Ultimately, the primary benefit of PTFE gasket sheet material is its exceptional versatility, stemming from a unique combination of chemical inertness, a vast operational temperature range, and physical adaptability. This makes it a uniquely reliable sealing solution for some of the most demanding industrial, food-grade, and pharmaceutical applications where other materials would fail.

PTFE's value isn't just in a single property, but in its rare ability to solve multiple challenges at once. It simultaneously resists aggressive chemicals and extreme temperatures while providing a safe, clean, and reliable seal on even imperfect surfaces.

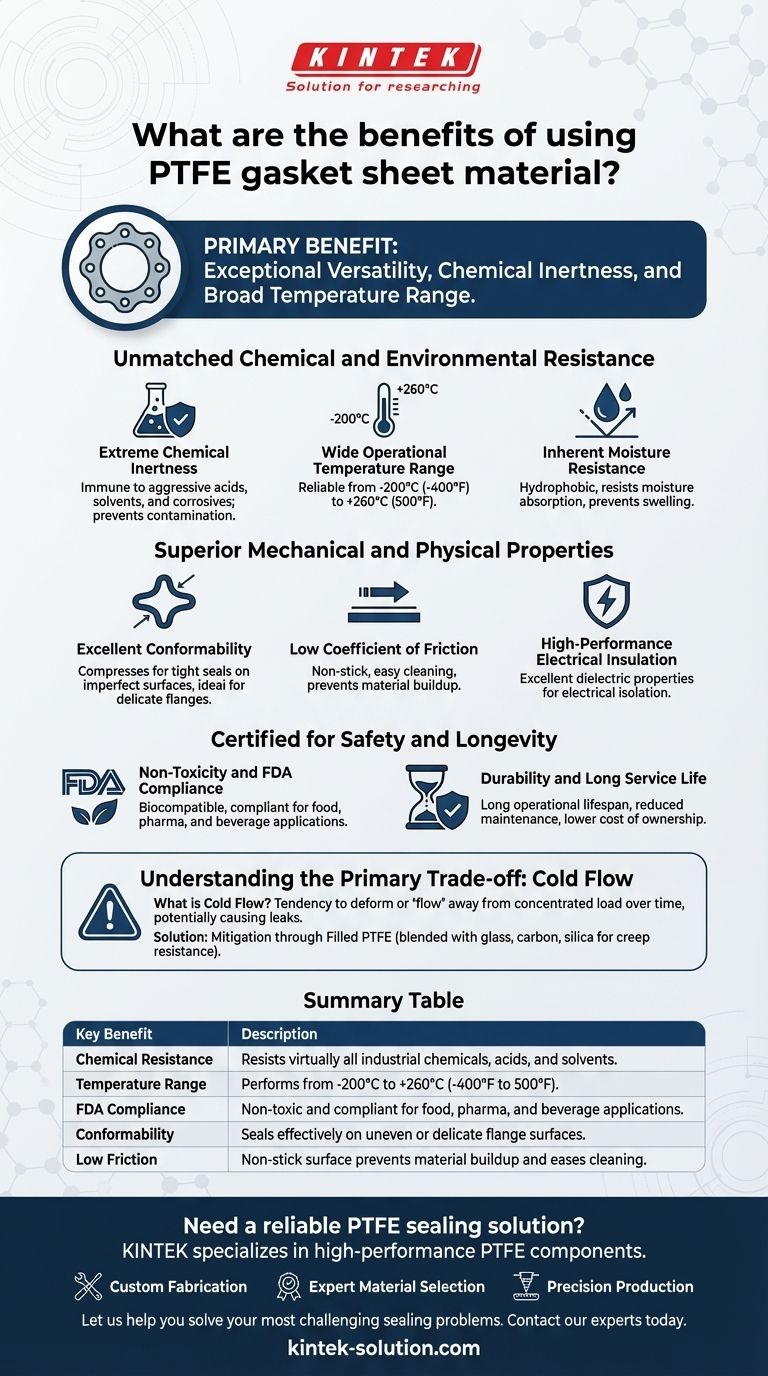

Unmatched Chemical and Environmental Resistance

One of the most significant advantages of Polytetrafluoroethylene (PTFE) is its ability to withstand hostile environments without degrading. This resilience is fundamental to its role in critical applications.

Extreme Chemical Inertness

PTFE is virtually immune to almost all industrial chemicals, including aggressive acids, solvents, and corrosive agents. This non-reactive nature ensures the integrity of the seal and prevents contamination of the process media.

Wide Operational Temperature Range

This material performs reliably across an exceptionally broad temperature spectrum. It remains effective in cryogenic conditions as low as -200°C (-400°F) and can handle continuous service temperatures up to +260°C (500°F).

Inherent Moisture Resistance

PTFE is hydrophobic, meaning it repels water and resists moisture absorption. This property prevents the gasket from swelling or degrading in humid or wet environments, ensuring a stable and long-lasting seal.

Superior Mechanical and Physical Properties

Beyond its chemical resilience, PTFE's physical characteristics make it an excellent choice for creating and maintaining a tight seal between flange surfaces.

Excellent Conformability

PTFE sheet is compressible and flexible, allowing it to conform perfectly to irregular, scratched, or uneven flange surfaces. This adaptability ensures a tight seal with minimal bolt load, which is especially useful for delicate glass-lined or plastic flanges.

Low Coefficient of Friction

Known for its non-stick properties, PTFE has one of the lowest coefficients of friction of any solid material. This makes for easy cleaning and helps prevent material buildup on the gasket surface.

High-Performance Electrical Insulation

PTFE is an outstanding electrical insulator with excellent dielectric properties. This makes it a safe and ideal choice for applications where electrical isolation between flanges is required.

Certified for Safety and Longevity

In industries where purity and reliability are non-negotiable, PTFE provides a proven and certified solution that ensures both safety and a long service life.

Non-Toxicity and FDA Compliance

PTFE is non-toxic and biocompatible, and many grades comply with FDA and NSF regulations. This makes it the default choice for gaskets used in the food, beverage, drinking water, and pharmaceutical industries.

Durability and Long Service Life

The combination of chemical resistance, temperature stability, and physical resilience gives PTFE gaskets a very long operational lifespan. This durability reduces maintenance frequency and lowers the total cost of ownership.

Understanding the Primary Trade-off: Cold Flow

While PTFE is an exceptional material, its primary limitation is a phenomenon known as creep or cold flow. Understanding this is critical for its successful application.

What is Cold Flow?

Cold flow is the tendency of a soft material like PTFE to slowly deform or "flow" away from a concentrated load over time. Under the compressive force of a bolted flange, the gasket material can slowly thin out, leading to a loss of bolt torque and a potential leak path.

When is it a Concern?

This issue is most prominent in applications involving high pressures, high temperatures, and significant thermal cycling. In these conditions, the bolt load can relax, compromising the integrity of the seal.

Mitigation through Filled PTFE

To combat cold flow, PTFE is often blended with filler materials like glass, carbon, or silica. These "filled" PTFE variants offer significantly improved creep resistance while retaining most of the base material's desirable properties.

Making the Right Choice for Your Goal

Selecting the right gasket material requires matching its properties to your specific operational needs.

- If your primary focus is aggressive chemical sealing: PTFE is one of the most chemically resistant materials available, making it a superior choice for acids, solvents, and caustics.

- If your primary focus is food, beverage, or pharmaceutical purity: Choose an FDA-compliant grade of PTFE to ensure a non-toxic, non-contaminating, and cleanable seal.

- If your primary focus is sealing delicate or uneven flanges: The excellent compressibility of PTFE allows it to create a reliable seal on imperfect surfaces with lower bolt torque.

- If your primary focus is high-pressure or high-temperature service: Consider a filled PTFE variant to mitigate the risk of cold flow and ensure a long-term, stable seal.

By understanding its core strengths and its key limitation, you can confidently specify PTFE for your most critical sealing requirements.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Resistance | Resists virtually all industrial chemicals, acids, and solvents. |

| Temperature Range | Performs from -200°C to +260°C (-400°F to 500°F). |

| FDA Compliance | Non-toxic and compliant for food, pharma, and beverage applications. |

| Conformability | Seals effectively on uneven or delicate flange surfaces. |

| Low Friction | Non-stick surface prevents material buildup and eases cleaning. |

Need a reliable PTFE sealing solution tailored to your specific requirements?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including gaskets, seals, liners, and custom labware. Whether you're in the semiconductor, medical, pharmaceutical, laboratory, or industrial sector, we understand the critical need for seals that offer uncompromising chemical resistance, purity, and durability.

We provide:

- Custom Fabrication: From prototypes to high-volume production runs.

- Expert Material Selection: Guidance on standard or filled PTFE grades to combat cold flow in high-pressure/temperature applications.

- Precision Production: Ensuring every component meets your exact specifications for a perfect, reliable seal.

Let us help you solve your most challenging sealing problems. Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components