt-load, protecting fragile and stress-sensitive equipment from damage.

Irregular or Damaged Sealing Surfaces

Older pipelines, heat exchangers, and pressure vessels often have flange surfaces that are no longer perfectly flat.

The exceptional conformability of ePTFE allows it to flow into these imperfections, creating a dependable seal where a rigid gasket would inevitably leak.

Severe Chemical Service

In chemical processing, pharmaceutical, and food-grade applications, preventing contamination and chemical attack is paramount.

ePTFE's non-corrosive, non-contaminating, and odorless nature, combined with its broad chemical resistance, makes it ideal for handling everything from pure water and steam to hydrogen peroxide and aggressive acids.

General Industrial and HVAC Systems

Beyond specialized cases, ePTFE is a versatile workhorse in many common industrial systems.

It is frequently used in pumps, valves, condensers, air compressors, and ventilation systems where reliability and longevity are key operational requirements.

Understanding the Trade-offs

While ePTFE is a powerful problem-solver, it is not a universal solution. Its primary strength—softness—also defines its limitations.

Not Ideal for Extremely High Pressures

The same softness that allows ePTFE to seal with low force can make it susceptible to extrusion or "blowout" in extremely high-pressure applications, especially if the flange design is not optimized.

In such cases, a more rigid gasket material, potentially a metal or composite type, may be necessary. Always verify the gasket's pressure rating against your system's requirements.

Requires Proper Installation

While easier to cut and handle than pure PTFE, correct installation is still vital. Overtightening can crush the material, reducing its effectiveness and potentially causing it to extrude from the flange.

Following the manufacturer's specified torque values is essential to leverage the material's benefits without causing premature failure.

Making the Right Choice for Your Goal

Select your gasket based on the primary problem you need to solve.

- If your primary focus is protecting fragile equipment: Choose ePTFE for its ability to create a seal with minimal bolt force, preventing damage to glass, plastic, or FRP flanges.

- If your primary focus is sealing old or damaged surfaces: Use ePTFE for its unmatched ability to conform to pits, scratches, and warped flanges, ensuring a leak-free connection.

- If your primary focus is chemical purity and resistance: Select ePTFE for its chemical inertness, making it a safe and reliable choice for food-grade, pharmaceutical, or aggressive media applications.

Ultimately, choosing an ePTFE gasket is a decision to prioritize a reliable, long-term seal in mechanically or chemically demanding situations.

Summary Table:

| Application | Key ePTFE Property | Primary Benefit |

|---|---|---|

| Fragile Flanges (Glass, Plastic) | Low Bolt-Load Sealing | Protects equipment from damage |

| Irregular/Damaged Surfaces | Superior Conformability | Seals pits, scratches, and warps |

| Aggressive Chemical Service | Chemical Inertness | Resists acids, solvents, and steam |

| General Industrial Systems | Reliability & Longevity | Long-term performance in pumps, valves, HVAC |

Struggling with a difficult sealing application? KINTEK specializes in manufacturing high-performance, custom-expanded PTFE (ePTFE) gaskets and components. Our expertise in precision fabrication ensures you get a solution perfectly tailored to your needs—whether you're protecting fragile glassware in a lab, sealing an old pipeline in an industrial plant, or handling aggressive chemicals in a semiconductor process. We deliver from prototypes to high-volume orders with a focus on quality and reliability. Let our team solve your sealing challenge—contact us today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries