The primary benefit of Teflon's self-lubricating properties is a dramatic reduction in friction and wear between moving parts. This inherent characteristic allows mechanical components to slide smoothly against each other without the need for external lubricants like grease or oil, which in turn extends component life, reduces maintenance, and improves overall system performance.

The core value of Teflon's self-lubrication is not just its slipperiness, but its ability to fundamentally simplify mechanical design. By eliminating the dependence on external lubricants, it creates systems that are cleaner, more reliable, and less costly to operate over their lifespan.

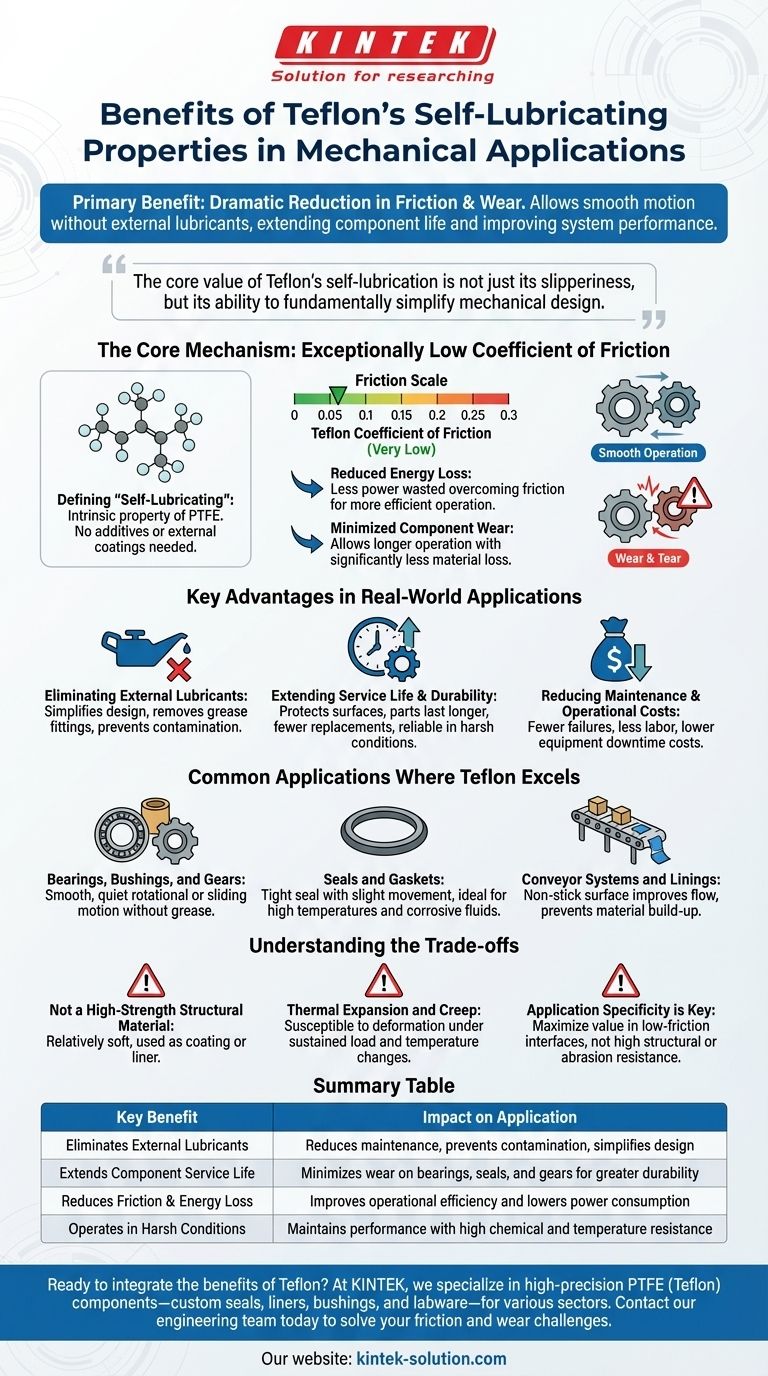

The Core Mechanism: An Exceptionally Low Coefficient of Friction

Defining "Self-Lubricating"

Teflon's self-lubricating nature is an intrinsic property of the material itself, scientifically known as Polytetrafluoroethylene (PTFE). It does not require any additive or external coating to achieve its low-friction surface.

The Impact on Friction and Energy

Teflon possesses an extremely low coefficient of friction, typically between 0.05 and 0.15. This means very little energy is required to move a Teflon surface against another material.

In a mechanical system, this translates directly to reduced energy loss. Less power is wasted overcoming friction, leading to more efficient operation.

The Impact on Component Wear

Friction is the primary driver of wear and degradation in moving parts. By minimizing this friction, Teflon allows components to operate for longer periods with significantly less material loss.

This property is critical for extending the service life of parts like bearings, seals, and gears, which are in constant motion.

Key Advantages in Real-World Applications

Eliminating External Lubricants

The most significant operational benefit is the elimination of external lubrication. This simplifies system design and removes the need for grease fittings, oil reservoirs, and scheduled lubrication tasks.

This is especially valuable in applications where contamination is a concern, such as in food processing or medical equipment, or in locations that are difficult to access for maintenance.

Extending Service Life and Durability

By protecting surfaces from wear, Teflon coatings and components directly contribute to longer equipment life. Parts last longer, replacement cycles are extended, and overall system reliability is improved.

This durability holds true even in harsh conditions, as Teflon is also highly resistant to chemicals and high temperatures.

Reducing Maintenance and Operational Costs

Fewer component failures and the removal of lubrication tasks lead to a direct reduction in maintenance requirements.

This results in lower costs associated with labor, replacement parts, and equipment downtime, making Teflon a cost-effective choice over the long term.

Common Applications Where Teflon Excels

Bearings, Bushings, and Gears

These are classic applications where reducing friction is the primary goal. Teflon allows for smooth, quiet, and reliable rotational or sliding motion without the mess and complexity of grease.

Seals and Gaskets

Teflon's ability to create a tight seal while still allowing for slight movement makes it ideal for sealing applications, especially in high-temperature environments. Its chemical resistance ensures the seal maintains integrity when exposed to corrosive fluids.

Conveyor Systems and Linings

In material handling, Teflon is used to coat conveyor belts, chutes, and hoppers. Its non-stick, low-friction surface ensures that materials slide easily without building up, improving flow and efficiency.

Understanding the Trade-offs

Not a High-Strength Structural Material

While its surface properties are exceptional, Teflon is a relatively soft material. It is not intended for high-load structural applications and is typically used as a coating, liner, or specific component within a larger, stronger assembly.

Thermal Expansion and Creep

Like many polymers, Teflon can be susceptible to thermal expansion and "creep" (slow deformation) under a sustained load. These factors must be accounted for in precise engineering designs to ensure tolerances are maintained over time and across temperature ranges.

Application Specificity is Key

The benefits of Teflon are maximized when it is applied correctly. Its primary value is in low-friction interfaces, not in situations requiring high structural rigidity or abrasion resistance against sharp, hard particles.

Making the Right Choice for Your Application

Choosing a material always depends on the primary engineering goal. Teflon's self-lubricating properties make it an outstanding choice for specific challenges.

- If your primary focus is maintenance reduction and system cleanliness: Teflon is the ideal choice for eliminating wet lubricants and their associated costs and contamination risks.

- If your primary focus is energy efficiency: The ultra-low friction coefficient directly reduces the energy wasted in your system, improving overall performance.

- If your primary focus is component longevity in harsh environments: Teflon's combination of self-lubrication and chemical resistance provides unparalleled durability for seals, bearings, and other critical parts.

Ultimately, leveraging Teflon's self-lubricating properties allows you to design and build more robust, efficient, and reliable mechanical systems.

Summary Table:

| Key Benefit | Impact on Application |

|---|---|

| Eliminates External Lubricants | Reduces maintenance, prevents contamination, simplifies design |

| Extends Component Service Life | Minimizes wear on bearings, seals, and gears for greater durability |

| Reduces Friction & Energy Loss | Improves operational efficiency and lowers power consumption |

| Operates in Harsh Conditions | Maintains performance with high chemical and temperature resistance |

Ready to integrate the benefits of Teflon into your mechanical systems?

At KINTEK, we specialize in manufacturing high-precision PTFE (Teflon) components—including custom seals, liners, bushings, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to your specific needs for reduced maintenance, improved efficiency, and extended equipment life.

Contact our engineering team today to discuss how our PTFE components can solve your friction and wear challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers