At their core, PTFE lined pipes offer a powerful combination of near-universal chemical resistance, an exceptionally low-friction surface, and outstanding durability. This makes them a premier solution for safely and efficiently transporting aggressive, corrosive, or high-purity fluids that would quickly degrade standard piping systems.

The fundamental value of a PTFE lined pipe isn't just its material properties; it's the operational reliability it provides. By creating an inert, non-stick barrier, it protects the structural steel pipe from the inside out, preventing catastrophic failures, costly downtime, and product contamination.

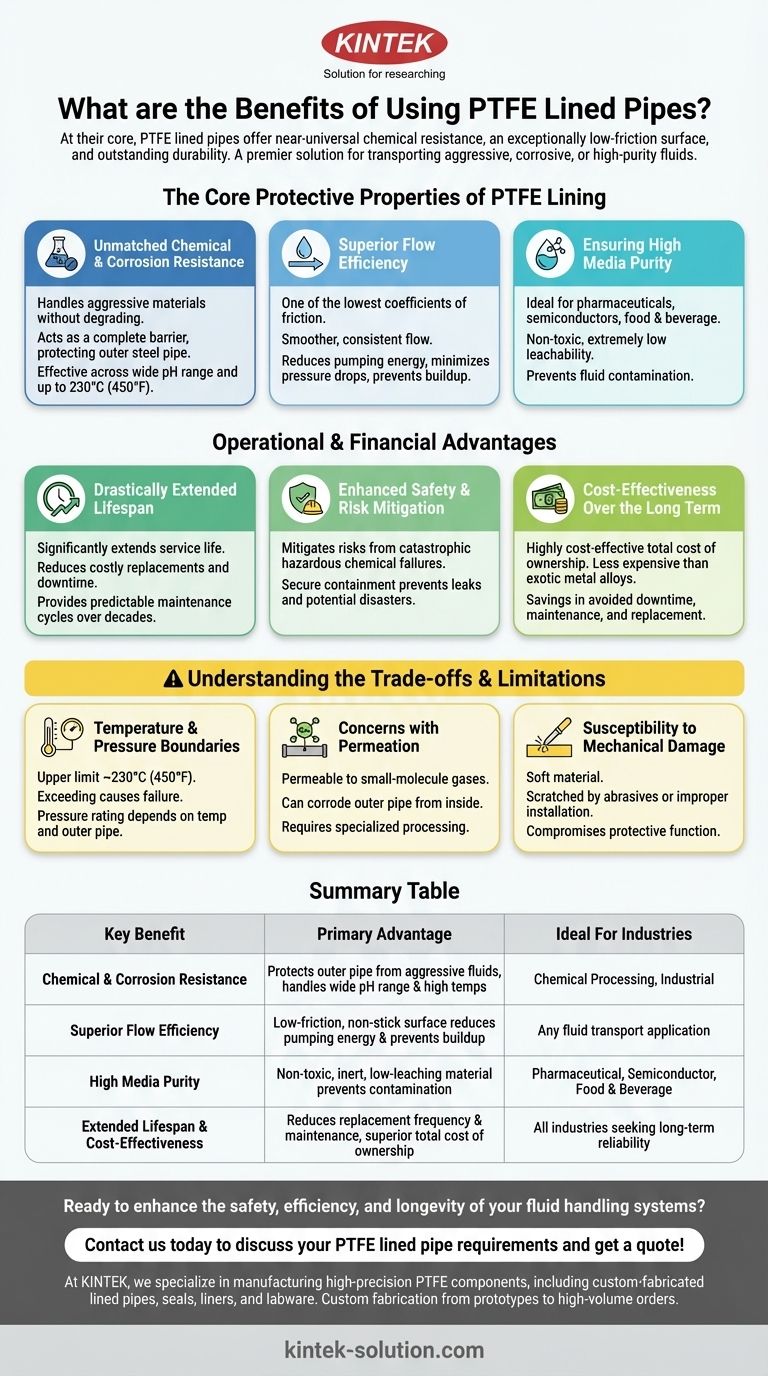

The Core Protective Properties of PTFE Lining

The benefits of PTFE stem from its unique molecular structure, which provides a robust defense against common industrial challenges. This protection translates directly into system integrity and performance.

Unmatched Chemical and Corrosion Resistance

Polytetrafluoroethylene (PTFE) is one of the most chemically inert substances known. This means it can handle a vast range of aggressive materials without degrading.

The liner acts as a complete barrier, protecting the outer carbon or stainless steel pipe from any contact with the corrosive fluid. This property holds true across a wide pH range and at elevated temperatures, often up to 230°C (450°F).

Superior Flow Efficiency

PTFE has one of the lowest coefficients of friction of any solid, creating a non-stick surface that is superior to even wet ice on wet ice.

This property ensures a much smoother, more consistent flow of media through the pipe. It reduces the energy needed for pumping, minimizes pressure drops over long distances, and prevents materials from building up on the pipe walls.

Ensuring High Media Purity

In industries like pharmaceuticals, semiconductors, or food and beverage, preventing contamination is critical. PTFE is an ideal choice for these high-purity applications.

Because it is non-toxic and has extremely low leachability, the PTFE liner will not contaminate the fluid it is transporting. This ensures the final product meets stringent quality and safety standards.

Operational and Financial Advantages

Beyond its technical performance, choosing PTFE lined pipe is a strategic decision that impacts safety, maintenance schedules, and long-term budgets.

Drastically Extended Lifespan

By shielding the structural pipe from corrosion, PTFE lining significantly extends the service life of the entire pipeline.

This longevity reduces the frequency of costly replacements, minimizes process shutdowns, and provides a more predictable maintenance cycle over decades of use.

Enhanced Safety and Risk Mitigation

A pipeline failure involving hazardous chemicals can be catastrophic, posing risks to personnel, the environment, and equipment.

The reliability of PTFE lining directly mitigates this risk. It provides a secure containment system for corrosive acids, solvents, and other dangerous substances, preventing leaks and potential disasters.

Cost-Effectiveness Over the Long Term

While the initial investment may be higher than for basic steel pipe, PTFE lined pipe is a highly cost-effective solution when viewed through the lens of total cost of ownership.

It is significantly less expensive than using pipes made entirely of exotic metal alloys (like Hastelloy or Monel) while offering comparable or superior chemical resistance. The savings in avoided downtime, maintenance, and replacement costs provide a strong return on investment.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined pipe is not a universal solution. Understanding its limitations is key to successful implementation and avoiding common pitfalls.

Temperature and Pressure Boundaries

PTFE has a firm upper-temperature limit, typically around 230°C (450°F). Exceeding this can cause the liner to degrade or lose its mechanical properties, leading to failure. The pressure rating is also dependent on the temperature and the specifications of the outer steel pipe.

Concerns with Permeation

While PTFE is a fantastic liquid barrier, it is not entirely impermeable to certain small-molecule gases (like chlorine, bromine, or hydrogen chloride). Over time, these gases can permeate through the liner and become trapped, where they can then corrode the outer steel pipe from the inside. Specialized processing or venting systems may be required for these specific services.

Susceptibility to Mechanical Damage

The PTFE liner is a relatively soft material. It can be scratched or gouged by highly abrasive slurries or damaged by improper installation techniques. Any breach in the liner completely compromises its protective function, exposing the steel pipe to the corrosive media.

Making the Right Choice for Your Application

Selecting the correct piping system depends entirely on the specific demands of your process.

- If your primary focus is handling aggressive chemicals: PTFE lining is an industry-standard choice for safely containing corrosive fluids and protecting your capital assets from chemical attack.

- If your primary focus is maintaining high media purity: The inert, non-toxic, and low-leaching nature of PTFE makes it an essential component for pharmaceutical, food-grade, or electronics manufacturing.

- If your primary focus is reducing long-term operational costs: The exceptional lifespan and low maintenance needs of PTFE lined pipe offer a superior total cost of ownership compared to less-durable materials that require frequent replacement.

Ultimately, specifying PTFE lined pipe is an investment in the long-term safety, efficiency, and reliability of your critical fluid handling systems.

Summary Table:

| Key Benefit | Primary Advantage | Ideal For Industries |

|---|---|---|

| Chemical & Corrosion Resistance | Protects outer pipe from aggressive fluids, handles wide pH range and high temps | Chemical Processing, Industrial |

| Superior Flow Efficiency | Low-friction, non-stick surface reduces pumping energy and prevents buildup | Any fluid transport application |

| High Media Purity | Non-toxic, inert, low-leaching material prevents contamination | Pharmaceutical, Semiconductor, Food & Beverage |

| Extended Lifespan & Cost-Effectiveness | Reduces replacement frequency and maintenance, superior total cost of ownership | All industries seeking long-term reliability |

Ready to enhance the safety, efficiency, and longevity of your fluid handling systems?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated lined pipes, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your systems are protected against corrosive chemicals, maintain high purity, and operate reliably for years to come.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific application needs. Don't let pipeline failures or contamination risks compromise your operations.

Contact us today to discuss your PTFE lined pipe requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries